Detection device capable of automatic adjusting installation angle of radar level gauge

A technology of installation angle and automatic adjustment, which is applied in the direction of measuring device, measuring angle, engine lubrication, etc., can solve the problems of low adjustment accuracy, high skill requirements of operators, and inability to achieve precise control, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

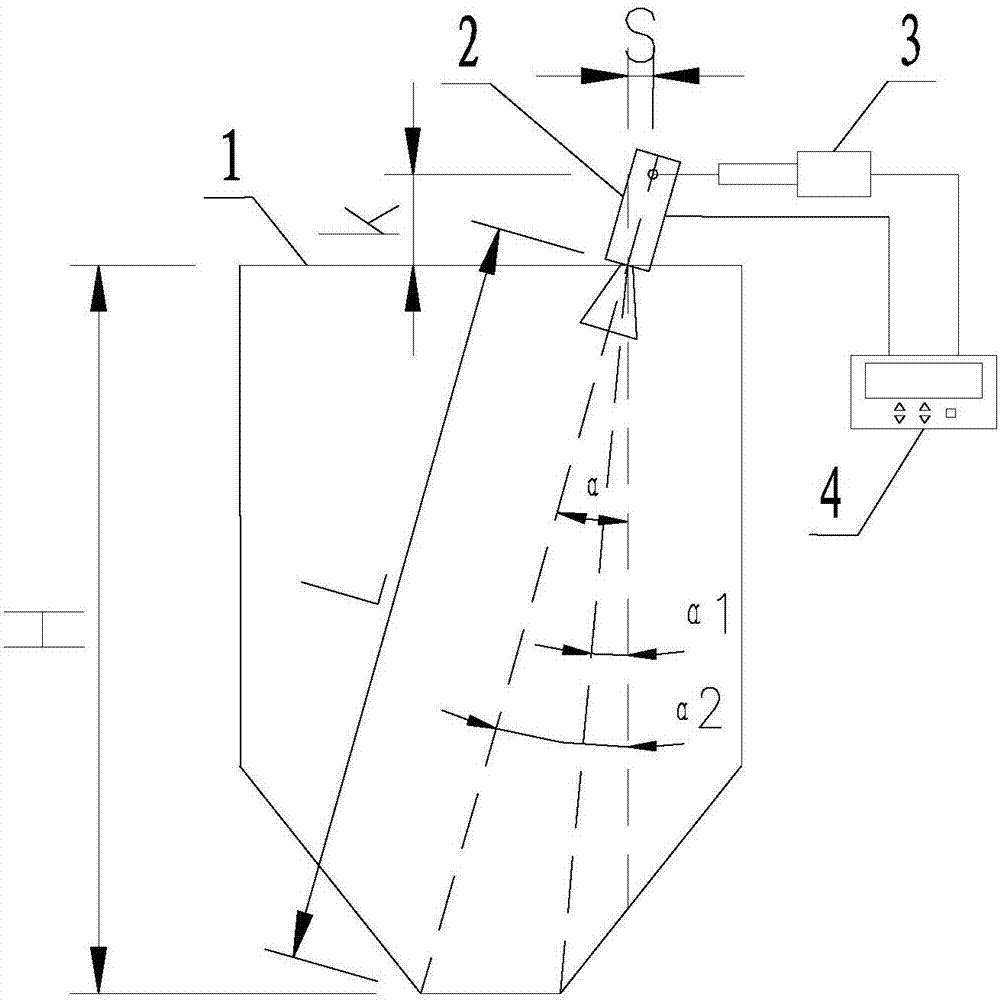

[0015] Such as figure 2 As shown, the present invention is a detection device for automatically adjusting the installation angle of a radar level gauge, which includes a radar level gauge 2 , a linear actuator 3 and a controller 4 . The silo 1 includes a cylindrical structure in the upper half and a conical structure in the lower half. The radar level gauge 2 is located on the top of the silo 1, and is set offset to avoid the position of the feeding hole in the middle of the silo. The linear actuator 3 includes a horizontal tie rod that can be stretched back and forth horizontally. One end of the horizontal tie rod is fixedly connected with the radar level gauge 2 and drives the radar level gauge 2 to rotate around a fixed fulcrum. The above-mentioned straight stroke actuator 3 and radar level gauge 2 are respectively connected with the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com