Colored gradient light-reducing mirror and a method of manufacturing the same

A dimming mirror and colored technology, which is applied in optics, optical filters, optical components, etc., can solve problems such as inability to focus, scratches on the surface of resin sheets, and short service life, achieving clear and realistic pictures, improving service life, and shooting The effect of relaxing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

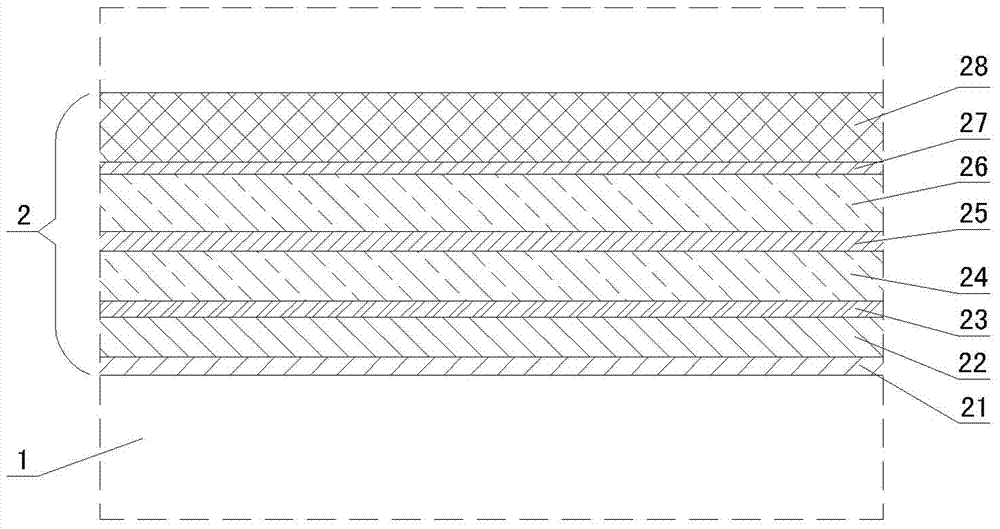

[0038] Such as Figure 1-Figure 2 As shown, the colored gradient dimming mirror of the present invention includes a glass lens 1 and a vacuum coating layer 2 coated on the glass lens 1, and the vacuum coating layer 2 includes Al with a thickness of 8.13nm from the inside to the outside. 2 o 3 The film layer 21, the Cr film layer 22 with a thickness of 55.29nm, the H with a thickness of 6.14nm 4 Film layer 23, the first layer of SiO with a thickness of 76.32nm 2 Film layer 24, a Ni film layer 25 with a thickness of 8.76nm, and a second layer of SiO with a thickness of 84.36nm 2 The film layer 26, the Fe film layer 27 with a thickness of 3.52 nm, and the SV-55 film layer 28 with a thickness of 87.80 nm. Of course, the thickness of each film layer is the optimal thickness in this embodiment, and each film layer can also be set to other thicknesses according to actual usage needs. Wherein, the SV-55 film layer 28 adopts SiO 2 and Al 2 o 3 The composition of the mixture is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com