Friction stir welding method for butt ring seam of large-scale weakly rigid hollow column members

A friction stir and welding method technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem of inability to meet the requirements of friction stir welding assembly accuracy, reduce height and complexity, and improve assembly accuracy. , The effect of improving welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

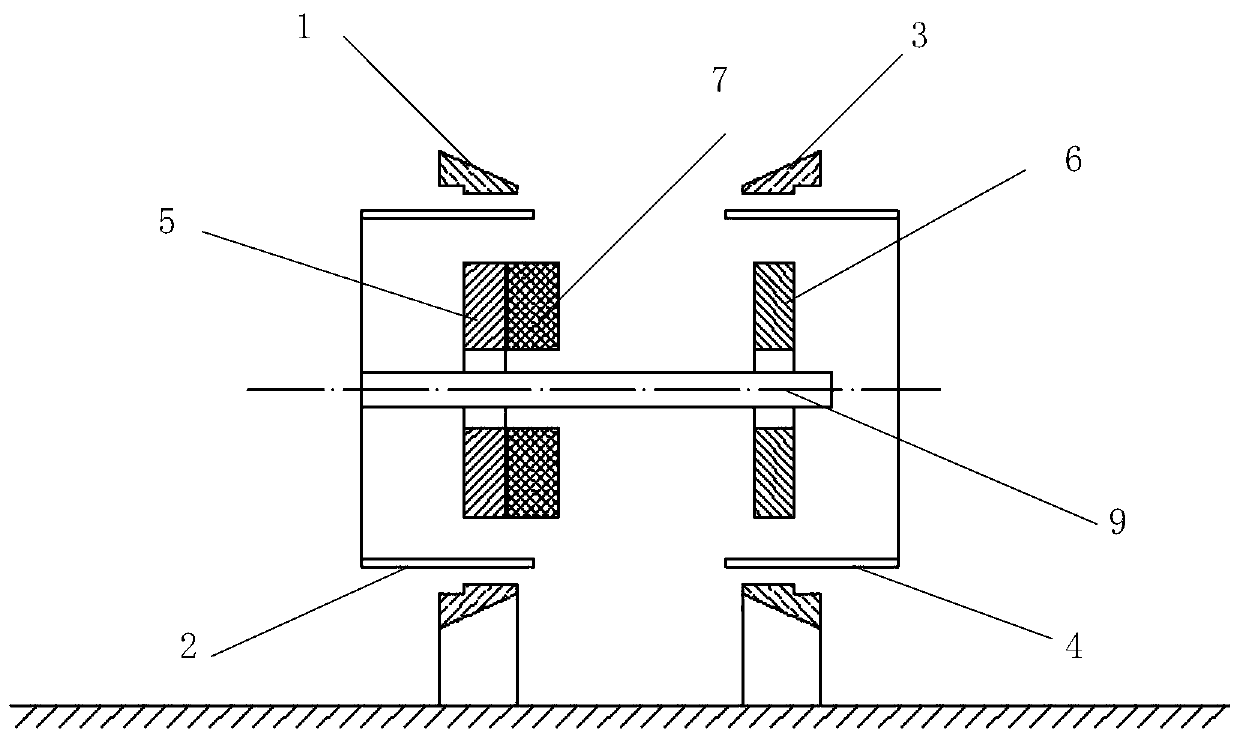

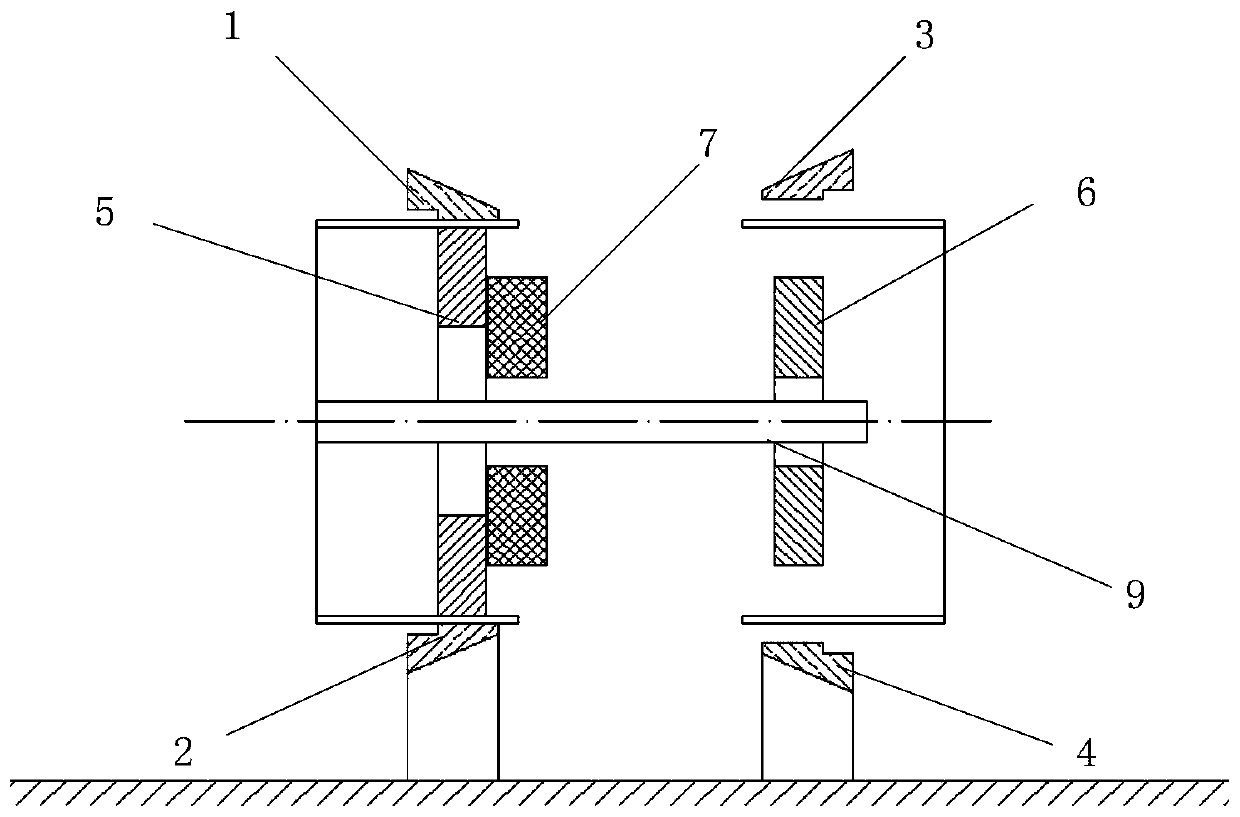

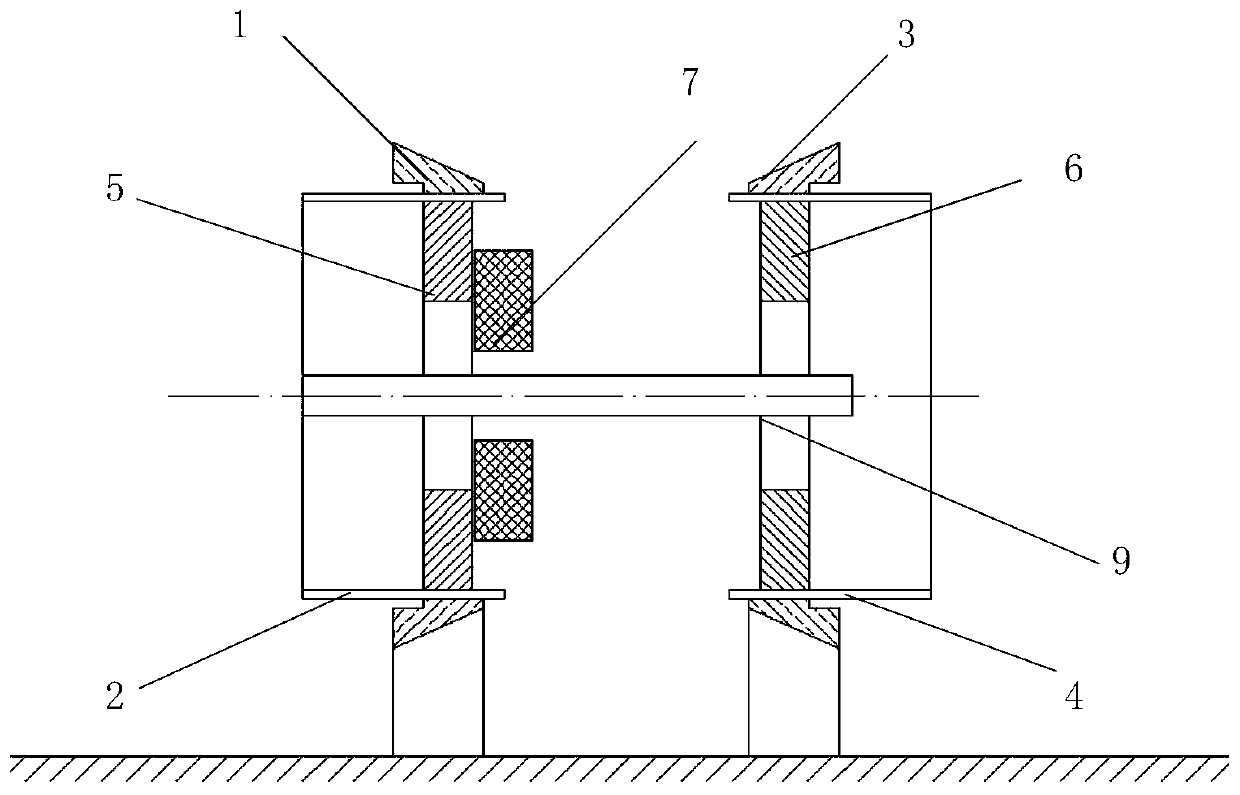

[0078] The embodiment of the present invention provides a friction stir welding method for rocket tank assembly, such as Figure 13 As shown, the rocket tank assembly includes a rear bottom section 12, a front bottom section 13, and a plurality of barrel sections 14 between the front bottom section 13 and the rear bottom section 12, and the barrel section 14 is made of aluminum alloy; Next, take the friction stir welding of two storage tank sections 14 (i.e. the first hollow column member 2 and the second hollow column member 4) as an example, and the friction stir welding method is explained as follows:

[0079] The outer radius R1, inner radius R2 and axial length d of the first hollow column member 2 and the second hollow column member 4 are the same, the outer radius is R1, the inner radius is R2, and the outer pressing mechanism is composed of a base and a pressing part , the base and the pressing part are fastened together to form a hollow structure, the cross section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com