Breath-type waterproof power source structure

A technology of power supply and circuit board, which is applied in the direction of electrical components, electrical equipment shell/cabinet/drawer, casing/cabinet/drawer parts, etc., which can solve the problems of increasing gaps, gaps, etc., and achieve pressure balance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The breathable waterproof power supply structure of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

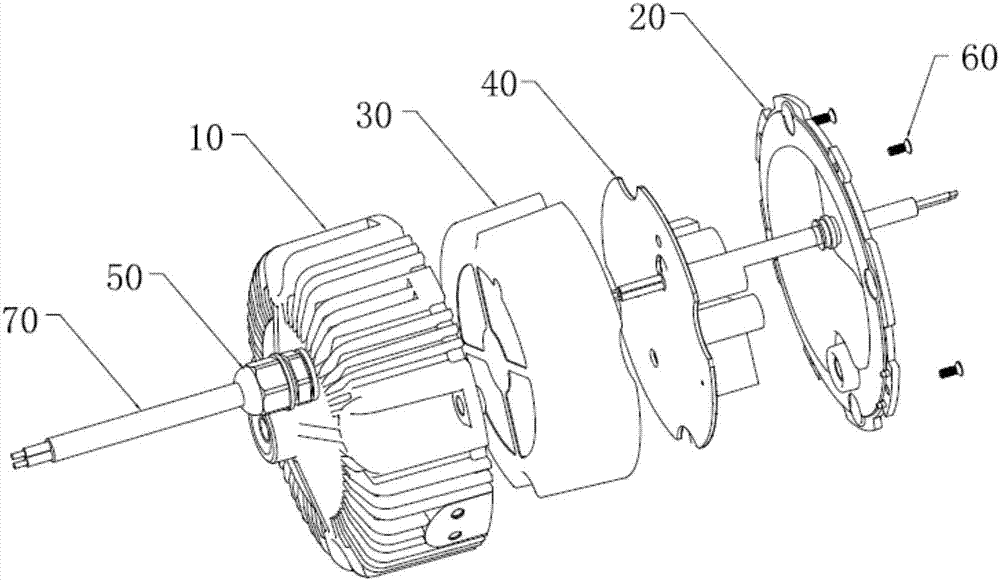

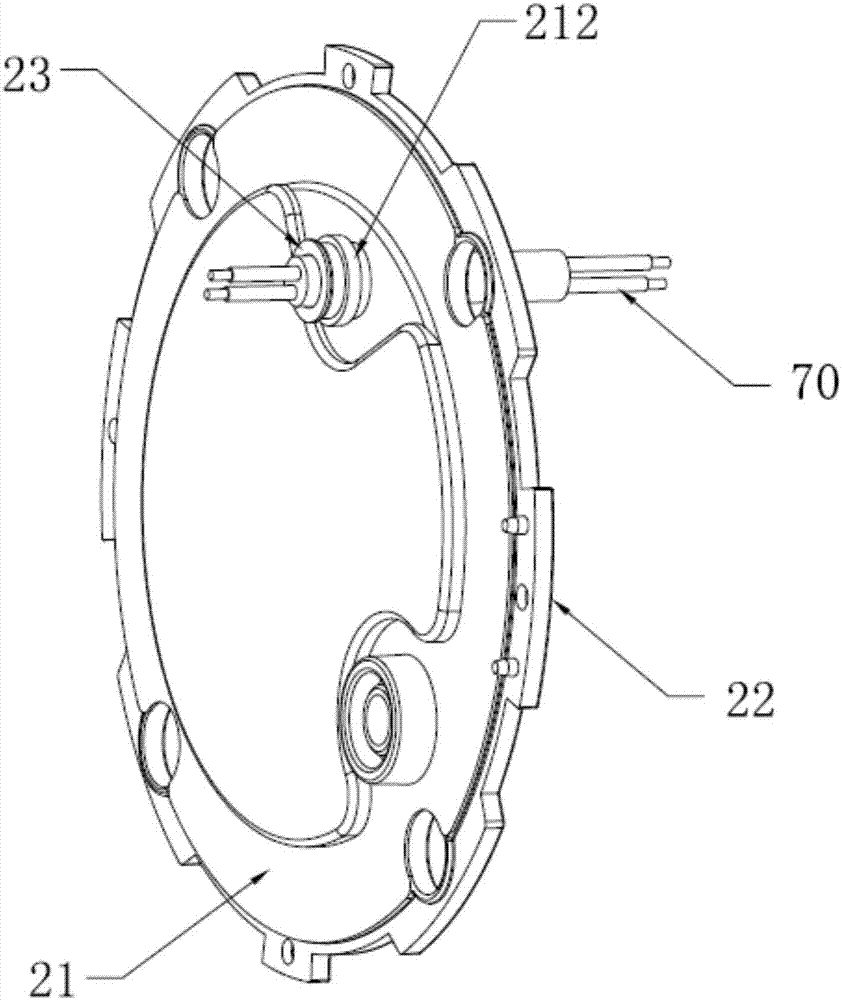

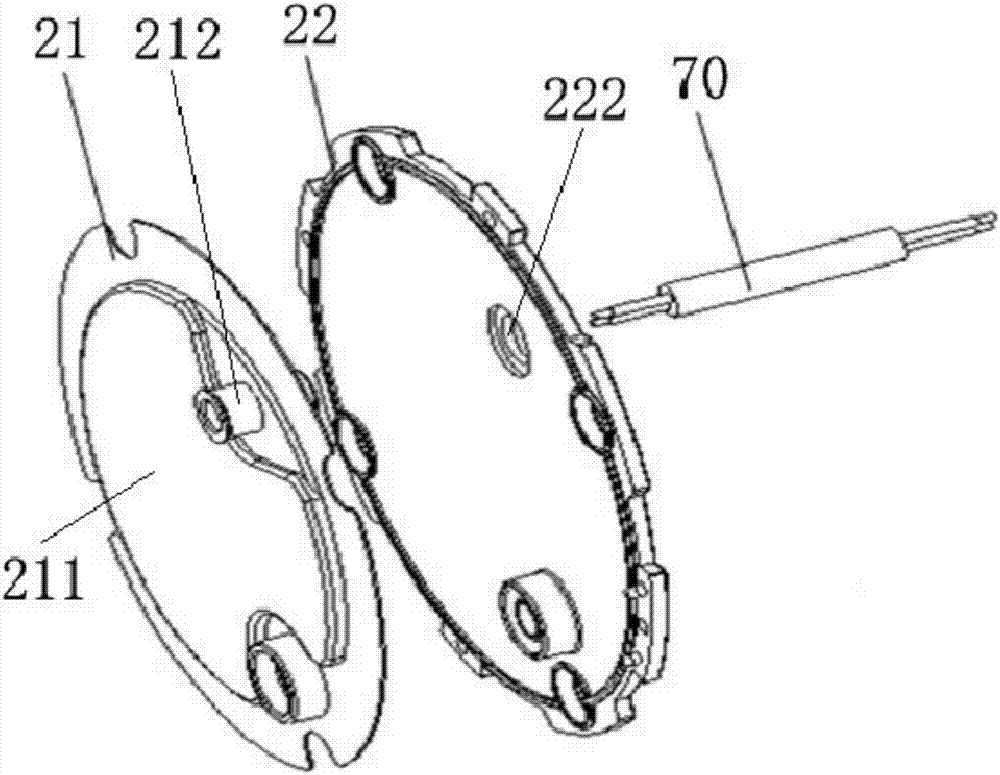

[0021] See figure 1 , a breathable waterproof power supply structure, which includes a cylindrical cup-shaped face cover 10, a circuit board 40 and an insulating sheet 30 are arranged in the face cover 10, the insulating sheet 30 is sleeved on the outside of the circuit board 40, and the circuit board 40 is connected with a wire 70 , and one end of the wire 70 passes through the insulating sheet 30 and the cover 10 to protrude to the outside. For ease of understanding and setting forth this scheme, take the cup-shaped opening of the face cover 10 as a reference plane in this case, and the direction extending toward the outside is behind, and the other direction opposite to it (that is, the cup-shaped bottom located at the face cover) One side) is the front.

[0022] preferred, see also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com