Mechanical maintenance tool box

A technology for maintenance tools and machinery, applied in the direction of manufacturing tools, tool storage devices, etc., can solve the problems of wasting manpower and time costs of staff, the weight of mechanical maintenance tools is not light, reducing work efficiency, etc. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

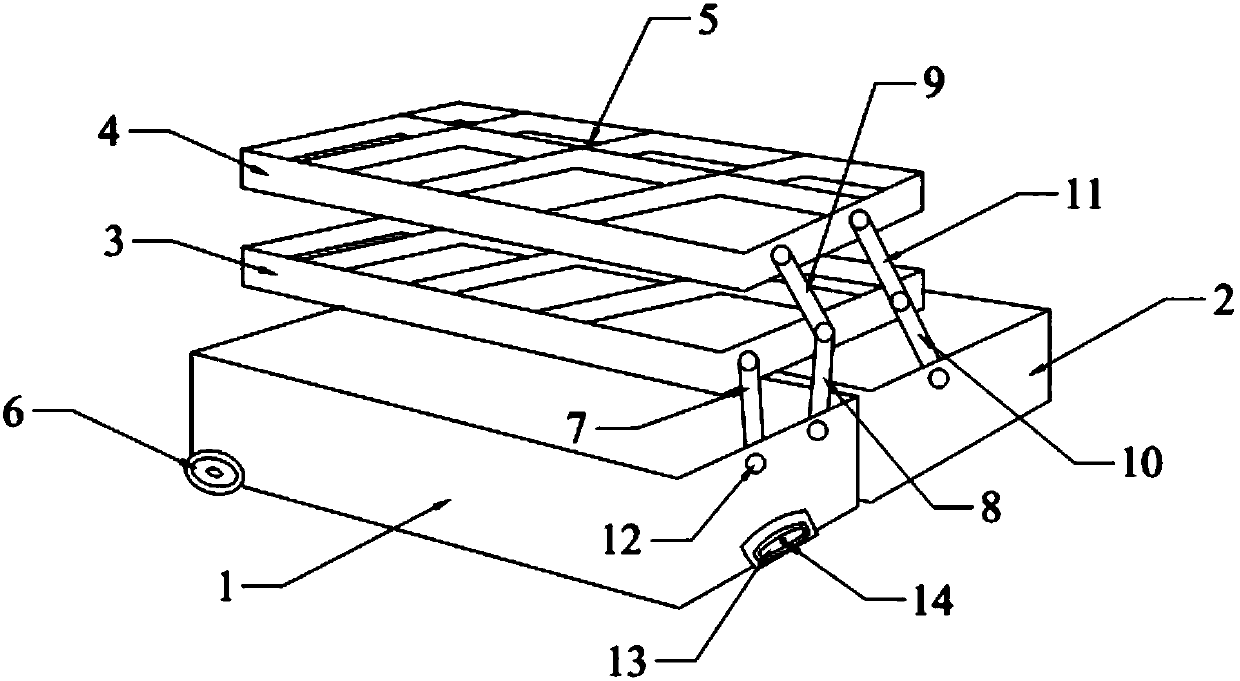

[0015] Such as figure 1 Shown: a mechanical maintenance toolbox, its structure includes: box body 1, box cover 2, first-level inner layer 3, second-level inner layer 4, tool slot 5, roller 6, first connecting rod 7, second connecting rod Rod 8, third connecting rod 9, fixed column 10, handle 11; both the box body 1 and the box cover 2 are U-shaped groove structure design, and one end of the first connecting rod 7 is fixed on the first-level inner layer 3 side On the fixed column 10 of the facade, the other end is connected with the side elevation of the box body 1 through the fixed column 10, the upper end of the second connecting rod 8 is connected with the secondary inner layer 4 through the fixed column 10, and the middle part is connected with a The inner layer 3 of the second level is connected through the fixed column 10, the bottom and the box body 1 are connected through the fixed column 10, the upper end of the third connecting rod 9 is connected with the inner layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com