Structural phase transition type radial shrinkable tube fabric and its preparation method and application

A phase transition and fabric technology, applied in the direction of fabrics, multi-strand fabrics, textiles, etc., can solve the problems of tube fabrics that do not involve radial shrinkage and expansion, and tube fabrics that do not involve, achieve compact and stable structure, convenient preparation, low tension The effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

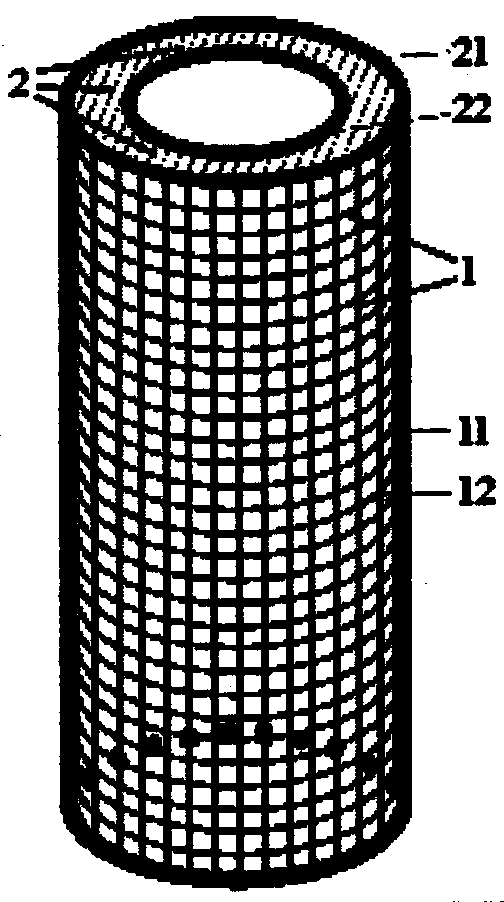

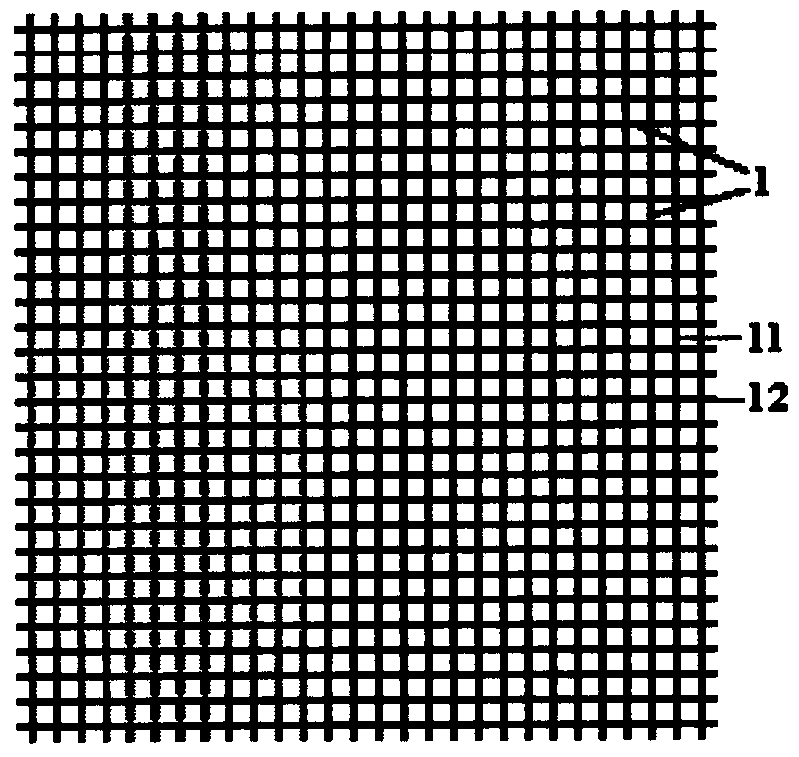

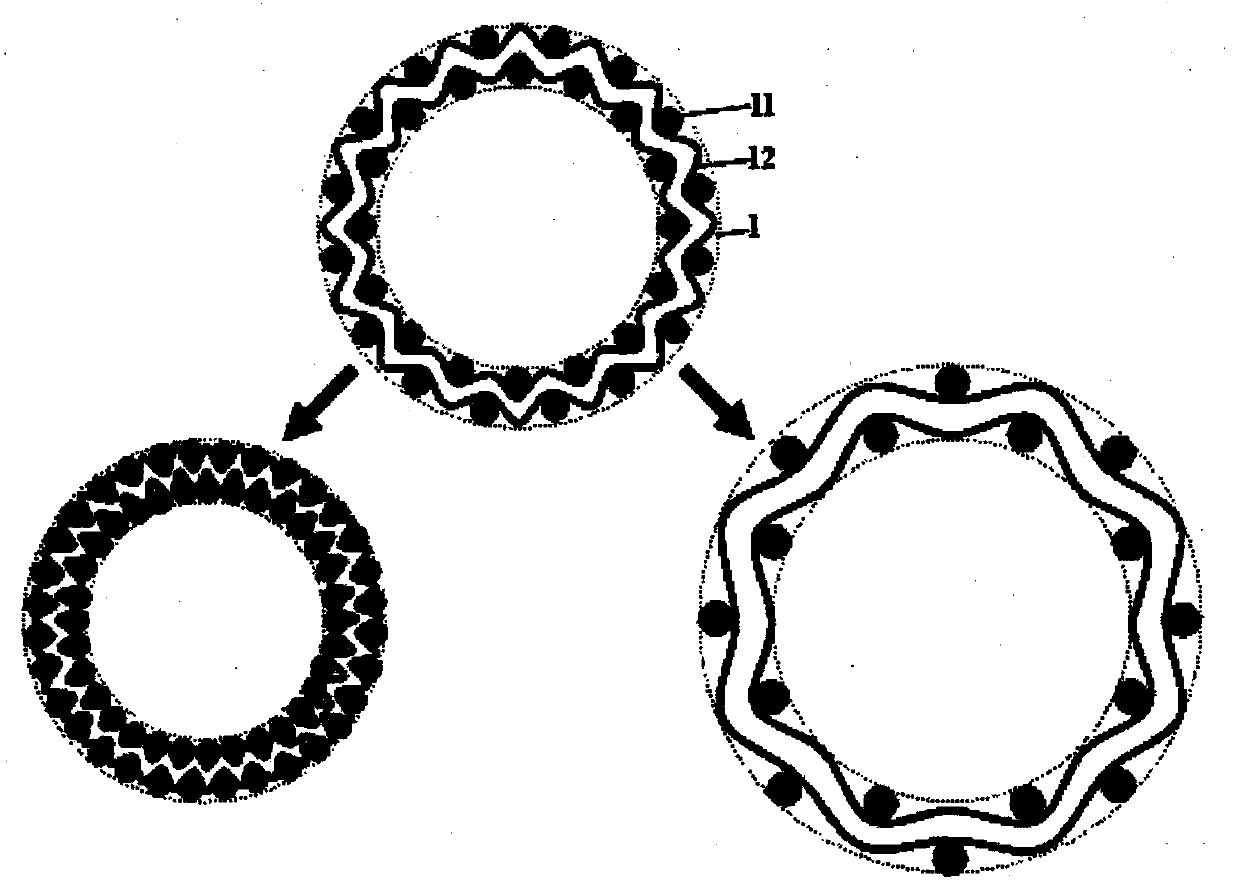

[0031] Such as Figure 1a - As shown in -b and 2, it is a structural phase change type radial shrinkable tube fabric provided by the present invention. The tube fabric 1 is formed by interweaving weaving yarns 12 and high-tension warp yarns 11 by using a double-layer fabric to circulate back and forth. The radially expandable tubular structure fabric.

[0032] The warp yarn 11 of the tube fabric 1 adopts relatively thick low-twisted, high-strength, high-modulus Kevlar filament tow, which is a linear elastic body, and the elongation at break is not more than 10%.

[0033] The weft yarn 12 of the tube fabric 1 is made of relatively fine denier twisted and crimped Nomex filament yarn, and the elongation at break is not more than 10%.

[0034] The above tube fabric 1 is characterized by:

[0035] ① During the drawing process of the tube fabric 1, the warp yarn 11 undergoes a small elastic shrinkage, and the maximum elastic shrinkage does not exceed 10%, so as to ensure that the l...

Embodiment 2

[0046] Such as Figure 1a - As shown in -b and 2, it is a structural phase change type radial shrinkable tube fabric provided by the present invention. The tube fabric 1 is formed by interweaving weaving yarns 12 and high-tension warp yarns 11 by using a double-layer fabric to circulate back and forth. The radially expandable tubular structure fabric.

