Broken stone crushing and sorting device for road construction

A sorting device and road construction technology, applied in the direction of using liquid separation agent, solid separation, separation method, etc., can solve problems such as poor laying effect, uneven stone particle size, and inability to fully meet the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

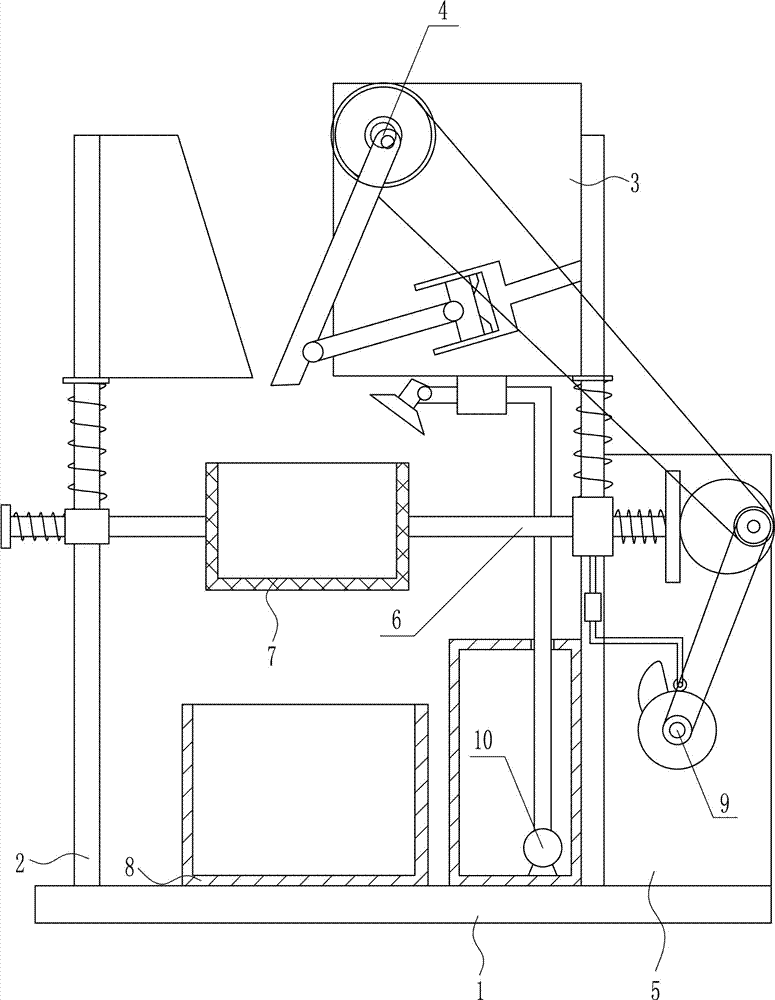

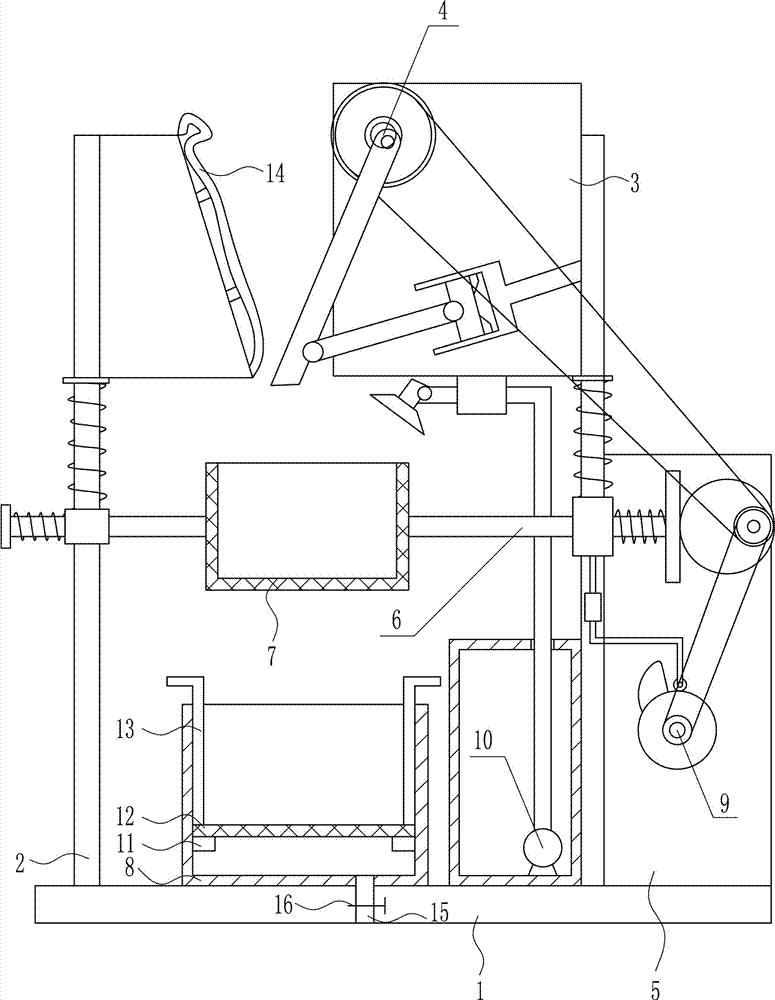

[0038] A crushing and sorting device for road construction, such as Figure 1-7 As shown, it includes a bottom plate 1, a pole 2, a first fixed plate 3, a crushing mechanism 4, a second fixed plate 5, a sorting mechanism 6, a sorting box 7 and a collection box 8, and the left and right sides of the top of the bottom plate 1 are vertical Connected with a pole 2, the left side of the top of the right pole 2 is provided with a first fixed plate 3, the front side of the first fixed plate 3 is equipped with a crushing mechanism 4, and the right pole 2 is connected with a second fixed plate 5, The second fixed plate 5 is positioned at the top of the bottom plate 1, and a sorting mechanism 6 is installed between the poles 2 on the left and right sides. A collection box 8, the collection box 8 is located on the top of the bottom plate 1.

Embodiment 2

[0040] A crushing and sorting device for road construction, such as Figure 1-7 As shown, it includes a bottom plate 1, a pole 2, a first fixed plate 3, a crushing mechanism 4, a second fixed plate 5, a sorting mechanism 6, a sorting box 7 and a collection box 8, and the left and right sides of the top of the bottom plate 1 are vertical Connected with a pole 2, the left side of the