Mortise and tenon building structure system

A technology of building structure and mortise and tenon, which is applied in the direction of building structure, building, housing structure support, etc., can solve the problems of spending a lot of time on scaffolding, poor construction environment, and high labor intensity, so as to improve construction efficiency, ensure stability, The effect of simplifying the lap joint process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

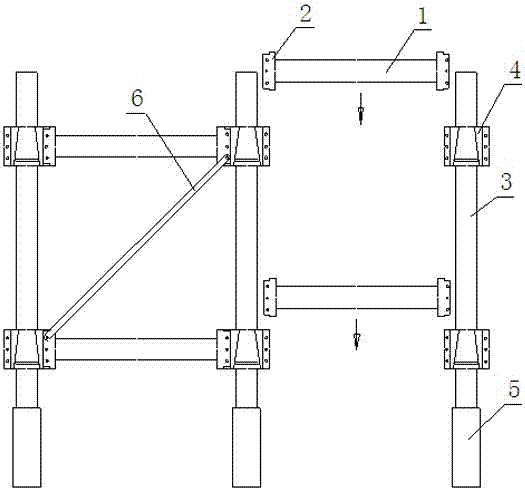

[0028] Attached below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 The mortise and tenon building structure system of the present invention is further described in detail:

[0029] The mortise and tenon building structure system of the present invention includes a set of horizontal support units, a set of vertical support units, and a set of diagonal bars 6 .

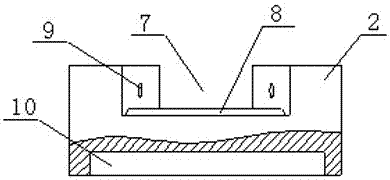

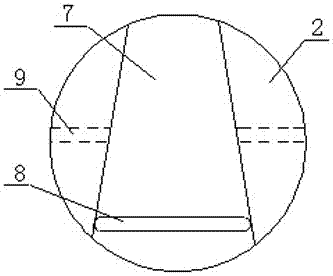

[0030] The transverse support unit includes a transverse bar 1 and two transverse connectors 2 fixed at both ends of the transverse bar 1 . The transverse connector 2 is cylindrical, and the inner end surface of the transverse connector 2 is welded on the end surface of the cross bar 1. The cross bar 1 is a hollow round tube. Cooperating grooves 10 and protrusions.

[0031] The longitudinal support unit includes a vertical pole 3 , a connecting sleeve 5 fixed at the bottom of the vertical pole 3 , and two columnar longitudinal connectors 4 close to the upper and lower ends of the vertical pole 3 and sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com