Automatic lithium battery pole piece coating machine

A coating machine and lithium battery technology, applied in the field of coating machines, can solve problems such as complex structure, uneven coating thickness, and waste of paint in intermittent coating machines, and achieve simple structure, convenient production, and reduced post-sequence work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

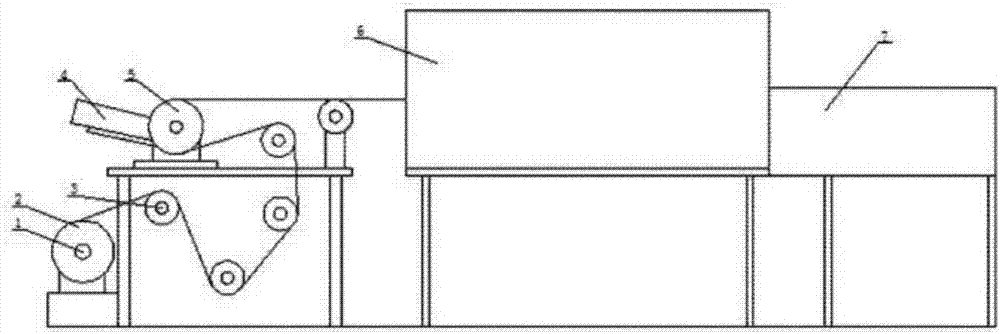

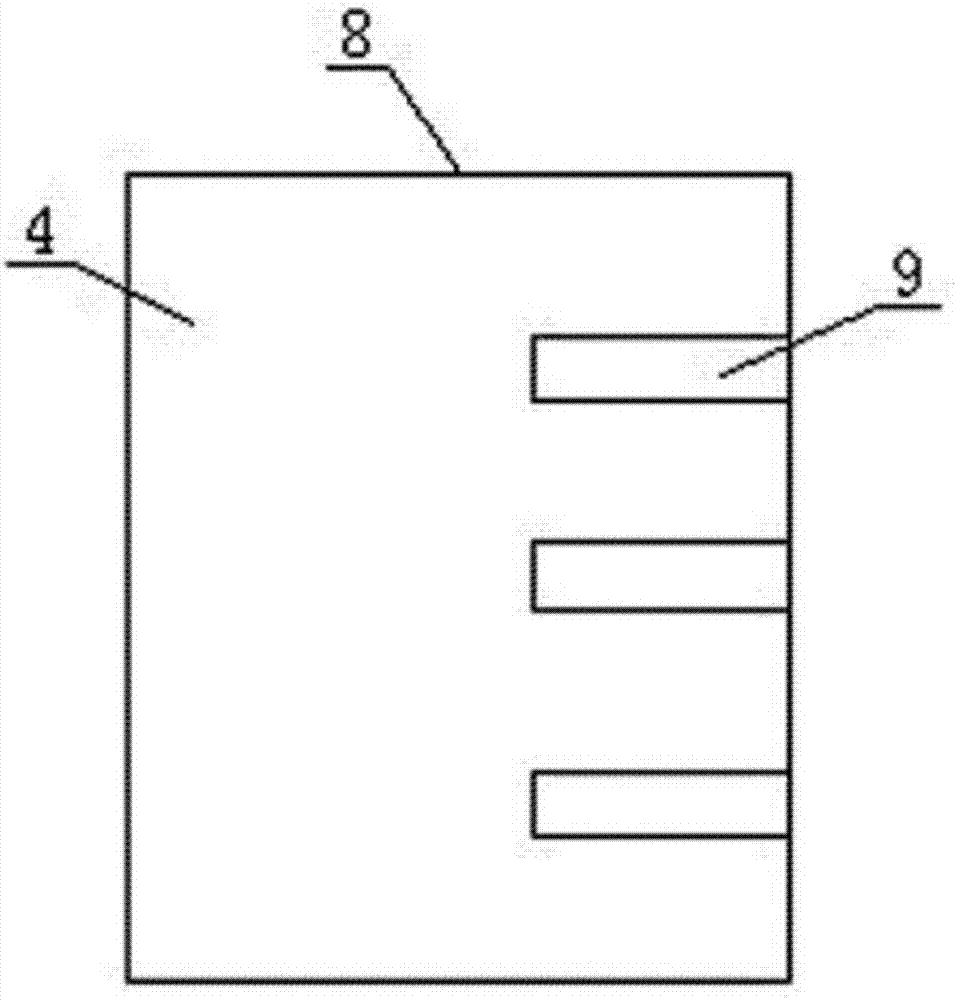

[0031] The lithium battery pole piece automatic coating machine includes an unwinding device, a tension adjusting device is installed at the back end of the unwinding device, a slurry coating device is installed at the back end of the tension adjusting device, and a drying device is installed at the back end of the slurry coating device. A rewinding device is installed at the rear end of the drying device; the unwinding device is mainly composed of an unwinding roller on which a pole piece roll is installed, and the tension adjusting device is mainly composed of a set of tension adjusting rollers; the slurry coating device includes a set of tension adjusting rollers. The coating roller and the die head that the battery slurry is coated on the pole piece, the die head is matched in parallel with one side of the coating roller, and the outlet of the die head is facing the coating roller; the outlet in the die head is provided with three sheet-shaped pads The die is divided into f...

