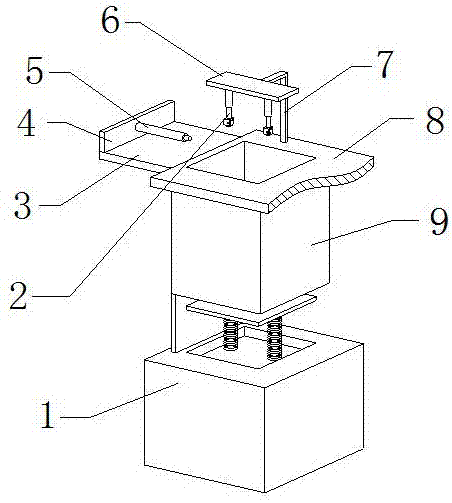

Online feeding mechanism based on industrial machines

A technology of feeding mechanism and industrial machinery, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of inability to provide stable feeding pushing force, cost waste, and easily scratched materials, etc., to improve the protection effect, reduce wear, and avoid Effects of damaged materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

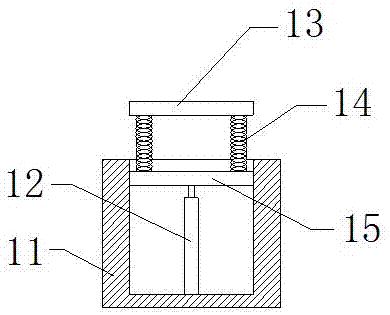

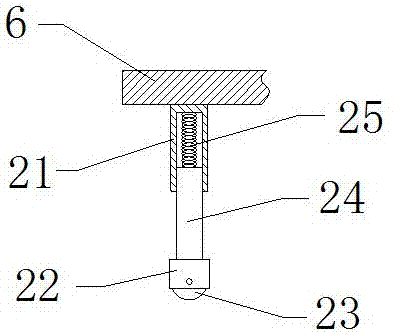

[0023] Specific implementation method: when using, at first the staff assembles the material in the storage barrel 9, and then the material squeezes the push plate 13, and the push plate 13 squeezes the spring one 14, forcing the spring one 14 to undergo elastic deformation. After the material in the barrel 9 is full, the material squeezes the roller 23, and then the roller 23 pushes the telescopic rod 24 to move upward through the roller seat 22, and then the telescopic rod 24 squeezes the spring 225, forcing the spring 25 to undergo elastic deformation, thereby achieving the buffering effect. Purpose, when the staff runs the pneumatic cylinder 5, the pneumatic cylinder 5 drives the rubber disc to move, and then the rubber disc pushes the material exposed on the feeding platform 8, so as to achieve the purpose of feeding. During the movement of the material, the material drives the roller 23 on the roller Rotate inside the seat 22, thereby avoiding the situation of scratching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com