[0047] The warp yarn 11 of the tube fabric 1 adopts relatively thick low-twisted, high-strength, high-modulus Kevlar filament tow, which is a linear elastic body, and the elongation at break is not more than 10%.

[0048] The weft yarn 12 of the tube fabric 1 is made of relatively fine denier twisted and crimped PBO filament yarn, and the elongation at break is not more than 10%.

[0049] The above tube fabric 1 is characterized by:

[0050] ① During the drawing process of the tube fabric 1, the warp yarn 11 undergoes a small elastic shrinkage, and the maximum elastic shrinkage does not exceed 10%, so as to ensure that the low...

Embodiment 3

[0061] Such as Figure 1a - As shown in -b and 2, it is a structural phase change type radial shrinkable tube fabric provided by the present invention. The tube fabric 1 is formed by interweaving weaving yarns 12 and high-tension warp yarns 11 by using a double-layer fabric to circulate back and forth. The radially expandable tubular structure fabric.

[0062] The warp yarn 11 of the tube fabric 1 adopts relatively thick low-twisted, high-strength, high-modulus Kevlar filament tow, which is a linear elastic body, and the elongation at break is not more than 10%.

[0063] The weft yarn 12 of the tube fabric 1 is made of relatively fine denier twisted and crimped PI filament yarn, and the elongation at break is not more than 10%.

[0064] The above tube fabric 1 is characterized by:

[0065] ① During the drawing process of the tube fabric 1, the warp yarn 11 undergoes a small elastic shrinkage, and the maximum elastic shrinkage does not exceed 10%, so as to ensure that the low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com