Water conveying pipe for industrial machinery

A technology for industrial machinery and water pipes, applied in mechanical equipment, hoses, pipes, etc., can solve the problems of poor connection stability, inconvenient pipe layout, easy damage at joints, etc., and achieve the effect of good stability and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

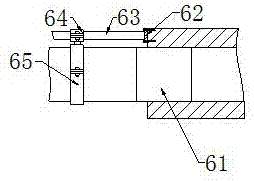

Image

Examples

specific Embodiment approach

[0023] Specific embodiments: when the staff uses the present invention, they adjust the height of the hard pipe 4 according to the height of the connection position. When adjusting, the staff makes the hydraulic lift 2 run, and the work of the hydraulic lift 2 drives the lower clamp ring 35 to move, and the lower clamp ring 35 The movement drives the hard pipe 4 to move. When the hard pipe 4 moves to a suitable position, the staff stops the hydraulic lift 2 and connects the connector 31 with the water inlet of the industrial machine. The adaptability of the invention avoids the situation that the hard pipe 4 cannot be docked with the water inlet of the industrial machine. When the hard pipe 4 is damaged, the staff makes the electric telescopic column 34 run, and the electric telescopic column 34 works to drive the upper clamp ring 33 to move. Thereby the upper clamp ring 33 is separated from the hard pipe 4, and the staff takes out the hard pipe 4 from the lower clamp ring 35 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com