Quantitative automatic subpackaging equipment

A dispensing and equipment technology, which is applied in the field of equipment that can quantitatively and automatically dispense, can solve the problems of unstable feeding speed, medicine weight measurement error, inaccurate dispensing weight, etc., and achieves uniform impact force and accurate weighing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

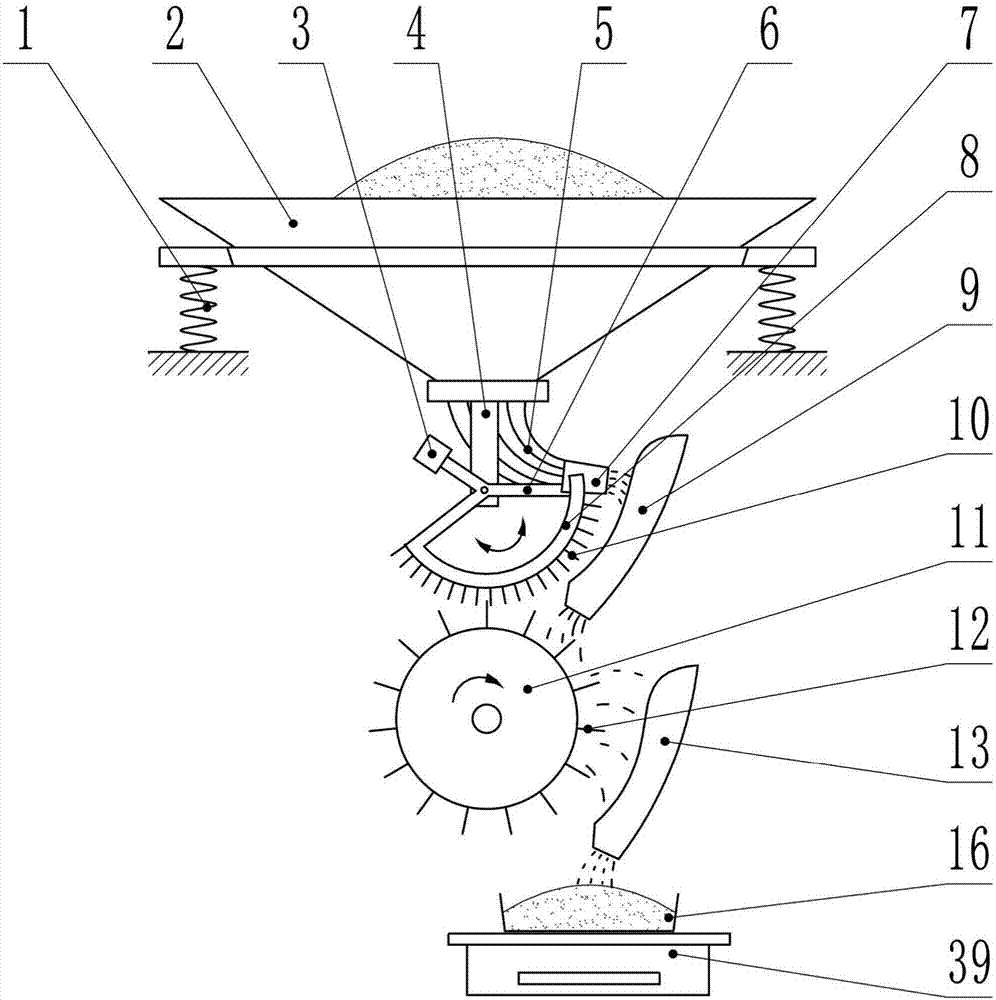

[0016] In embodiment 1, such as figure 1 As shown, the present invention includes a frame body, a lower hopper 2, a runner 11 and a weighing assembly. In order to facilitate the display of the internal structure, the frame structure has been partially omitted in the figure, and only the part connected to other structures is drawn, that is, the straight line with hatching in the figure (except for the section line). The frame structure is used to support, connect and fix other structures. Since the specific structure of the frame is determined by the position and size of other structures and has no impact on the working principle of the present invention, its specific structure will not be repeated.