Embodiment 2

[0033]The lithium battery pole piece automatic coating machine includes an unwinding device, a tension adjusting device is installed at the back end of the unwinding device, a slurry coating device is installed at the back end of the tension adjusting device, and a drying device is installed at the back end of the slurry coating device. A rewinding device is installed at the rear end of the drying device; the unwinding device is mainly composed of an unwinding roller on which a pole piece roll is installed, and the tension adjusting device is mainly composed of a set of tension adjusting rollers; the slurry coating device includes The coating roller and the die head that the battery slurry is coated on the pole piece, the die head is matched in parallel with one side of the coating roller, and the outlet of the die head is facing the coating roller; the outlet in the die head is provided with two strip-shaped The spacer divides the die into three areas, and the height of the sp...

Embodiment 3

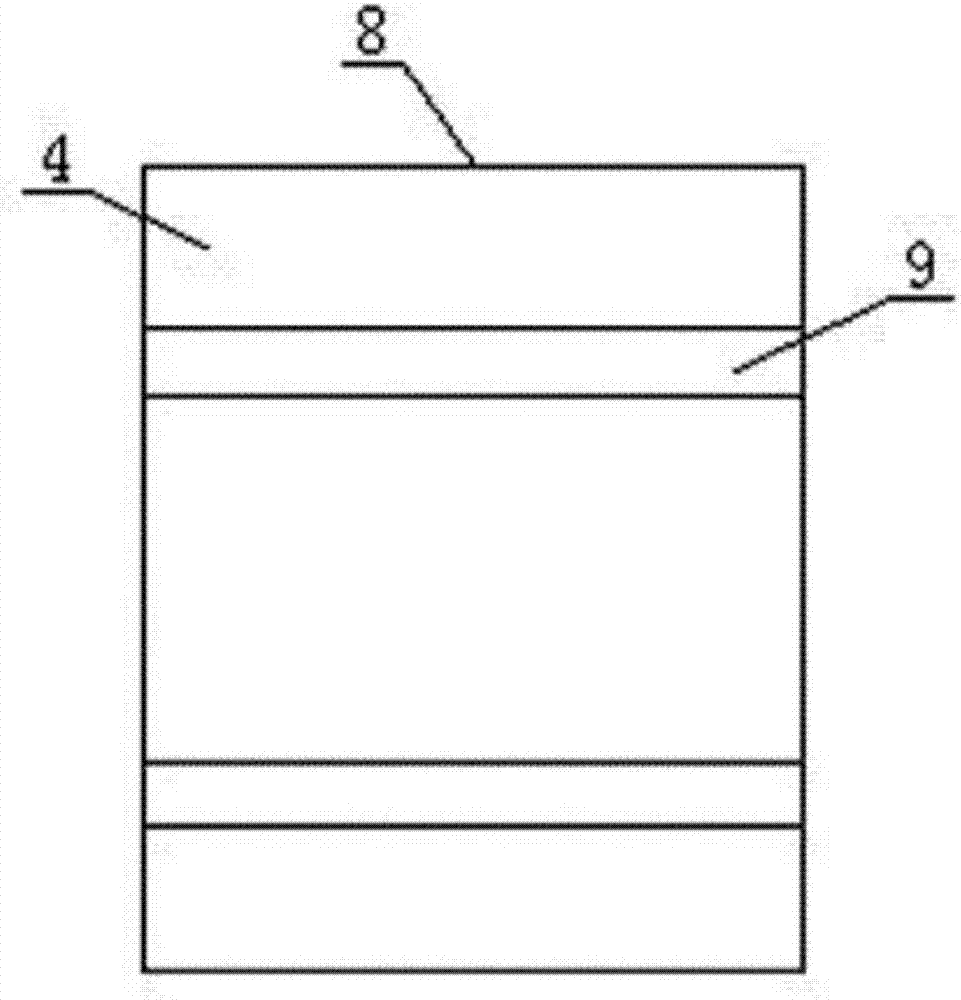

[0035] The lithium battery pole piece automatic coating machine includes an unwinding device, a tension adjusting device is installed at the back end of the unwinding device, a slurry coating device is installed at the back end of the tension adjusting device, and a drying device is installed at the back end of the slurry coating device. A rewinding device is installed at the rear end of the drying device; the unwinding device is mainly composed of an unwinding roller on which a pole piece roll is installed, and the tension adjusting device is mainly composed of a set of tension adjusting rollers; the slurry coating device includes The coating roller and the die for coating the battery slurry on the pole piece, the die is arranged in parallel on one side of the coating roller, and the outlet of the die is facing the coating roller; the outlet in the die is provided with three strip-shaped Gasket, the die head is divided into four areas, a gasket is arranged in the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com