Painting and leveling device

A technology for painting and adjusting devices, which is applied to the device for coating liquid on the surface, pre-treating the surface, coating, etc. It can solve the problems of not controlling the time of painting, being unable to use, increasing costs, etc., and achieving Reduce paint drying time, reduce invalid products, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

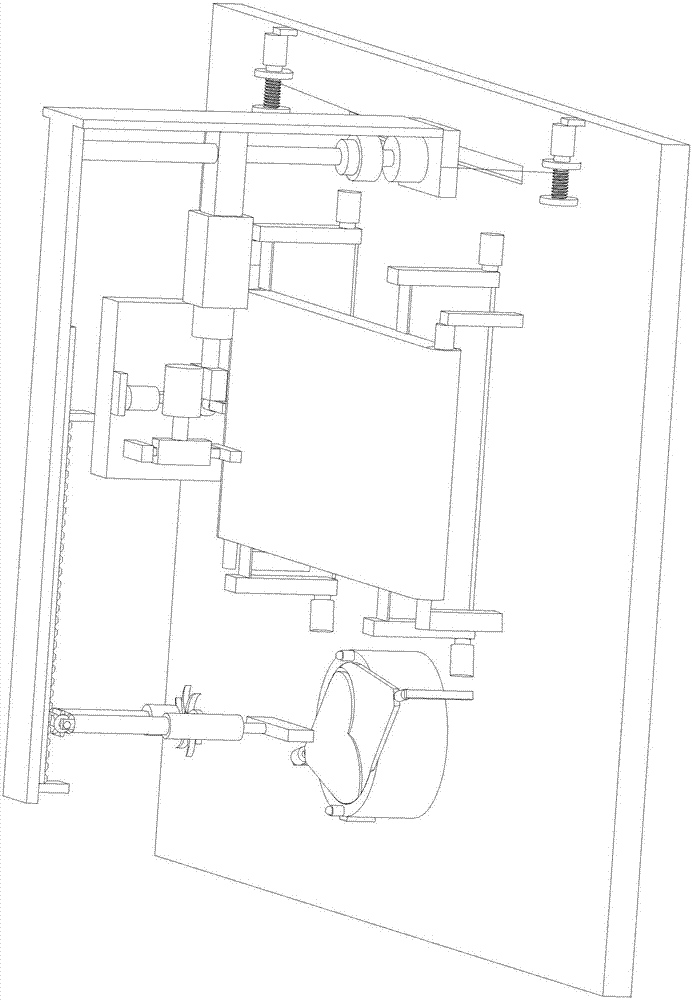

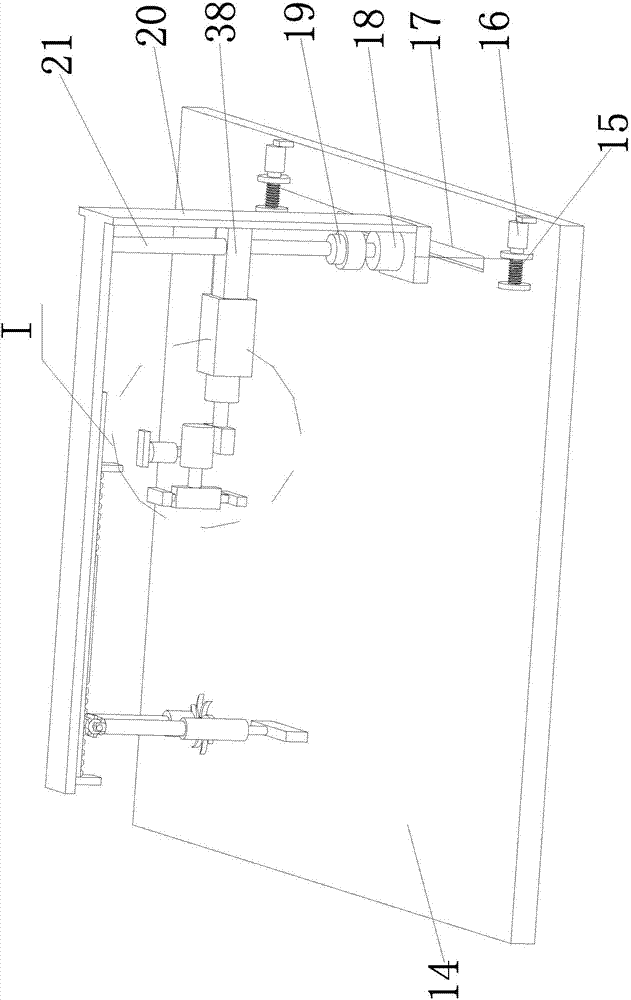

[0026] Such as Figure 1 to Figure 8 As shown, a paint troweling device includes a base plate 14, a position adjustment device that can produce relative sliding is installed on one end of the base plate 14, and a paint brushing mechanism is connected to the position adjustment device. An induction paint bucket mechanism is installed on the other end of the bottom plate 14, a conveying mechanism is arranged between the induction paint bucket mechanism and the position adjustment device, and two clamping mechanisms are arranged on both sides of the conveying mechanism. A turning device is provided at the end.

[0027] The position adjusting device is mainly to adjust the position relative to the workpiece; the paint brushing mechanism is mainly to paint the workpiece; the induction paint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com