Sewage purification system and method

A sewage purification and sewage technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of high equipment cost, high equipment input cost, and high transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

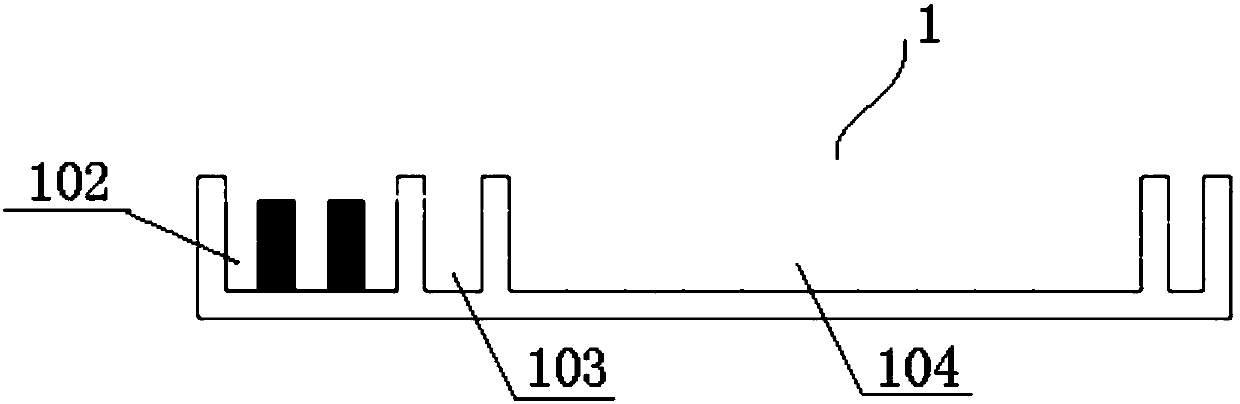

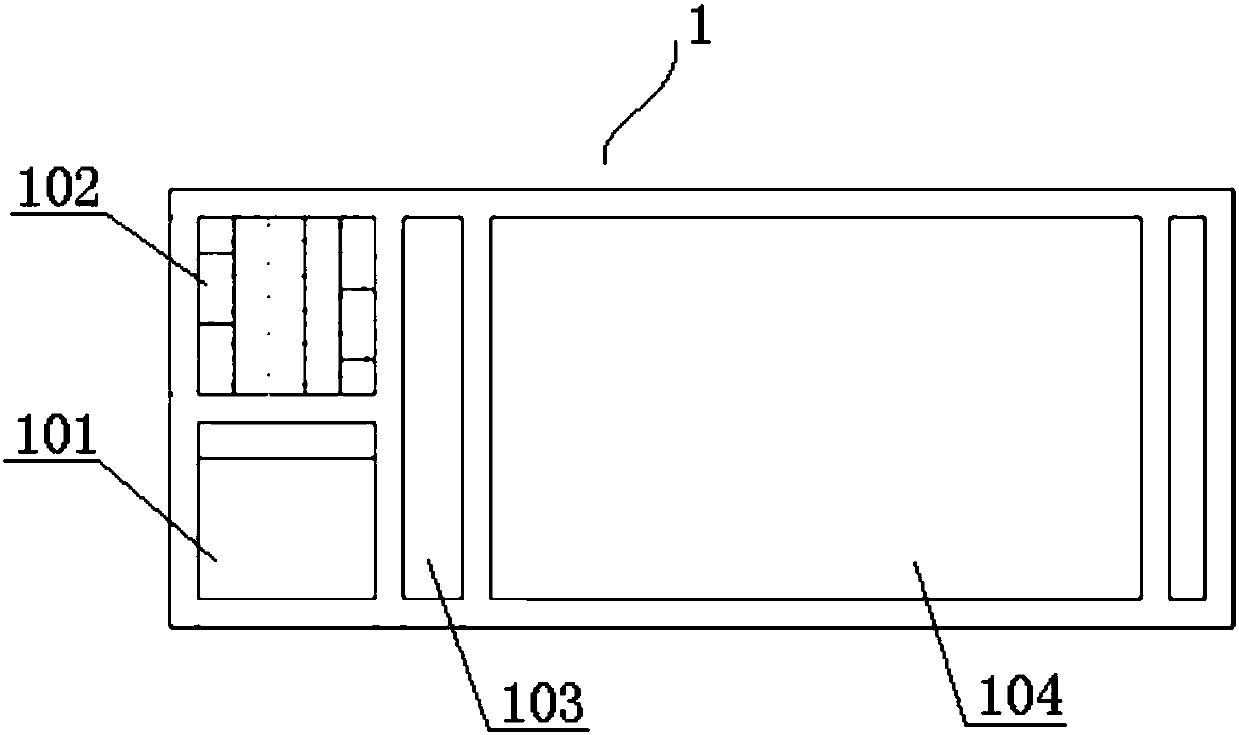

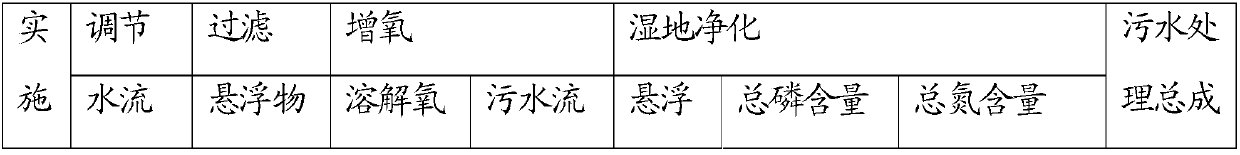

[0029] See figure 1 with figure 2 as shown, figure 1 is a schematic diagram of a sewage purification system according to an embodiment of the present invention; figure 2 yes figure 1 top view. use figure 1 with figure 2 The sewage purification system 1 of the embodiment shown includes a regulating pond 101, a filtering pond 102, an aeration pond 103 and a wetland purification pond 104 connected in sequence; the regulating pond 101 collects sewage, and controls the speed at which the sewage flows out to [1.5, 2 ] ton / day; the filter pool 102 filters the insoluble impurities and suspended solids in the sewage, and the suspended solids content in the sewage treated by the filter pool 102 is within the range of [40, 50] mg / L; oxygenation The poo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com