[0017] The lower hopper 2 is in the shape of a funnel with a thick top and a thin bottom, and is used to accommodate medicines to be dispensed. The periphery of the lower hopper 2 is provided with a hopper spring 1, and the lower end of the hopper spring 1 is fixedly installed on...

Embodiment 2

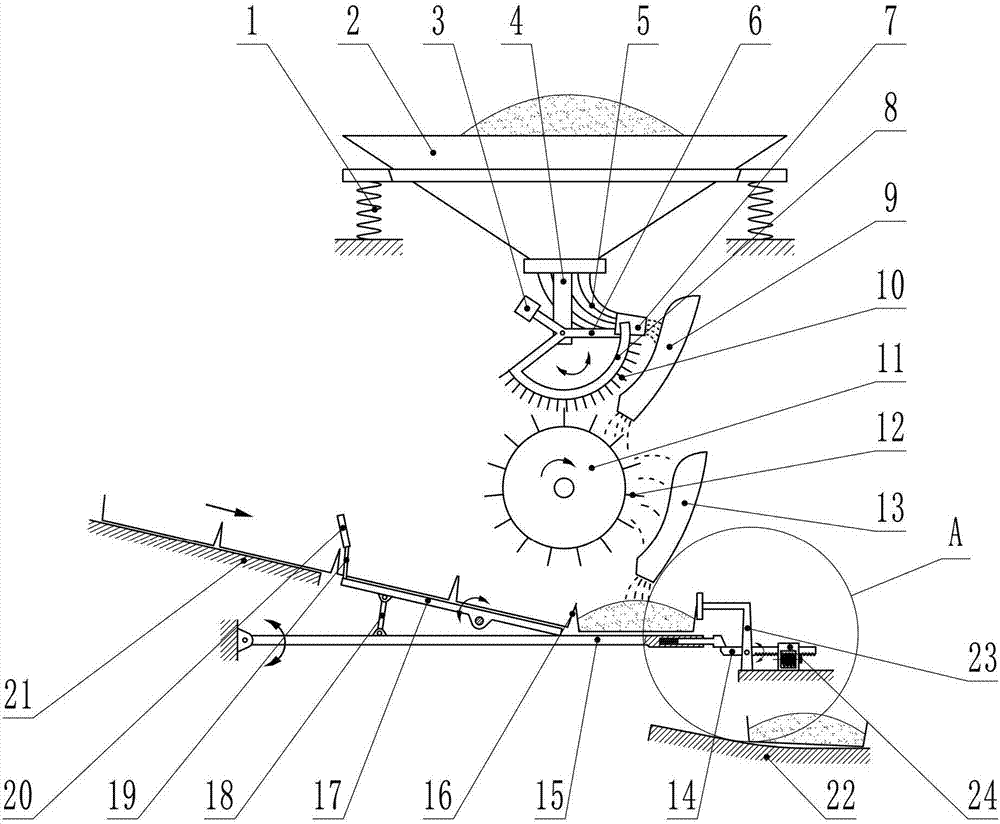

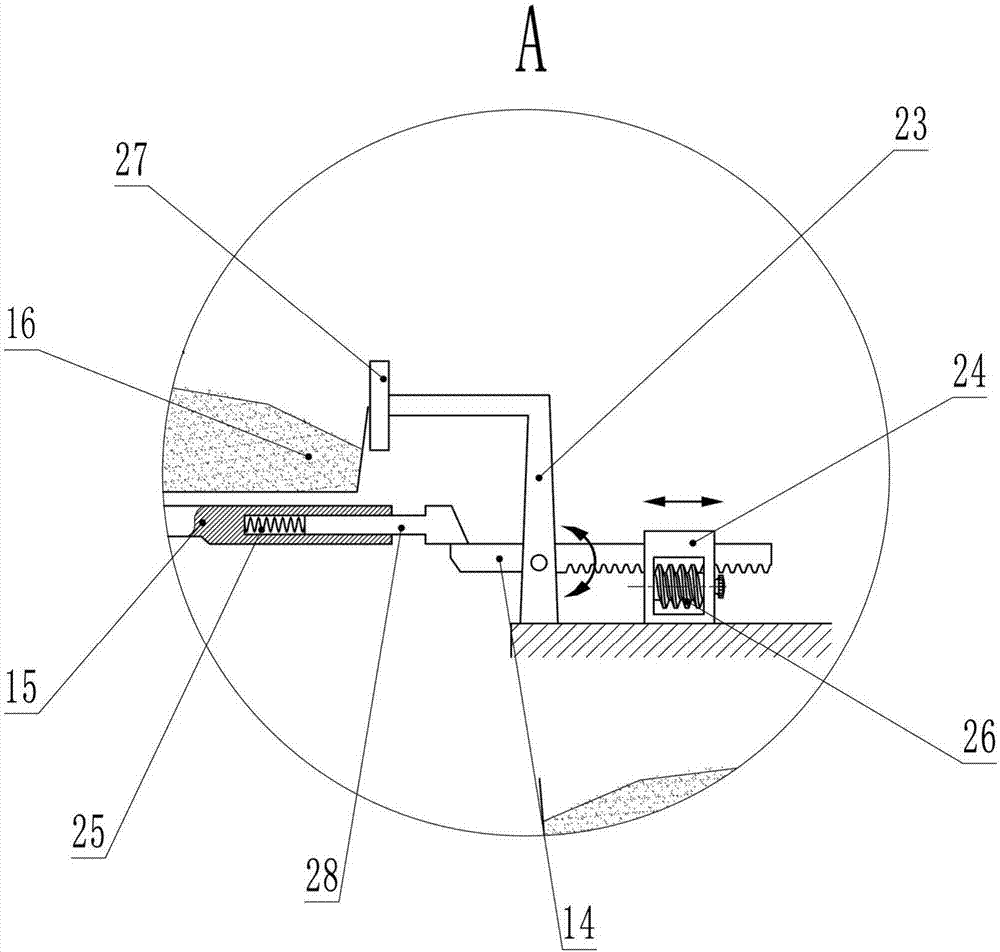

[0022] In embodiment 2, such as figure 2 , 3 As shown, the present embodiment includes a frame body, a lower hopper 2, a runner 11 and a weighing assembly. Wherein the lower hopper 2, the runner 11 and their auxiliary structures and connections are the same as those in Embodiment 1, and will not be repeated in this embodiment. The frame structure is adaptively changed according to the change of the structure of the weighing assembly. The difference between this embodiment and Embodiment 1 mainly lies in the change of the weighing assembly.

[0023]The weighing assembly is located below the runner 11 and includes No. 1 rack 21 , No. 2 rack 22 , No. 1 crossbeam 17 , No. 2 crossbeam 15 and No. 3 crossbeam 14 . The No. 1 disc rack 21 and the No. 2 disc rack 22 are fixed on the rack body (or it can be said to be a part of the rack body). The No. 1 rack 21, the No. 2 rack 22 and the No. 1 beam 17 are placed obliquely, the front is high and the rear is low. The No. 1 rack 21 is ...

Embodiment 3

[0027] In embodiment 3, such as Figure 4 As shown, the present embodiment includes a frame body, a lower hopper 2, a runner 11 and a weighing assembly. Wherein the lower hopper 2, the runner 11 and their subsidiary structures and connections are the same as those in Embodiment 1, and will not be repeated in this embodiment. The frame structure is adaptively changed according to the change of the structure of the weighing assembly. The difference between this embodiment and Embodiment 1 mainly lies in the change of the weighing assembly.

[0028] The weighing assembly includes No. 1 rack 21, No. 2 rack 22, No. 3 beam 14 and No. 4 beam 30, wherein No. 1 rack 21, No. 2 rack 22 and No. 3 beam 14 and No. 3 crossbeam 14's subsidiary structure and connection relationship thereof are the same as embodiment 2, and the present embodiment is no longer repeated. The middle position of the No. 4 beam 30 is hinged with the frame body, wherein a torsion spring is provided at the hinge, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com