Preparation and application of a stable pituitary flavor tobacco essence

A cigarette flavor and stable technology, which is applied in the field of compound and stable cigarette flavor preparation, can solve problems such as uneven fragrance release, and achieve the effects of uniform fragrance release, increasing sweet and moist bottom taste, and stable and long-lasting fragrance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

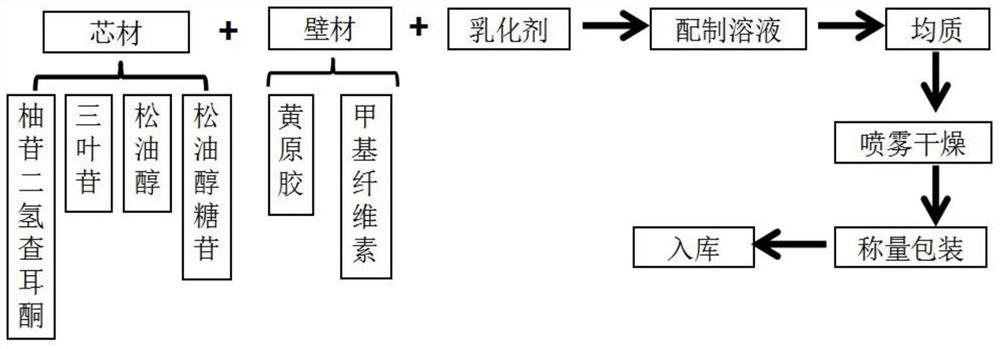

Method used

Image

Examples

Embodiment 1

[0026] Weigh 1 part by weight of naringin dihydrochalcone, 1 part by weight of trilobatin, 8 parts by weight of terpineol, and mix 8 parts by weight of terpineol glycoside; Cellulose, mix well; mix the two mixtures according to the weight ratio of core material to wall material 3:1. Weigh 0.5wt% of stearyl monoglyceride citrate in the total weight of the wall material and the core material and mix it with the wall material core material; add water to the mixture and stir to prepare a 30wt% aqueous dispersion; homogenize at 60°C and 25MPa, A uniform water dispersion is obtained; and the stable tobacco essence is obtained by spraying and drying. Tobacco essence is added to the tobacco, and the cigarette is rolled after balancing.

Embodiment 2

[0028] Take by weighing 3 parts by weight of naringin dihydrochalcone, 3 parts by weight of trilobatin, 5 parts by weight of terpineol, and 5 parts by weight of terpineol glycoside and mix uniformly; Cellulose, mix well; mix the two mixtures according to the weight ratio of 1:1 for core material and wall material. Weigh 1.0wt% stearyl monoglyceride citrate and mix it with the wall material and core material by weighing the total weight of the wall material and the core material; add water to the mixture and stir to prepare a 40wt% aqueous dispersion; A uniform water dispersion is obtained; and the stable tobacco essence is obtained by spraying and drying. Tobacco essence is added to the tobacco, and the cigarette is rolled after balancing.

Embodiment 3

[0030] Take by weighing 2 parts by weight of naringin dihydrochalcone, 2 parts by weight of trilobatin, 6 parts by weight of terpineol, and 6 parts by weight of terpineol glycoside and mix evenly; Cellulose, mix well; mix the two mixtures according to the weight ratio of 1:1 for core material and wall material. Weigh 1.0wt% of stearyl monoglyceride citrate in the total weight of the wall material and the core material and mix it with the wall material core material; add water to the mixture and stir to prepare a 35wt% aqueous dispersion; homogenize at 65°C and 30MPa, A uniform water dispersion is obtained; and the stable tobacco essence is obtained by spraying and drying. Tobacco essence is added to the tobacco, and the cigarette is rolled after balancing.

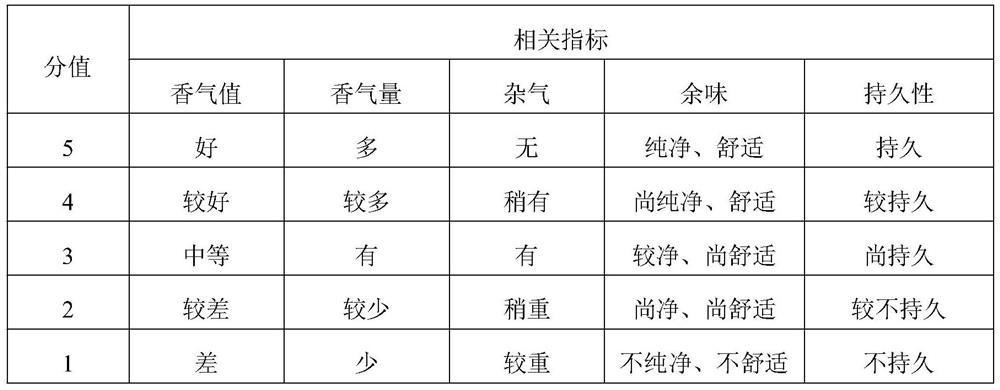

[0031] Using the stable tobacco essence of the present invention to add it to shredded cigarettes, compared with the cigarettes added with ordinary tobacco essence, 10 professionals were selected to evaluate and score the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com