Power box for reciprocating drilling mud pump

A drilling mud, reciprocating technology, which is applied to the parts of the pumping device for elastic fluid, the parts of the variable displacement pump, the pump, etc., can solve the problems of increased pump power, large volume of the reducer, and difficulty in seating. , to achieve the effect of reducing the combined volume, reducing the volume and weight, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

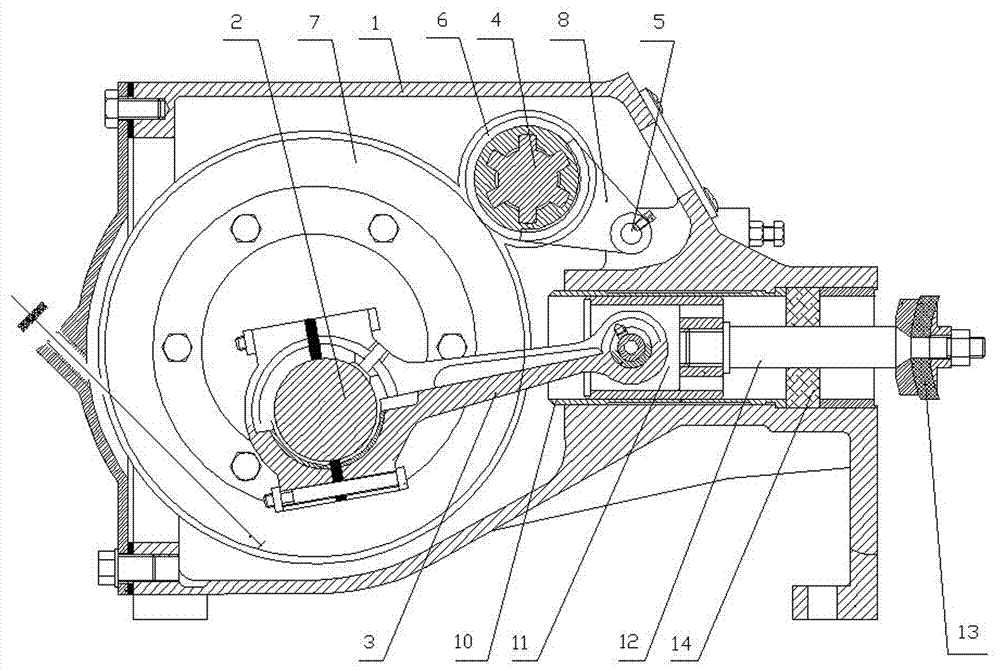

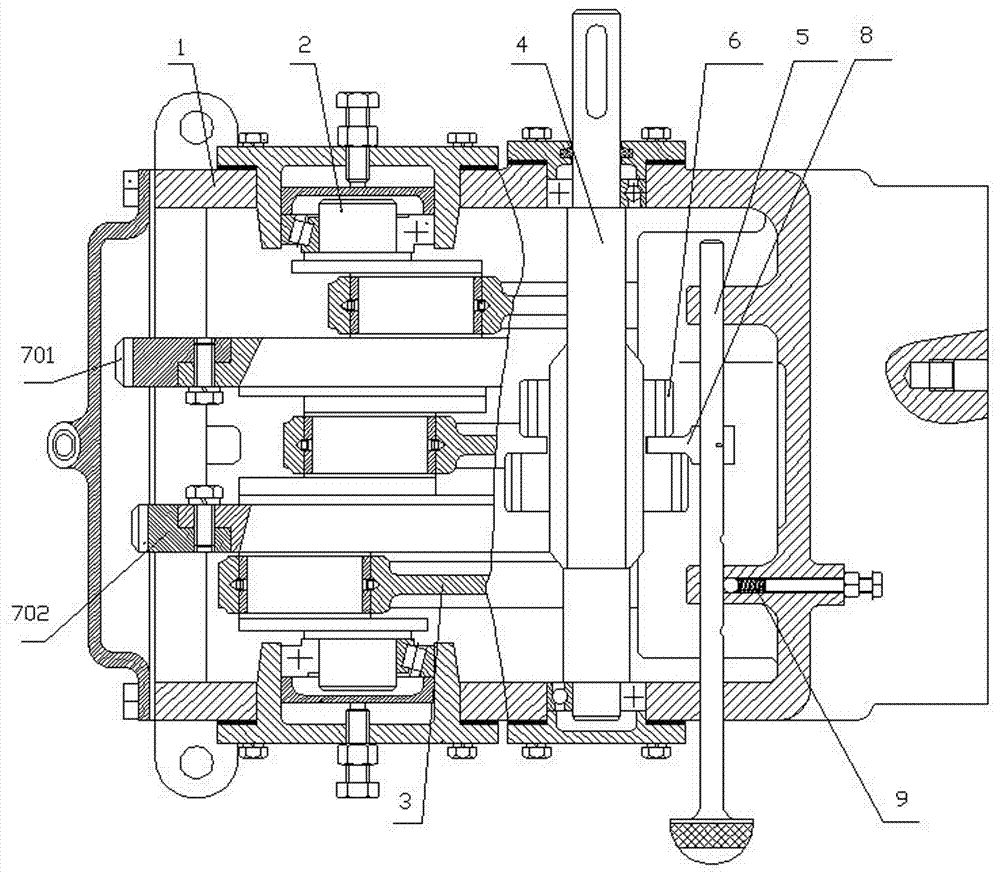

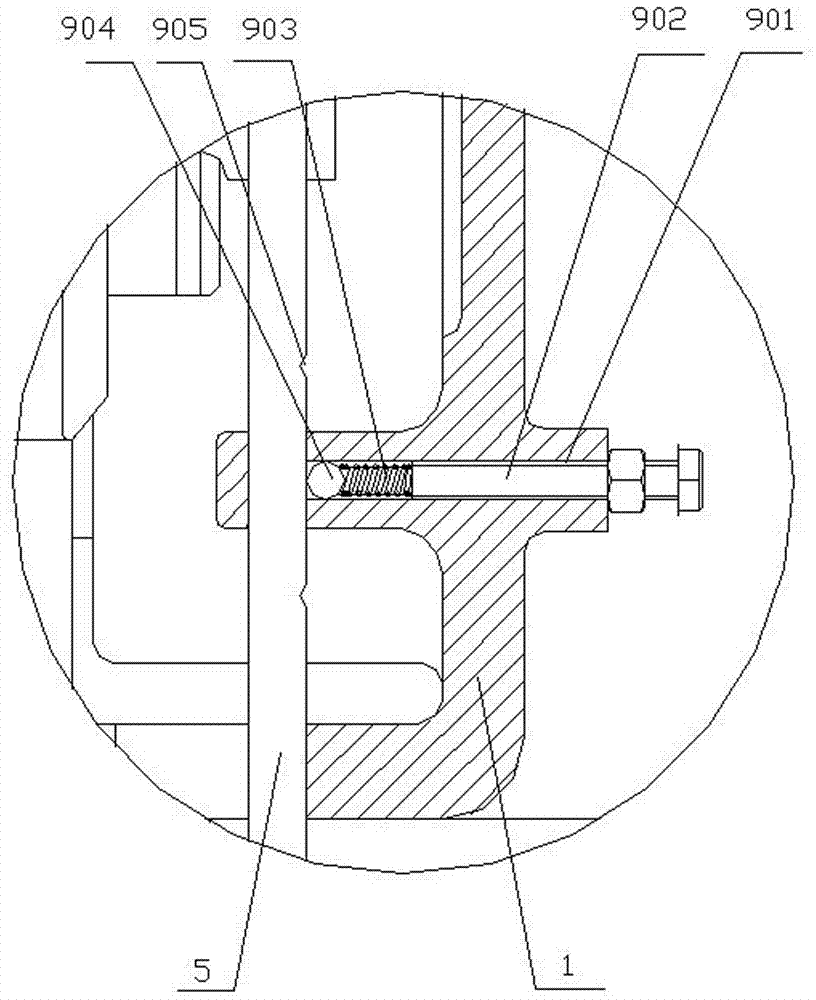

[0020] Such as Figure 1 to Figure 3 As shown, a power box for a reciprocating drilling mud pump of the present invention includes a box body 1, a crankshaft 2 is rotated in the box body 1, and a connecting rod 3 is installed on the crankshaft 2, and a box body 1 is provided with There is a sliding sleeve 10 corresponding to the connecting rod 3. A crosshead slider 11 is slid inside the sliding sleeve 10. One end of the crosshead slider 11 is hinged with the connecting rod 3, and the other end is fixed with a piston rod 12. The piston rod 12 is far away from the One end of the crosshead slider 11 is connected with a piston sleeve 13 . The piston rod 12 is covered with a mud scraper 14, and the outer edge of the mud scraper 14 is fixedly connected with the inner wall of the sliding sleeve 10. The mud scraper 14 can scrape off the oil stain on the piston rod 12 during the reciprocating movement of the piston rod 12. Avoid clogging.

[0021] During the implementation of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com