Material transfer vehicle

A turnover car and material technology, applied in the direction of motor vehicles, trolleys, multi-axis trolleys, etc., can solve the problems of incompatibility with products of different lengths, automatic adjustment, etc., and achieve the effect of avoiding mixing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

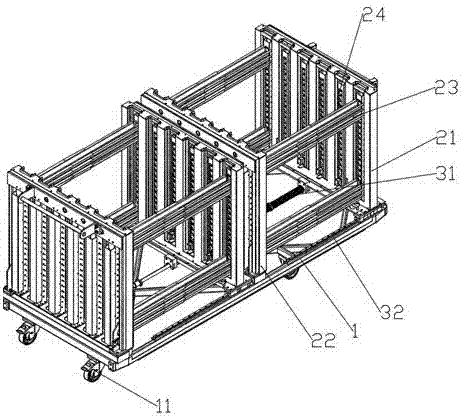

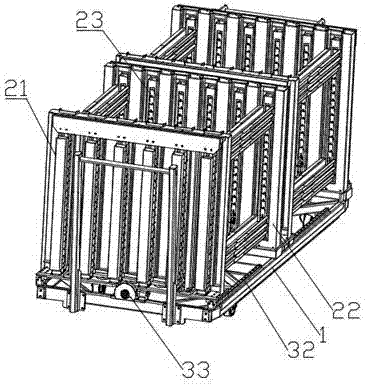

[0024] see figure 1 with figure 2 , a material turnover vehicle, including a base 1, a material storage mechanism and a track drive mechanism, four universal wheels 11 are installed under the base 1, and each universal wheel 11 is provided with a brake device.

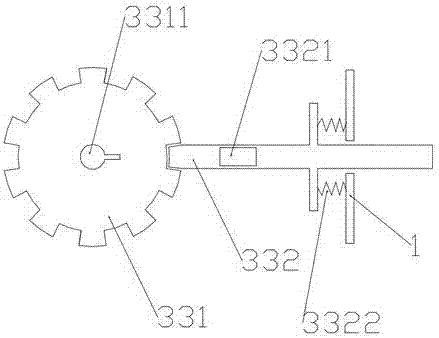

[0025] see figure 1 with figure 2 , the storage mechanism includes a movable baffle 21, a fixed baffle 22, a side bar 23 and a bracket 2, and the track drive mechanism includes a screw 31, a guide rail 32 and an adjustment mechanism 33; the screw 31 and the guide rail 32 are installed on the base 1 , two guide rails 32 are installed on both sides of screw rod 31 parallel to screw rod 31; The baffle plate 22 is relatively installed on the screw rod 31 and the guide rail 32. A fixed baffle plate 22 and a movable baffle plate 21 form a group, that is, there are two groups, and the fixed baffle plate 22 and the movable baffle plate 21 of each group correspond to both sides. They are respectively connected by adjustab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com