Packaging structure and method for electric plugging-pulling mechanism of launching device

A plug-in mechanism and launching device technology, which is applied in the direction of projectiles, weapon accessories, ammunition, etc., can solve the problems of complex space positioning and fastening of metal plates, ablation of plug-in mechanism, and difficult operation, so as to save launch preparation time , Simplified installation, solve the effect of on-site installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

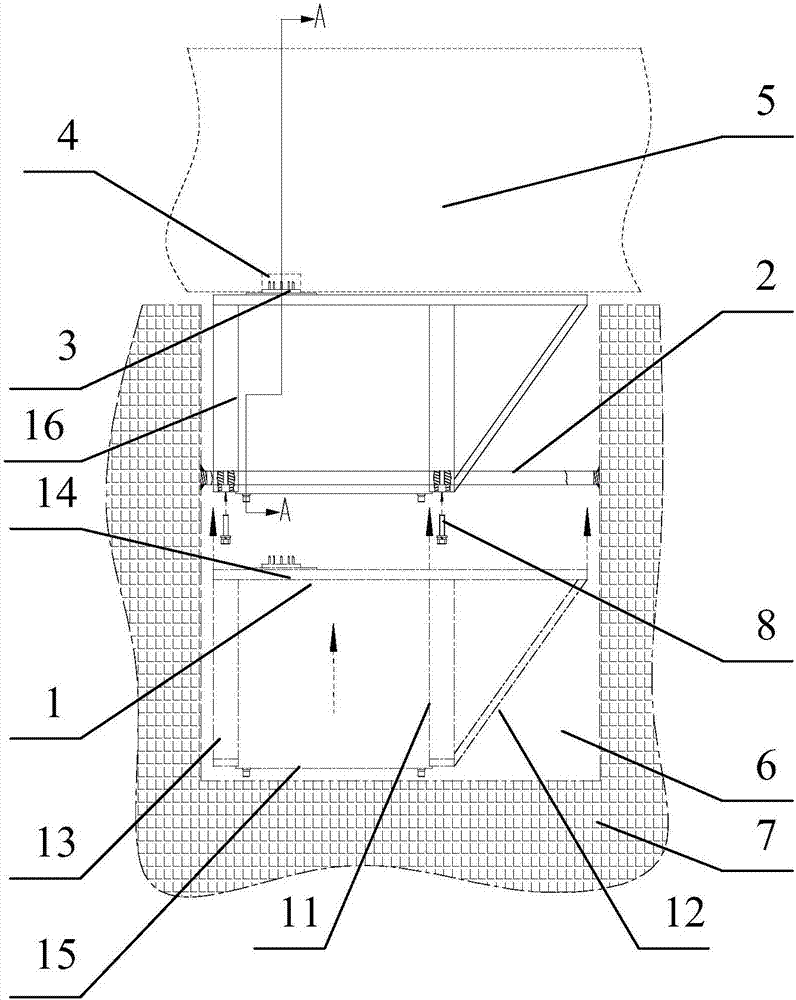

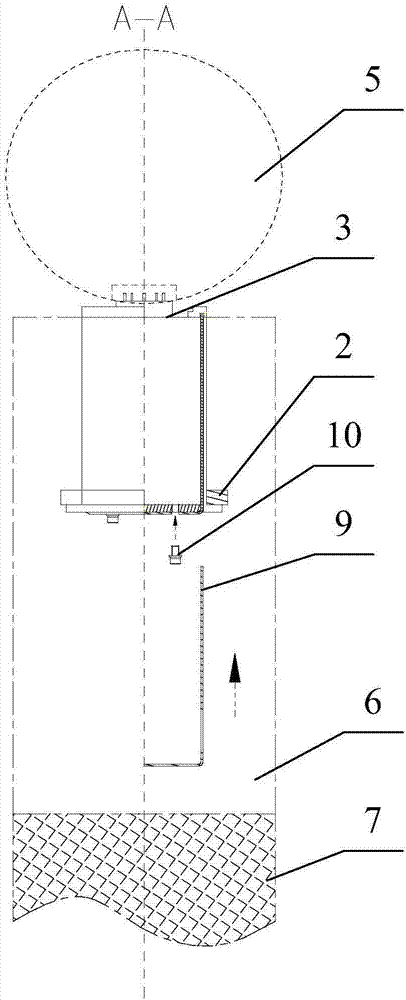

[0022] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0023] Such as Figure 1 to Figure 3 As shown, the packaging structure of the electric plug-in mechanism of the launcher of the present invention includes a plug-in mechanism box body mounting plate 2, an electric plug 3, a projectile socket 4, a projectile 5, a launcher cavity 6, a launcher body 7, a plug-in mechanism Mechanism box set screw 8, flame shield 16, a plug-in mechanism box 1 includes rear cover plate 11, diagonal brace 12, front cover plate 13, upper cover plate 14, bottom plate 15, cover plate installation includes cover plate 9 , sealing plate set screw 10, the plug-in mechanism box body 1 is positioned at the bottom of the plug-in mechanism box body mounting plate 2, the plug-in mechanism box body mounting plate 2 is connected with the plug-in mechanism box body set screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com