A scheduling method and device for installation and maintenance work orders

A scheduling method and work order technology, applied in the directions of instruments, data processing applications, resources, etc., can solve the problems of inability to guarantee the completion rate of work orders and low scheduling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

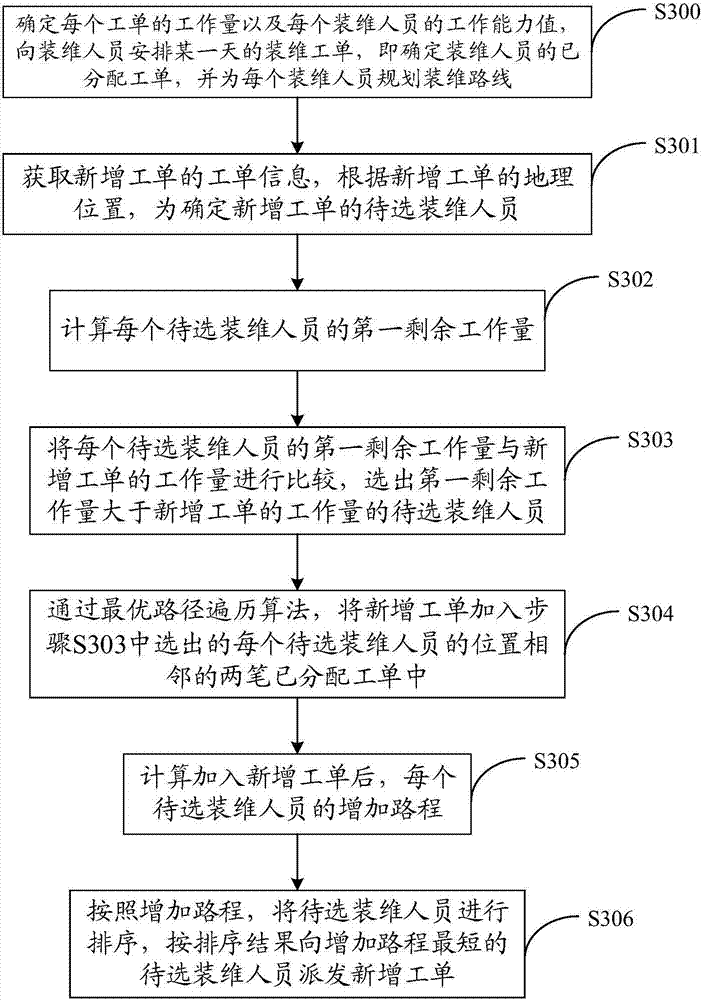

[0101] The concrete steps of embodiment two are as Figure 4 shown, including:

[0102] S400. Determine the workload of each work order and the work capacity value of each installation and maintenance personnel, arrange an installation and maintenance work order for a certain day to the installation and maintenance personnel, that is, determine the assigned work orders of the installation and maintenance personnel, and provide Maintenance personnel plan installation and maintenance routes.

[0103] S401. Acquire the work order information of the newly added work order, and determine the installation and maintenance personnel to be selected for the newly added work order according to the geographic location of the newly added work order.

[0104] S402. Calculate the first remaining workload of each installation and maintenance personnel to be selected.

[0105] S403. Comparing the first remaining workload of each installation and maintenance personnel to be selected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com