Internet of things intelligent hog house control system

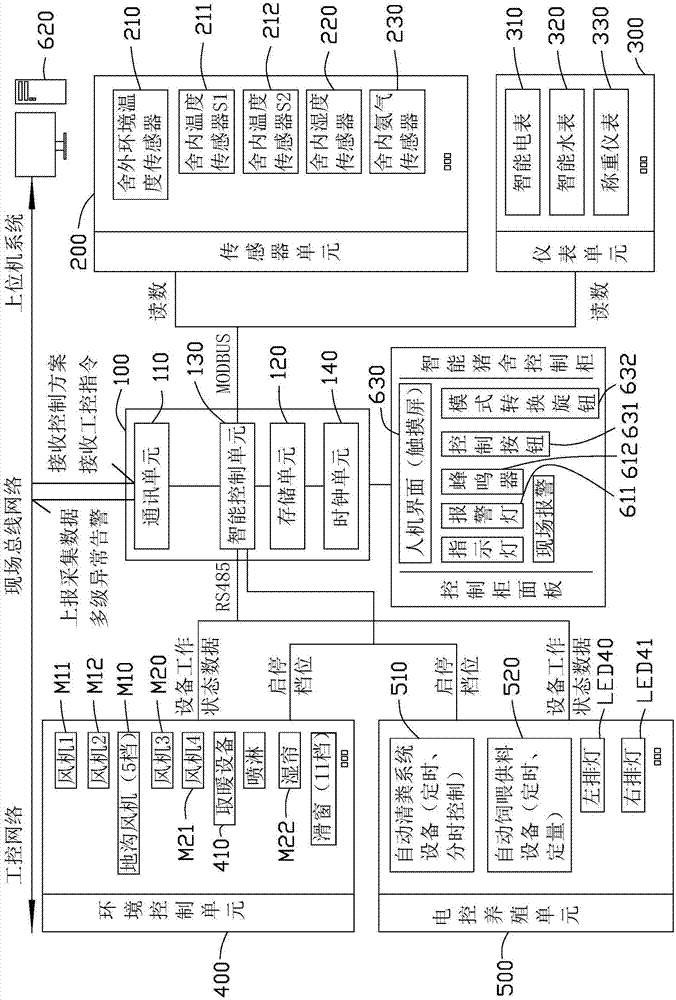

A technology of control system and Internet of Things, applied in the direction of control/adjustment system, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problem of difficult recruitment, need for labor, and centralized and unified management of pig house environment control equipment and breeding equipment And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

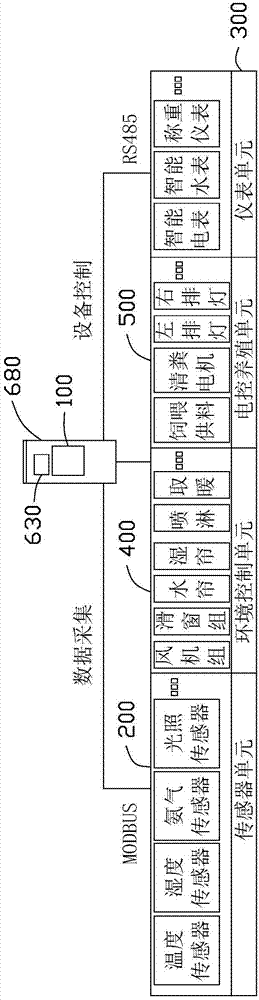

Method used

Image

Examples

example 2

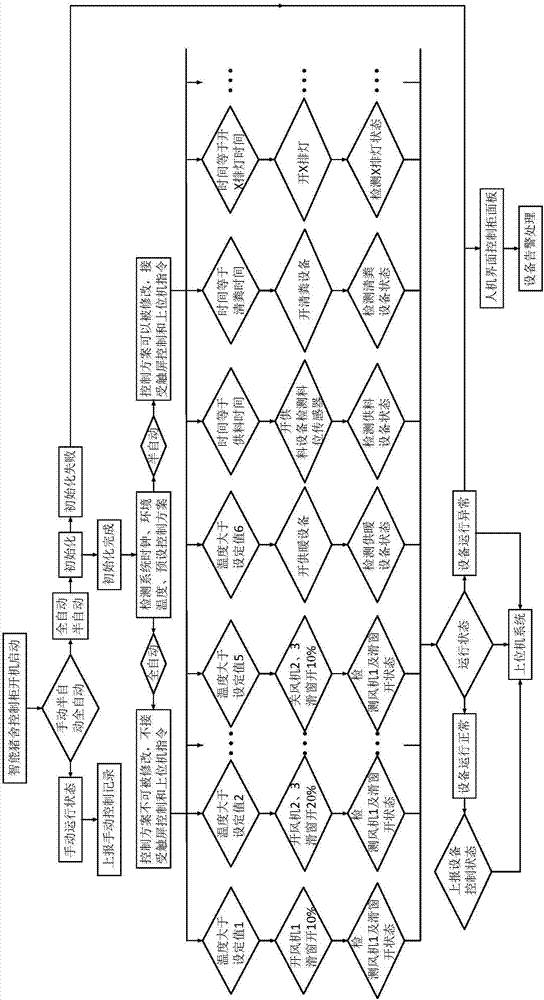

[0070] The following is an implementation example of the scheme for automatic temperature adjustment of the environmental control equipment in the pig house:

[0071] At present, all pigs in the pig house are fattening stage pigs, and the optimum growth temperature is 26°C. Therefore, the ambient temperature control target inside the pig house should be 26°C as the standard.

[0072] When the outside temperature is 25°C, due to the large number of pigs in the house, the temperature inside the house is 30°C.

[0073] When the preset value of the environmental control scheme is in the range of 28°C--31°C:

[0074] Fan 1 (M11) ON

[0075] Fan 2 (M12) ON

[0076] Fan 4 (M21) ON

[0077] Trench fan on 2 gears

[0078] Sliding window open 30%

[0079] Cooling wet curtain alternately open for 30 minutes and close for 30 minutes

[0080] Others are all closed

[0081] At this time, when the programmable logic controller U detects that the current temperature in the pig house is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com