Radiograph drying machine

A technology of drying film and film, applied in the field of radiographic film drying machine, which can solve the problems of uneven drying of radiographic film, blurring of radiographic film, and affecting the quality of dry film, so as to avoid blurring of development, promote internal flow, and improve drying quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

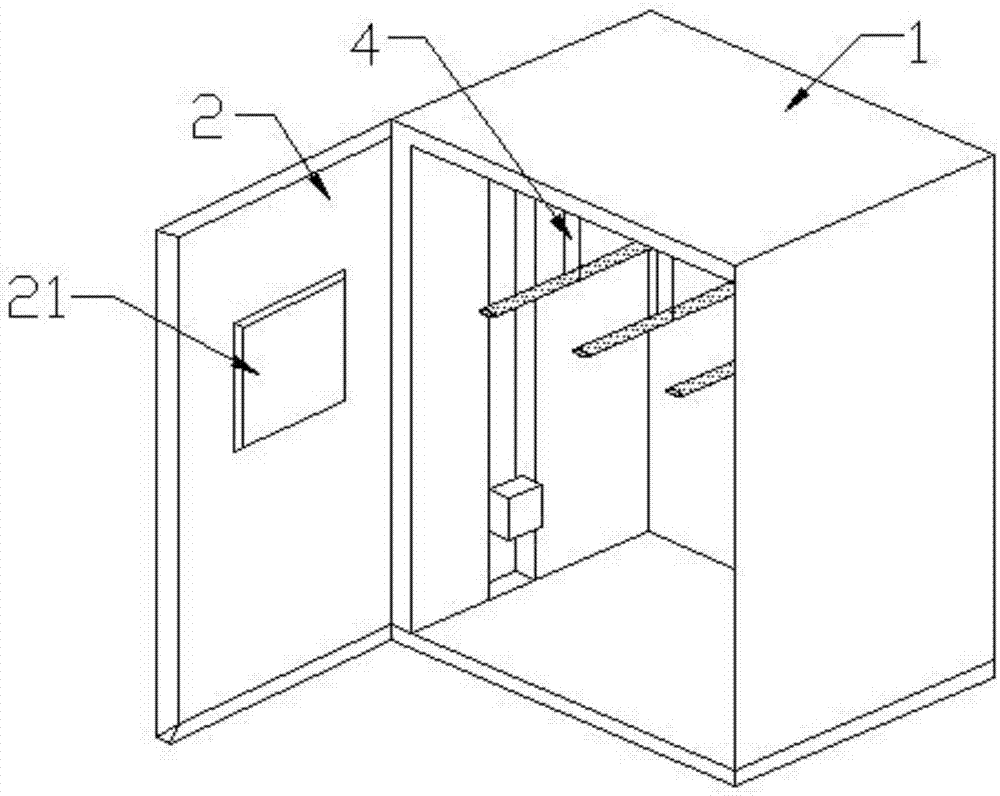

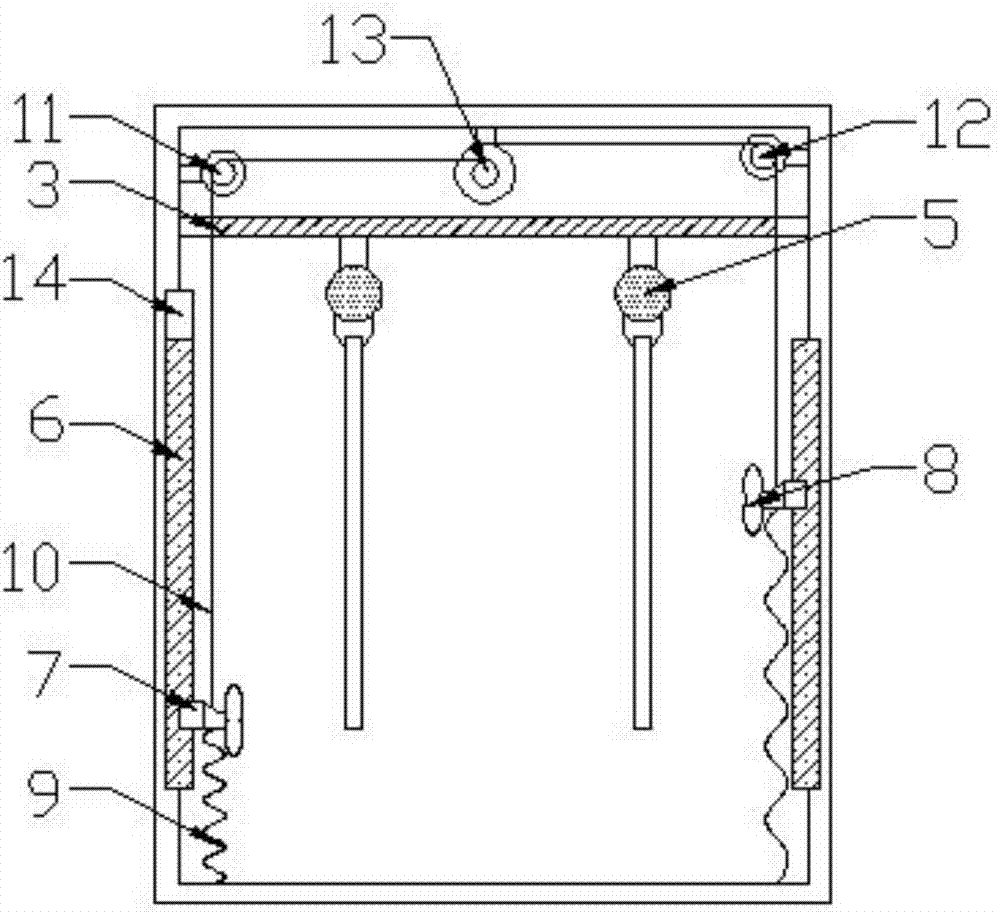

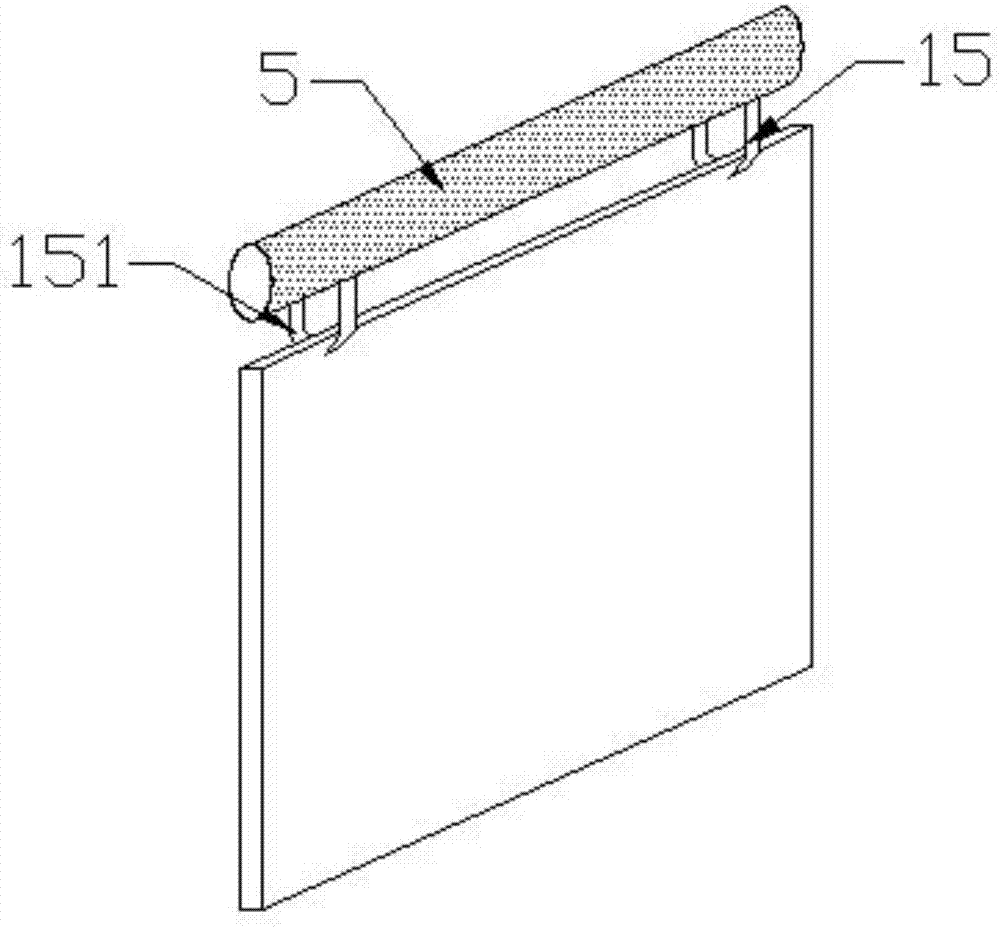

[0018] Such as Figure 1-3 As shown, a radiographic film drying machine includes a film drying machine housing 1, a machine door 2, a radiographic film suspension rod 5 and a temperature-controlling hot air blower 8, and an organic door 2 is installed on one side of the film drying machine housing 1 The top of the film drying machine housing 1 is equipped with a horizontal plate 3 through the connecting rod 4, and the bottom of the horizontal plate 3 is equipped with a plurality of radiographic negative film suspension rods 5, and the two opposite sides of the film drying machine housing 1 A side guide rail 6 is installed on the side, and a slide seat 7 is slidably installed on the side guide rail 6, and a temperature control hot air blower 8 is installed on the slide seat 7, and the bottom of the slide seat 7 is connected with the back spring 9. One end is connected, and the other end of described back-moving spring 9 is installed on the bottom of drying sheet machine housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com