Flue gas analysis device

A flue gas analysis and gas pump technology, applied in the field of boilers, can solve the problems of short life, unfavorable energy saving, and inability to use for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

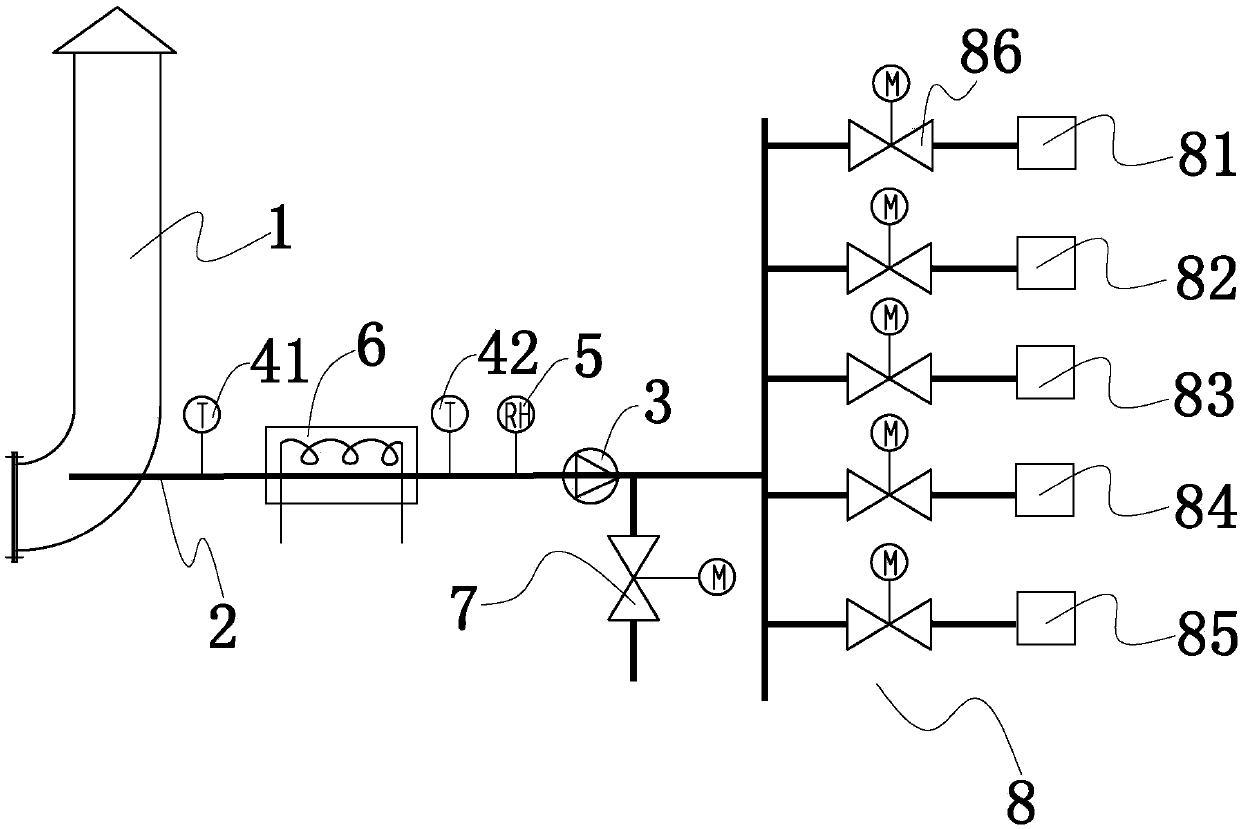

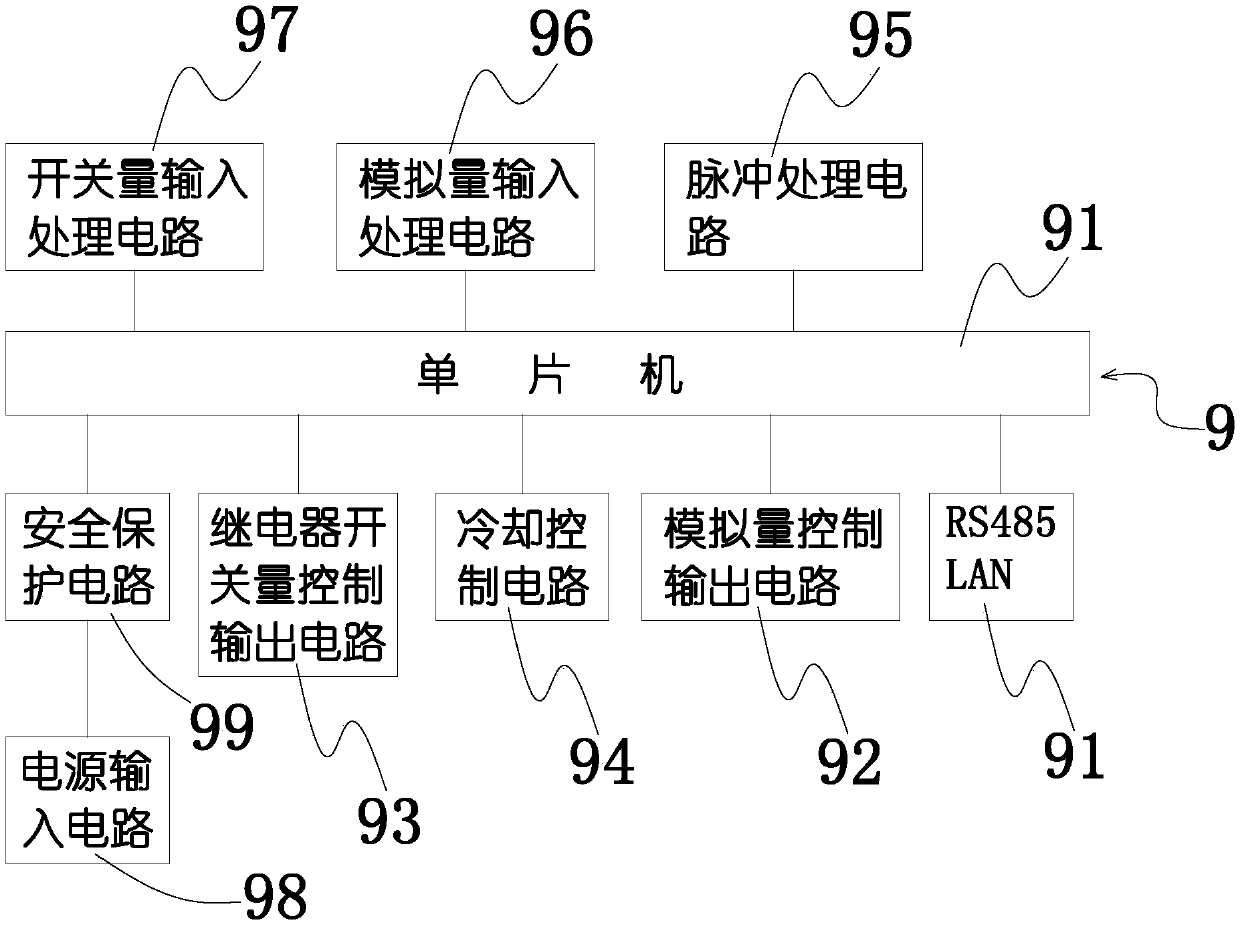

[0029] Such as figure 1 and figure 2As shown, a flue gas analysis device includes a gas pipe 2, an air pump 3, a first temperature sensor 41, a second temperature sensor 42, a humidity sensor 5, a cooler 6, a first solenoid valve 7, a detection module 8 and a control module 9 , the air pipe 2 includes an air intake pipe, one end of the air intake pipe extends into the boiler exhaust gas discharge pipe 1, and the other end is installed on the air intake end of the air pump 3, the first temperature sensor 41, the second temperature sensor 42, the humidity sensor 5 and the cooler 6 are connected in series Connected to the intake pipe, the first temperature sensor 41 is connected in series between the boiler exhaust gas discharge pipe 1 and the cooler 6. The cooler 6 can be an air-cooled cooler or a semiconductor refrigeration cooler. In this embodiment, an air-cooled cooler is preferred. The second temperature sensor 42 and the humidity sensor 5 are connected in series between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com