top of the right pole 2 is provided with a first fixed plate 3, the front side of the first fixed plate 3 is equipped with a crushing mechanism 4, and the right pole 2 is connected with a second fixed plate 5, The second fixed plate 5 is positioned at the top of the bottom plate 1, and a sorting mechanism 6 is installed between the poles 2 on the left and right sides. A collection box 8, the collection box 8 is located on the top of the bottom plate 1.

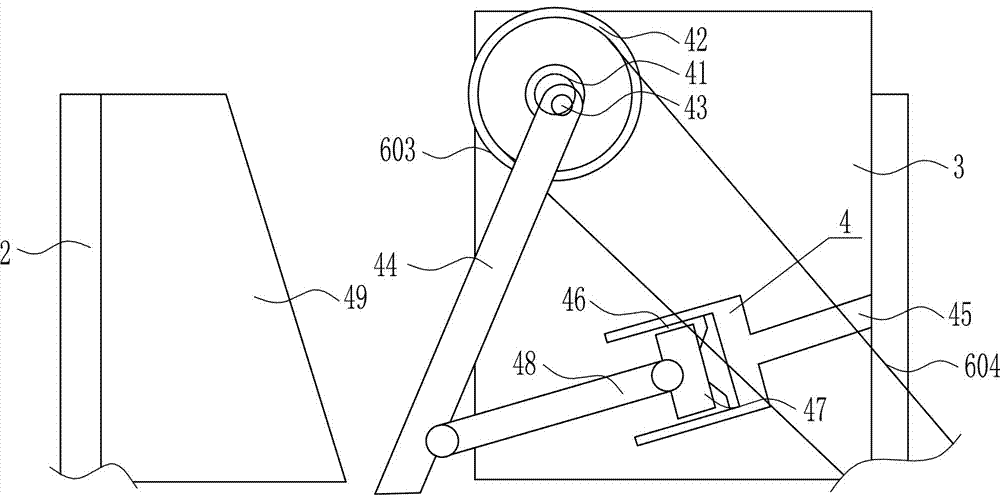

[0041] The crushing mechanism 4 includes a motor 41, a disc 42, an eccentric shaft 43, a crushing plate 44, fasteners 45, turnbuckle bolts 47, con...

Embodiment 3

[0043] A crushing and sorting device for road construction, such as Figure 1-7 As shown, it includes a bottom plate 1, a pole 2, a first fixed plate 3, a crushing mechanism 4, a second fixed plate 5, a sorting mechanism 6, a sorting box 7 and a collection box 8, and the left and right sides of the top of the bottom plate 1 are vertical Connected with a pole 2, the left side of the top of the right pole 2 is provided with a first fixed plate 3, the front side of the first fixed plate 3 is equipped with a crushing mechanism 4, and the right pole 2 is connected with a second fixed plate 5, The second fixed plate 5 is positioned at the top of the bottom plate 1, and a sorting mechanism 6 is installed between the poles 2 on the left and right sides. A collection box 8, the collection box 8 is located on the top of the bottom plate 1.

[0044] The crushing mechanism 4 includes a motor 41, a disc 42, an eccentric shaft 43, a crushing plate 44, fasteners 45, turnbuckle bolts 47, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com