Method for preparing graphene photocurable resin nanomaterial, casting solution and casting method

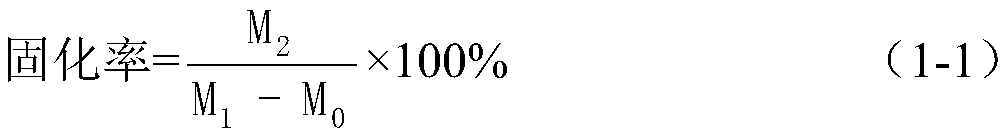

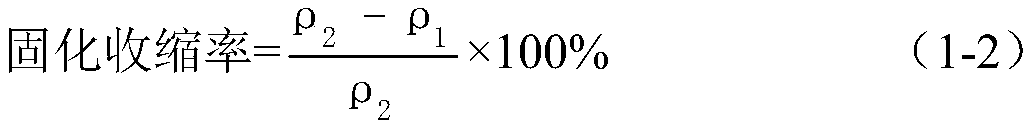

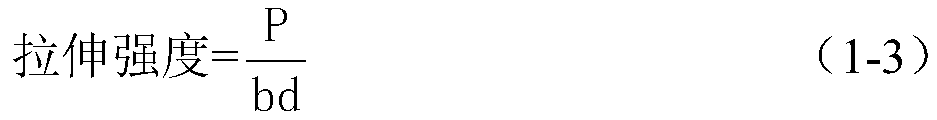

A light-curing resin and nano-material technology, applied in the direction of additive processing, etc., can solve the problems of poor mechanical properties, insufficient toughness, high printing cost, etc., to improve tensile properties and bending properties, wide application range, and reduce volume shrinkage rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Graphene photocurable resin nanomaterials include graphene oxide and photosensitive resin, and the preparation method of described graphene oxide is as follows:

[0028] (1) Preparation of graphene oxide

[0029] Add 3.0g of flake graphite and 1.5g of sodium nitrate into 69mL of concentrated sulfuric acid, oscillate ultrasonically for 20min in an ice bath, slowly add 18.0g of potassium permanganate, ultrasonicate for 5min below 20°C, and stir for 2h in a water bath at 35-40°C. Then transfer it to a constant temperature water bath at 90°C and stir for 30 minutes, cool to room temperature, add 400mL of ice water and stir to mix, then slowly add 3mL of 30% hydrogen peroxide and stir for 2h, filter, and successively wash with distilled water, 30% hydrochloric acid and ethanol Wash repeatedly, and centrifuge at 6000r / min for 10min to remove larger solids. Finally, the suspension is filtered with PTEE membrane, and the obtained solid is vacuum-dried at room temperature for 12...

Embodiment 2

[0033] Graphene photocurable resin nanomaterials include graphene oxide and photosensitive resin, and the preparation method of described graphene oxide is as follows:

[0034] (1) Preparation of graphene oxide

[0035] Add 3.0g flake graphite and 1g sodium nitrate into 68mL concentrated sulfuric acid, oscillate ultrasonically for 15min in an ice bath, slowly add 10g potassium permanganate, ultrasonicate for 8min below 20°C, stir for 2h in a water bath at 35-40°C, then Transfer it to a constant temperature water bath at 90°C and stir for 40 minutes, cool to room temperature, add 400 mL of ice water and stir to mix, then slowly add 3 mL of 30% hydrogen peroxide and stir for 2 hours, filter, and repeat with distilled water, 30% hydrochloric acid and ethanol in turn. Wash and centrifuge at a speed of 6000r / min for 10min to remove larger solids, and finally filter the suspension with a PTEE membrane, and dry the solid under vacuum at room temperature for 12h to obtain brown graphi...

Embodiment 3

[0039] Graphene photocurable resin nanomaterials include graphene oxide and photosensitive resin, and the preparation method of described graphene oxide is as follows:

[0040] (1) Preparation of graphene oxide

[0041]Add 3.0g of flake graphite and 3.0g of sodium nitrate into 75mL of concentrated sulfuric acid, oscillate ultrasonically for 15min in an ice bath, slowly add 40g of potassium permanganate, ultrasonicate for 8min below 20°C, and stir for 2h in a water bath at 35-40°C. Then transfer it to a constant temperature water bath at 90°C and stir for 40 minutes, cool to room temperature, add 800 mL of ice water and stir to mix, then slowly add 3 mL of 30% hydrogen peroxide and stir for 2 hours, filter, and repeat with distilled water, 30% hydrochloric acid and ethanol in sequence Wash and centrifuge at a speed of 6000r / min for 10min to remove larger solids. Finally, the suspension is filtered with a 0.25um PTEE membrane, and the resulting solid is vacuum-dried for 12h at r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com