Kitchen waste crushing device capable of realizing solid-liquid separation function

A technology of kitchen waste and crushing device, which is applied in the direction of filtration and separation, separation method, fixed filter element filter, etc., can solve the problems of easy generation of biogas, easy corruption, safety problems, etc., achieve efficient crushing treatment, and reduce noise pollution , the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

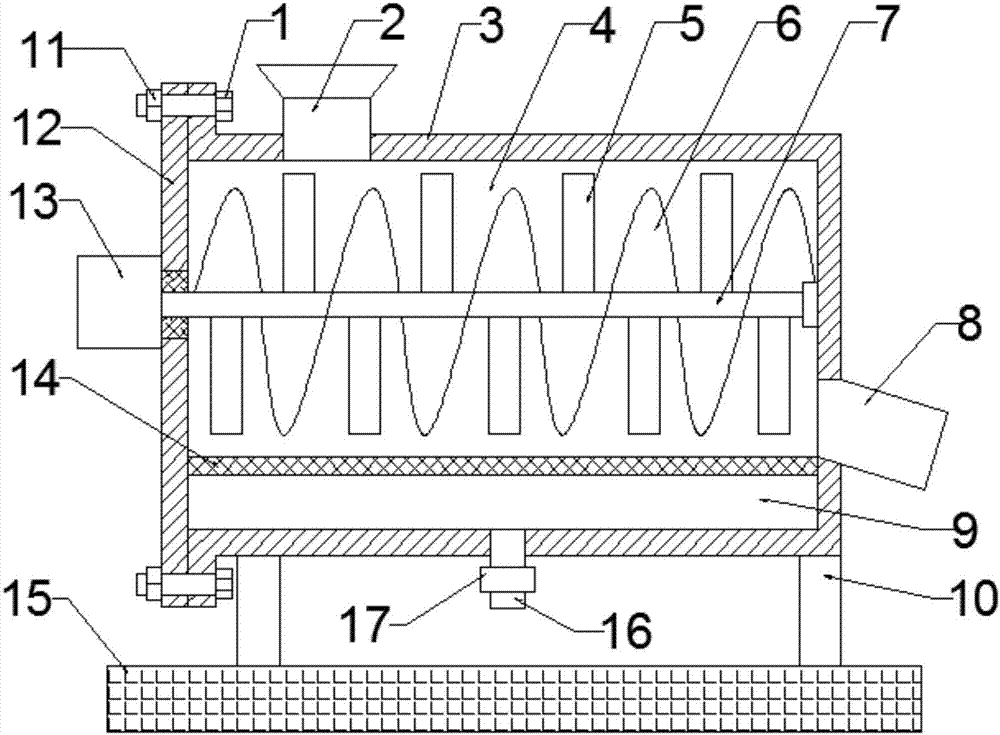

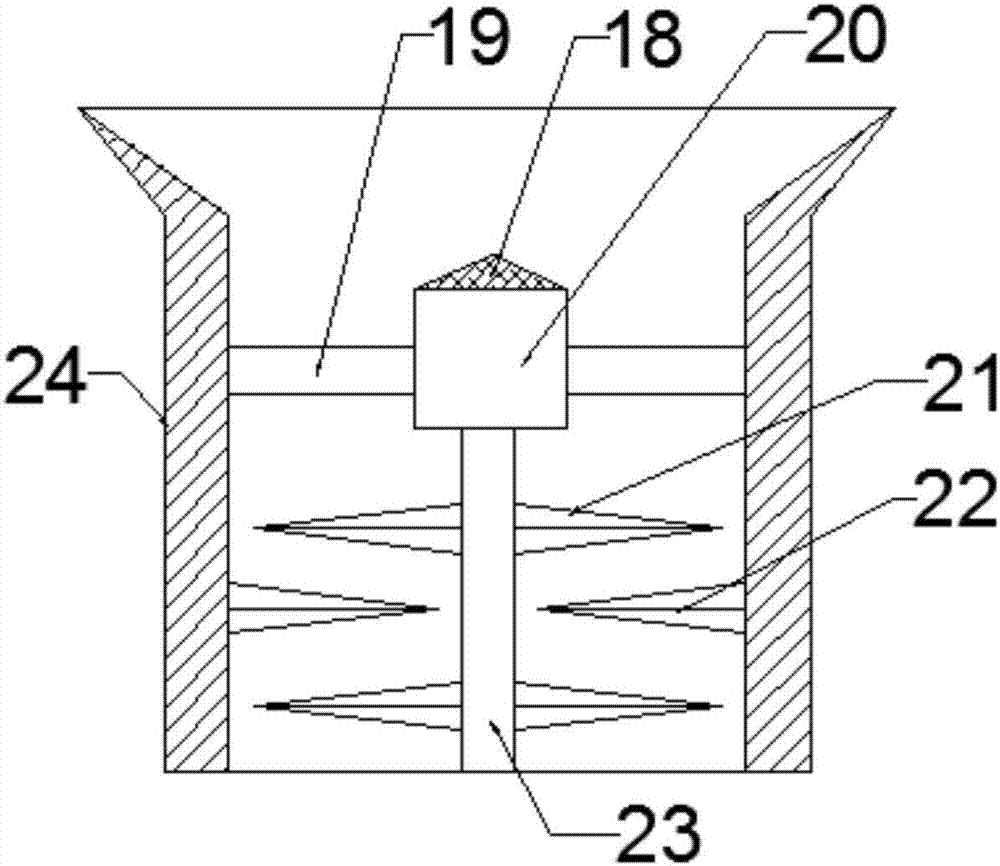

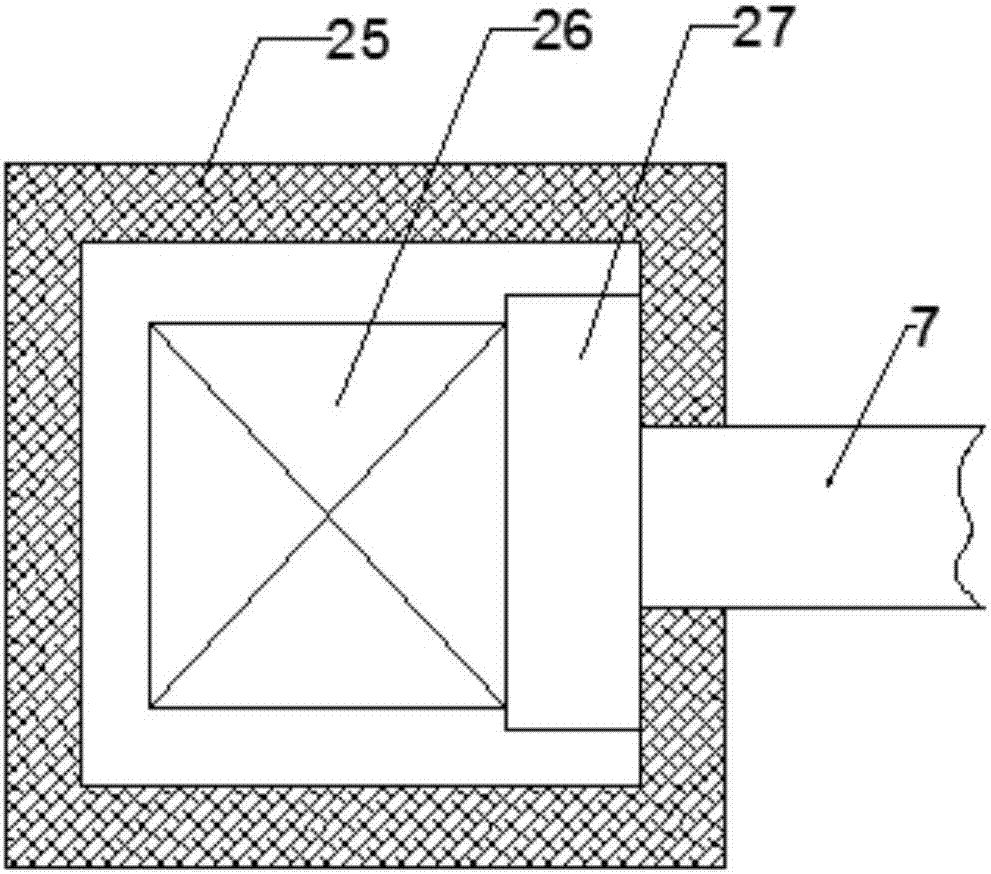

[0016] see figure 1 , this embodiment provides a kitchen waste crushing device capable of solid-liquid separation, including a housing 3, a crushing rod 5, a discharge port 8, a cover plate 12, a base 15 and a drain pipe 16; the housing 3 Horizontally arranged above the base 15, the inside of the housing 3 is provided with a crushing chamber 4 and a sewage chamber 9; the base 15 is arranged directly below the housing 3, and the housing 3 is fixedly connected to the base 15 through the support column 10; the housing 3 The top is provided with a feeding device 2, and the left end is provided with a cover plate 12; the cover plate 12 is fixedly connected to the left end of the housing 3 by screwing bolts 1 and nuts 11, and a transmission device is provided on the left center line of the cover plate 12 13. The crushing chamber 4 is provided with a cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com