High-temperature and high-pressure top-assembled ball valve

A high-temperature, high-pressure, top-loading technology, which is applied to valve devices, cocks including cut-off devices, engine components, etc., can solve problems such as not solving existing problems, and achieve the effect of preventing valve seat rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

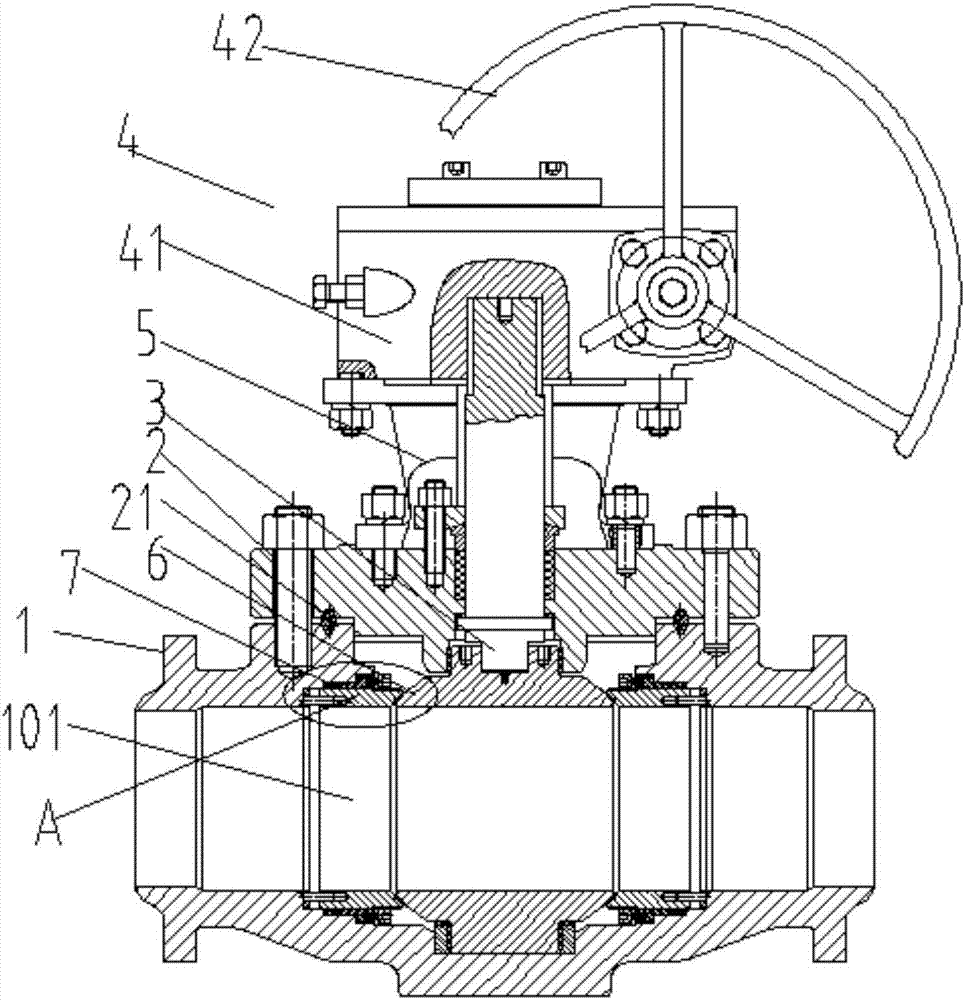

[0022] Such as Figure 1-2 As shown, a high-temperature and high-pressure top-entry ball valve includes a valve body 1, a valve cover 2 arranged on the valve body 1, a valve stem 3 and an actuator 4. The valve cover 2 and the valve body 1 are fixedly connected by bolts, and the valve cover 2 A sealing ring 21 is provided between the valve body 1 and the valve body 1 . The actuator 4 includes a worm case 41 and a rotating wheel 42 arranged on the worm case 41 . A bracket 5 is provided between the worm case 41 and the valve cover 2 . Both ends of the bracket 5 are respectively connected to the worm case 41 and the valve cover 2 . The inner chamber of the valve body 1 is provided with a ball 6 and a valve seat assembly 7 which are tightly fitted. The sealing structure 9 on the seat 8, the sealing structure 9 includes a spring pressing plate 91, a spring 92 and a valve seat packing self-sealing structure 93 connected in sequence, the spring pressing plate 91 is movable on the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com