Precise locating and fixing device of prefabricated part embedded parts and using method of locating and fixing device

A technology for precise positioning and prefabrication of components, applied in building construction, building material processing, construction, etc., can solve problems such as the inability to guarantee position accuracy, achieve good demoulding effect, ensure accurate positioning and fixation, and simple and practical installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

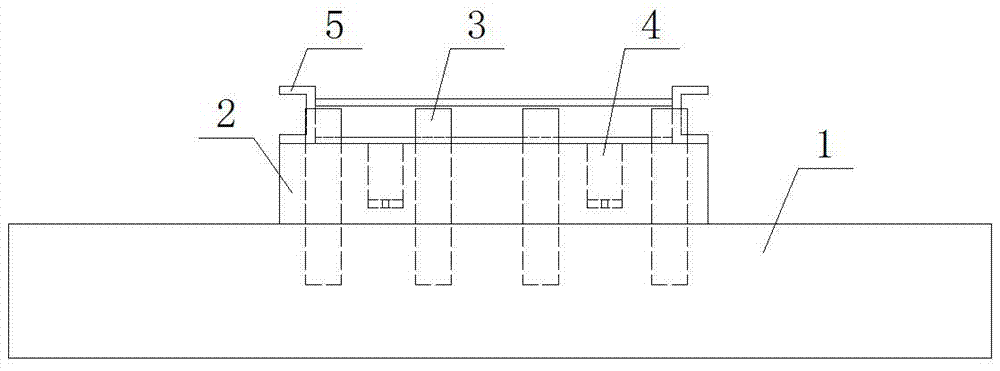

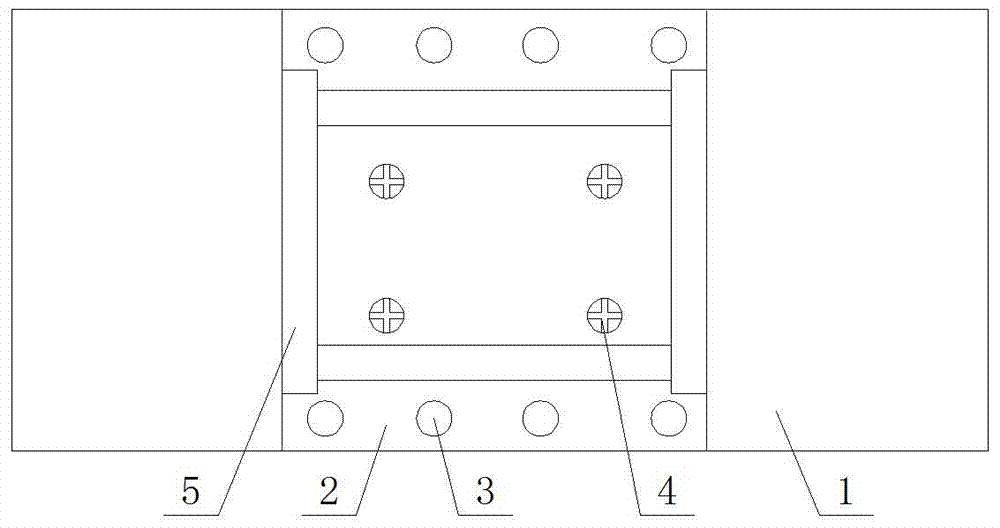

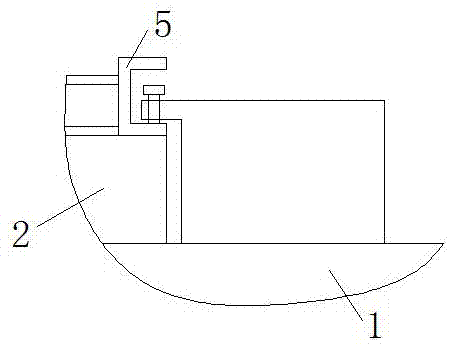

[0027] Such as figure 1 and 2 As shown, a prefabricated component embedded parts precise positioning and fixing device includes a steel bottom mold 1, an aluminum top mold 2 is provided on the steel bottom mold 1, and a number of embedded parts are positioned on the aluminum top mold 2. Hole 4, the positioning pin of the embedded part is inserted into the positioning hole of the embedded part, the positioning pin of the embedded part is connected with the embedded part, and the aluminum material top mold 2 is provided with an aluminum side mold 5.

[0028] During construction, the aluminum top mold is fixed on the steel bottom mold, one end of the positioning pin of the embedded part is inserted into the positioning hole, and the other end of the positioning pin of the embedded part is connected with the embedded part to realize the accurate and precise positioning of the embedded part. Concrete is poured in the pouring area surrounded by the aluminum side formwork, and the p...

Embodiment 2

[0031] A precise positioning and fixing device for embedded parts of prefabricated components, the steel bottom mold 1 is provided with bottom mold positioning holes in the long side direction, the aluminum material top mold 2 is provided with top mold positioning pins 3 in the long side direction, and the aluminum The material top mold 2 is inserted into the bottom mold positioning hole by the top mold positioning pin 3 and is connected with the steel bottom mold 1.

[0032] Other structures are with embodiment 1.

[0033] The width of the steel bottom mold and the aluminum top mold is the same, and the length of the aluminum top mold is slightly longer than the length of the prefabricated component, so that the aluminum side mold can be set on the aluminum top mold, and the positioning pin of the top mold runs through the aluminum top mold and inserts The positioning hole of the bottom mold realizes the fixation between the aluminum top mold and the steel bottom mold to ensu...

Embodiment 3

[0035] A precise positioning and fixing device for embedded parts of prefabricated components, the lower part of the embedded part positioning hole 4 is provided with a cross-shaped groove, the lower part of the embedded part positioning pin is provided with a cross-shaped pin cap, and the pin cap is embedded in the concave In the groove, the upper part of the positioning pin of the embedded part is provided with threads, and the positioning pin of the embedded part is threadedly connected with the embedded part.

[0036] Other structures are with embodiment 1.

[0037] The thickness of the aluminum top mold is slightly larger than the depth of the positioning hole of the embedded part. The pin cap of the positioning pin of the embedded part is embedded in the groove, which can prevent the positioning pin of the embedded part from rotating. The upper part of the positioning pin of the embedded part and the embedded part Threaded connection realizes the fixing of the embedded p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com