Anti-chapped hand cream and production process

A production process and technology of hand cream, applied in the direction of skin care preparations, cosmetics, cosmetic preparations, etc., to achieve the effects of resisting external stimuli, facilitating promotion, and relieving pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Please refer to figure 1 As shown, the present invention provides a kind of scheme: a kind of anti-chapped hand cream and production process, the production process of described anti-chapped hand cream is as follows:

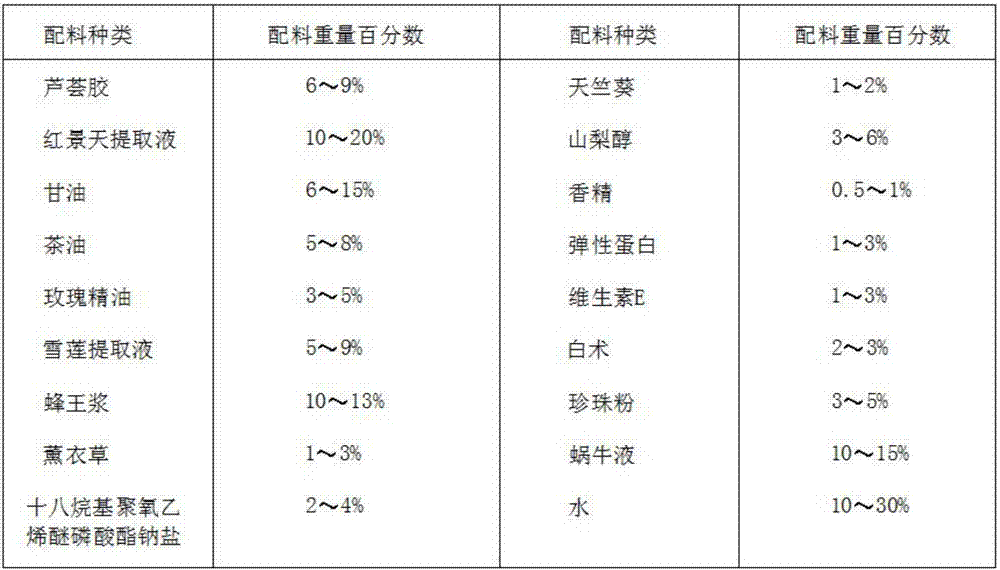

[0023] 1) Divide each raw material into the following two groups:

[0024] Group 1 includes: aloe vera gel 6%; rhodiola rosea extract 10%; glycerin 6%; snow lotus extract 5%; royal jelly 10%; sorbitol 3%; ;Water 30%;

[0025] Group 2 includes: tea oil 5%; rose essential oil 3%; lavender 1%; geranium 1%; elastin 1%; vitamin E 1%;

[0026] 2) Mix all the components of Group 1 according to the ratio and add to the water phase pot, heat up to 60°C, stir in the emulsified water phase pot with a magnetic stirrer at a stirring rate of 800r / min, disperse evenly, and react for 15 minutes;

[0027] 3) Mix all the components of group 2 according to the ratio and add them to the oil phase pot, raise the temperature to 60°C, stir in the emulsified oil phase pot wit...

Embodiment 2

[0030] Please refer to figure 1 As shown, the present invention provides a kind of scheme: a kind of anti-chapped hand cream and production process, the production process of described anti-chapped hand cream is as follows:

[0031] 1) Divide each raw material into the following two groups:

[0032] Group 1 includes: aloe vera gel 9%; rhodiola rosea extract 15%; glycerin 6%; snow lotus extract 5%; royal jelly 10%; sorbitol 3%; ;Water 20%;

[0033] Group 2 includes: tea oil 5%; rose essential oil 3%; lavender 1%; geranium 1%; elastin 1%; vitamin E 1%;

[0034] 2) Mix all the components of Group 1 according to the ratio and add to the water phase pot, heat up to 80°C, stir in the emulsified water phase pot with a magnetic stirrer at a stirring rate of 300r / min, disperse evenly, and react for 15 minutes;

[0035] 3) Mix all the components of Group 2 according to the ratio and add them to the oil phase pot, raise the temperature to 80°C, stir in the emulsified oil phase pot wit...

Embodiment 3

[0038] Please refer to figure 1 As shown, the present invention provides a kind of scheme: a kind of anti-chapped hand cream and production process, the production process of described anti-chapped hand cream is as follows:

[0039] 1) Divide each raw material into the following two groups:

[0040] Group 1 includes: aloe vera gel 6%; rhodiola rosea extract 10%; glycerin 10%; snow lotus extract 9%; royal jelly 12%; sorbitol 3%; ;Water 20%;

[0041] Group 2 includes: tea oil 5%; rose essential oil 3%; lavender 1%; geranium 1%; elastin 1%; vitamin E 1%;

[0042] 2) Mix all the components of Group 1 according to the ratio and add to the water phase pot, raise the temperature to 70°C, stir in the emulsified water phase pot with a magnetic stirrer at a stirring rate of 500r / min, disperse evenly, and react for 10 minutes;

[0043] 3) Mix all the components of group 2 according to the ratio and add them to the oil phase pot, raise the temperature to 70°C, stir in the emulsified oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com