3D house printing machine

A technology of printers and houses, applied in the field of 3D house printers, can solve the problems of unable to fundamentally solve the problems of house automation construction and poor house bearing capacity, and achieve the effects of increasing speed, reliable operation and improving automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the technical solution of this embodiment will be described in detail below in conjunction with the accompanying drawings. The following embodiments are only used to illustrate the technical solution of this embodiment more clearly, so they are only examples, and should not be used to limit the protection scope of this embodiment.

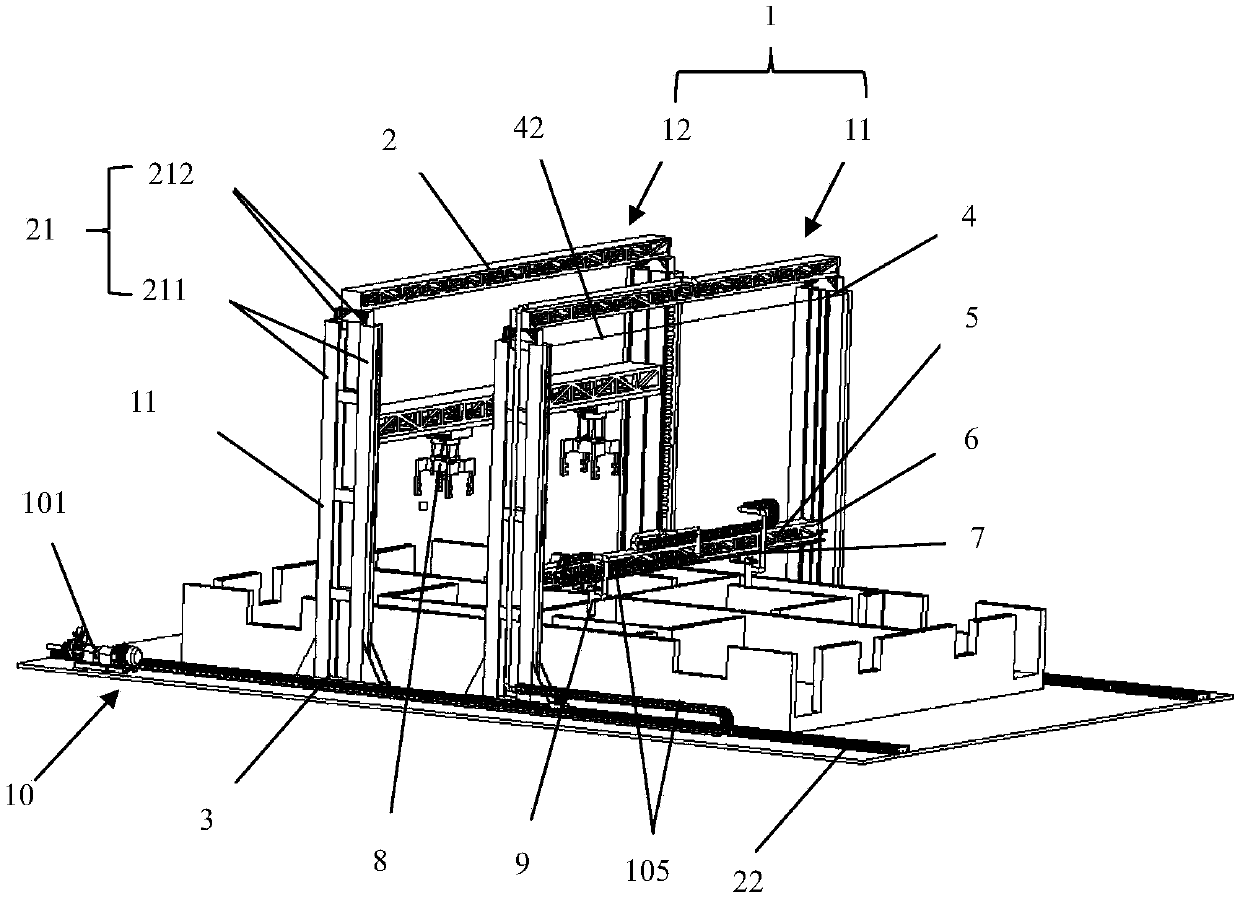

