Aircraft wall panel digitalization processing and assembling system

An aircraft wall panel and assembly system technology, applied in aircraft assembly, aircraft parts, transportation and packaging, etc., can solve the problems of multiple hoisting, low production efficiency, long procurement cycle, etc., to improve processing efficiency and high functional integration. , The effect of convenient manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

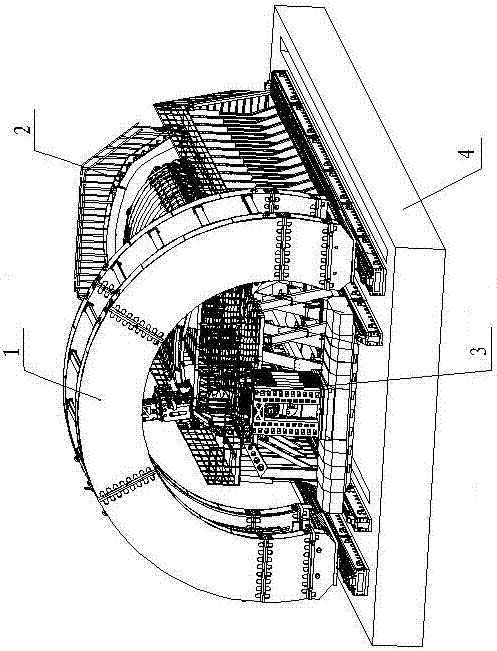

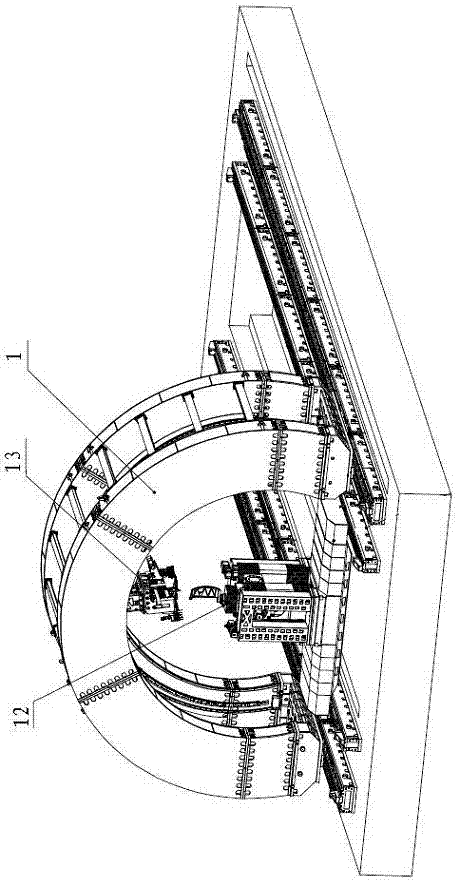

[0017] The aircraft panel digital processing assembly system of the present invention, such as figure 1 As shown, the hole-making and riveting system of the lower wall is composed of three parts: the skin side execution system, the stringer side execution system and the positioning tooling.

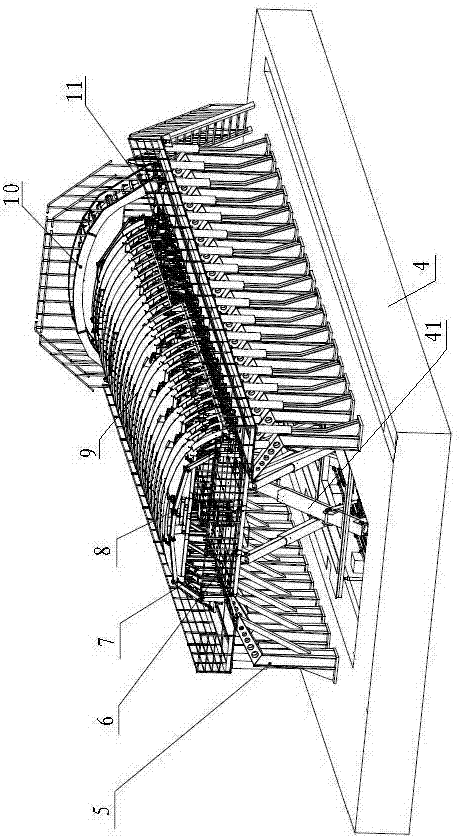

[0018] The tooling part of the hole making and pressing riveting system of the lower wall plate is as follows: figure 2 As shown, it is mainly composed of a tooling platform 5, a lifting platform 6, a frame positioning component 7, a skin positioning component 8, a multifunctional working ladder 10, and a skin tensioning component 11. The skin positioning tooling 2 includes a tooling platform 5, a lifting platform 6. The frame positioning assembly 7 and the frame 9, the tooling platforms 5 on both sides are installed on the ground 4, the two ends of each frame 9 are installed on the tooling platforms 5 on both sides through the frame positioning assembly 7, the frame 9 is arc-shaped, fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com