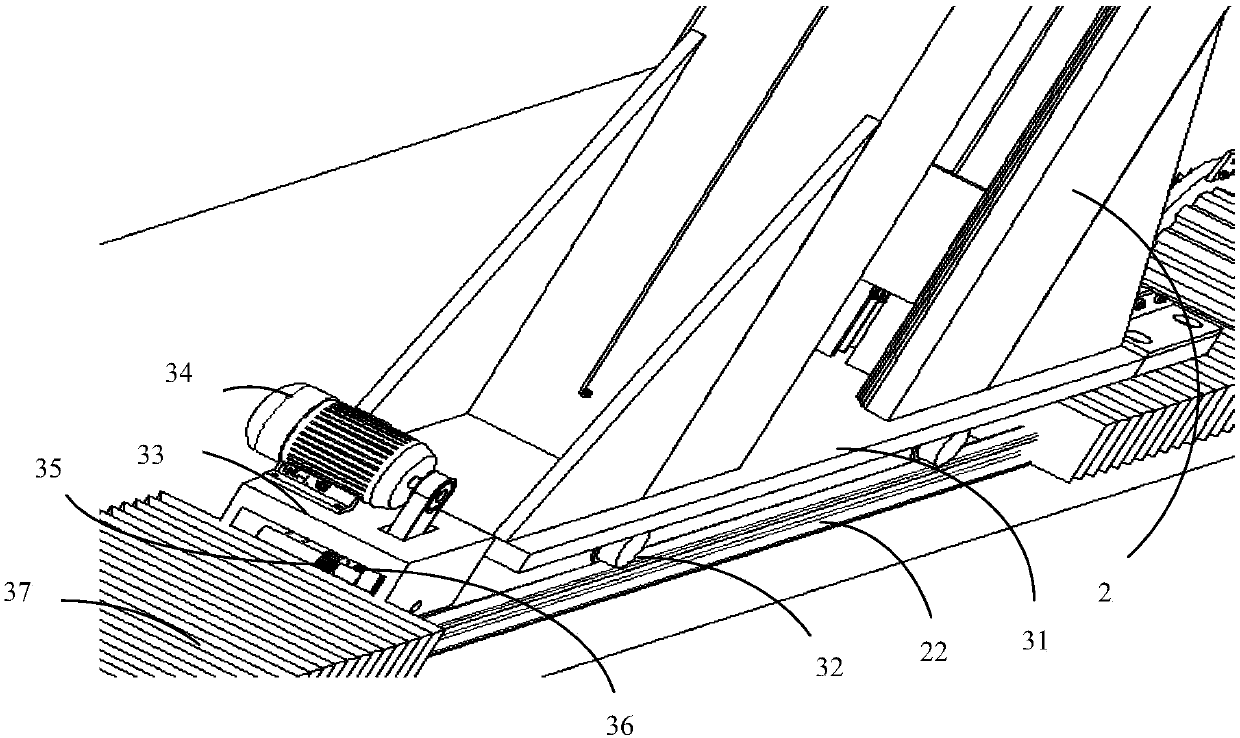

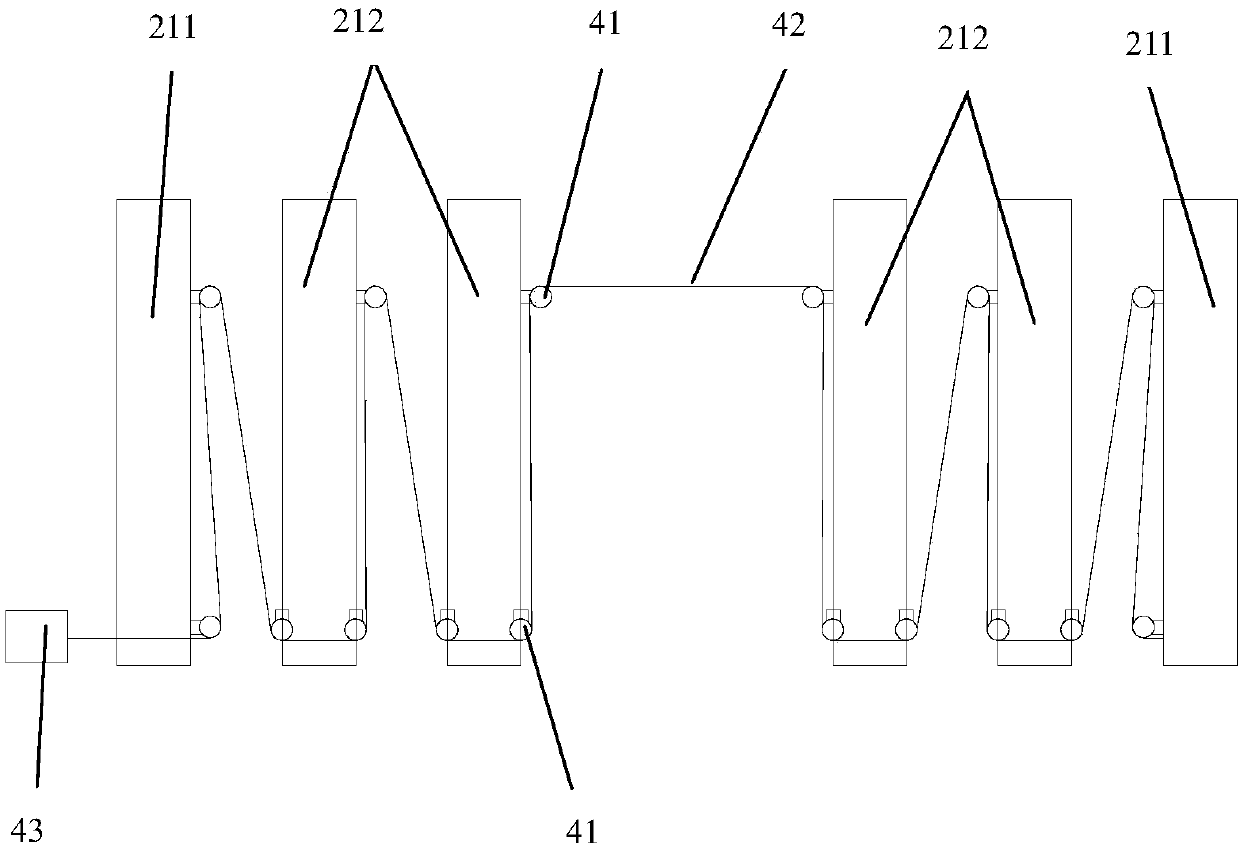

[0027] Such as Figure 1-Figure 8As shown, the embodiment of the present invention provides a 3D house printer, including a truss assembly 1, a manipulator 8, a discharge port 9 and a feeding mechanism 10, the truss assembly 1 is provided with two groups of manipulator truss assemblies 11 and printer truss assemblies 12, Each set of truss components 1 includes a truss 2, a truss walking mechanism 3, a truss lifting mechanism 4, a lifting beam 5, and a beam lifting mechanism 6. Telescopic brackets 21 are arranged on both sides of the truss 2, and the truss 2 passes through the telescopic brackets on both sides. 21 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com