A hanging rubber tapping device and a mechanized rubber tapping method

A hanging, rubber tapping technology, applied in agriculture, forestry, application, etc., can solve the problems of increasing the manufacturing and maintenance costs of automatic rubber tapping machines, and achieve the effect of improving operation smoothness, ensuring reliability, and reducing manufacturing and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in conjunction with accompanying drawing.

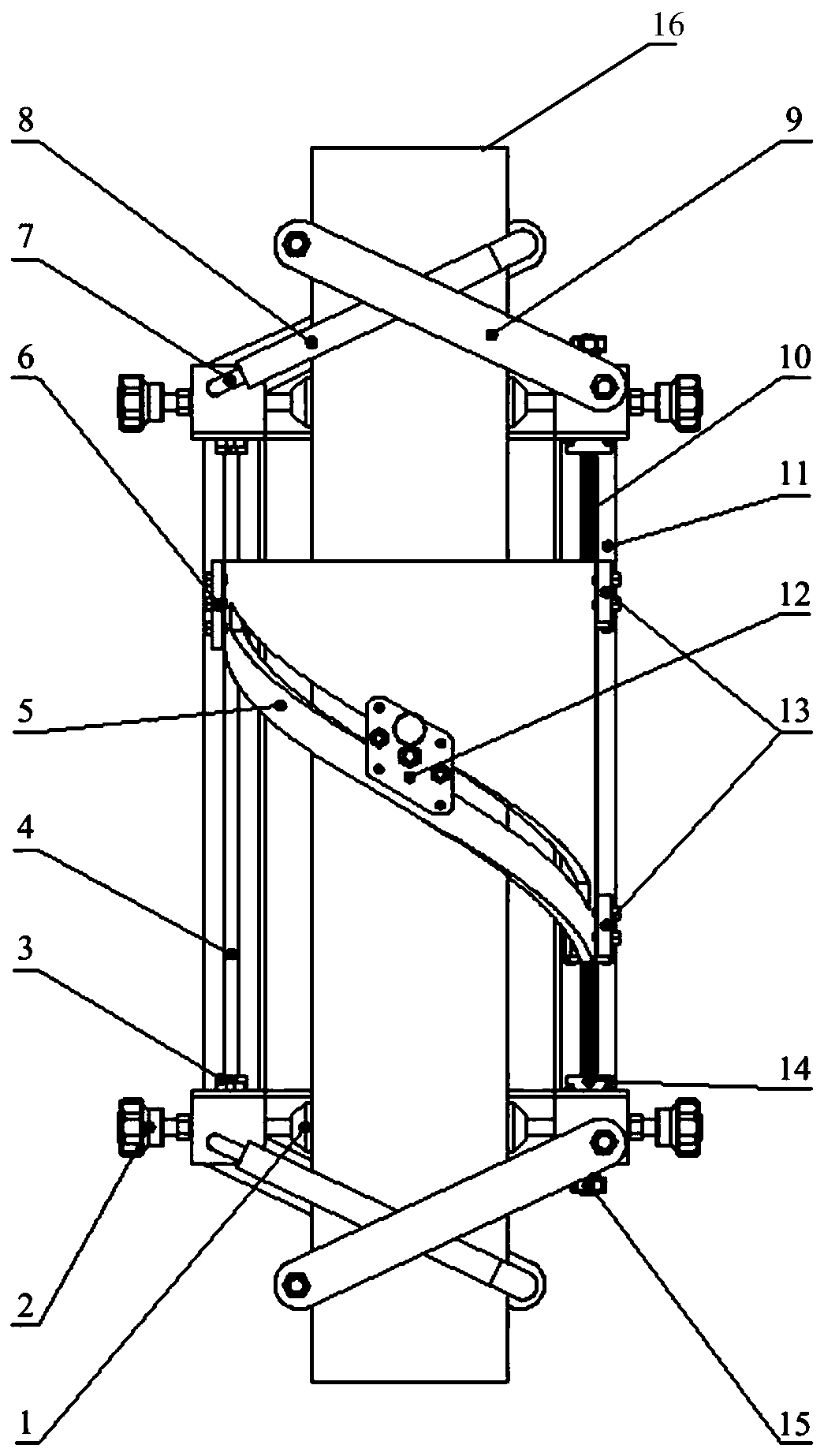

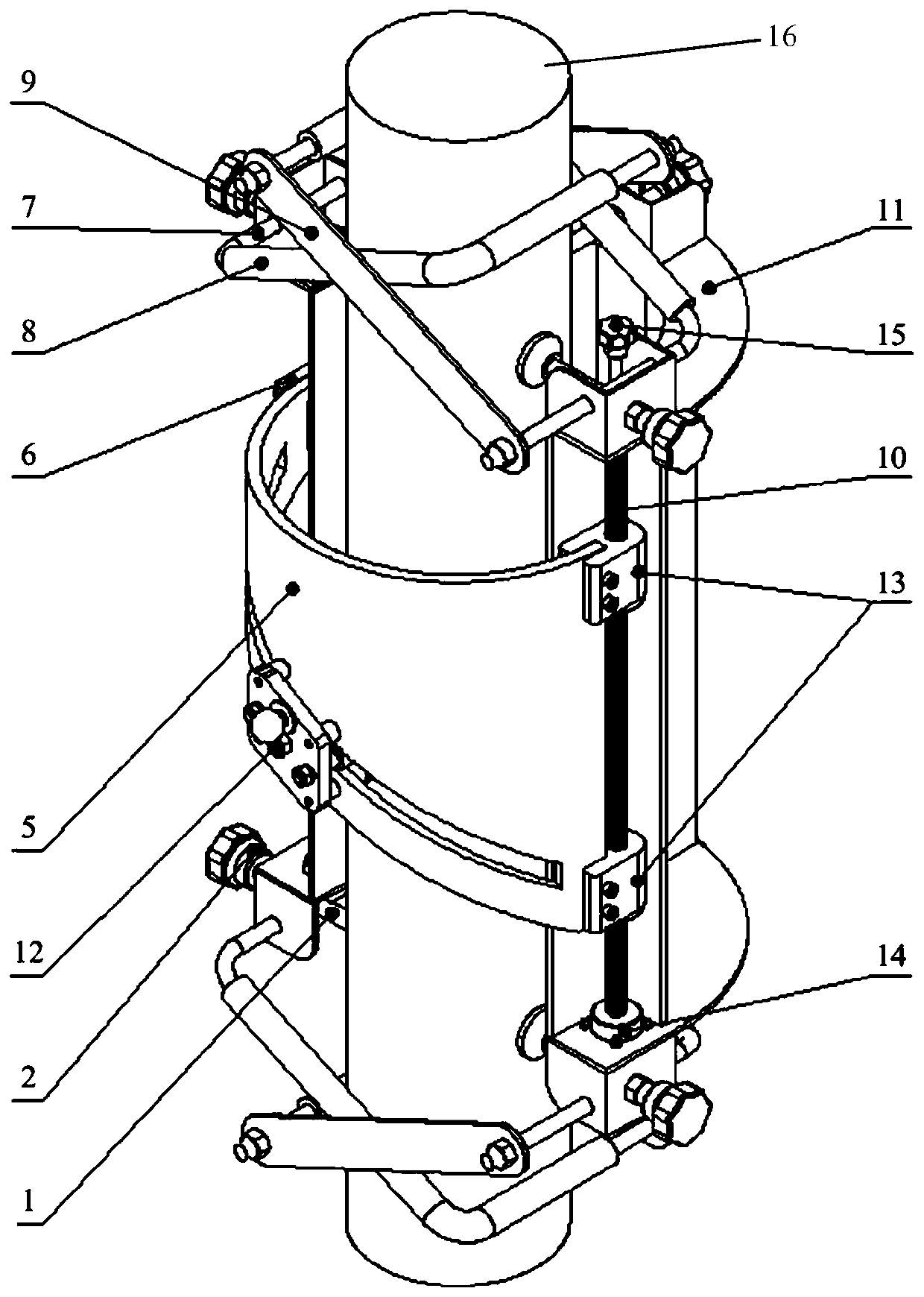

[0072] Such as Figure 1-7 As shown, a hanging rubber tapping device of the present invention includes a tree hugging device, a spiral forming guide device and a sliding seat 12 . in,

[0073] The tree-hugging device includes a frame 11, a hoof 1, a first knob 2, a hoop 7, a rubber tube 8 and a pressing plate 9.

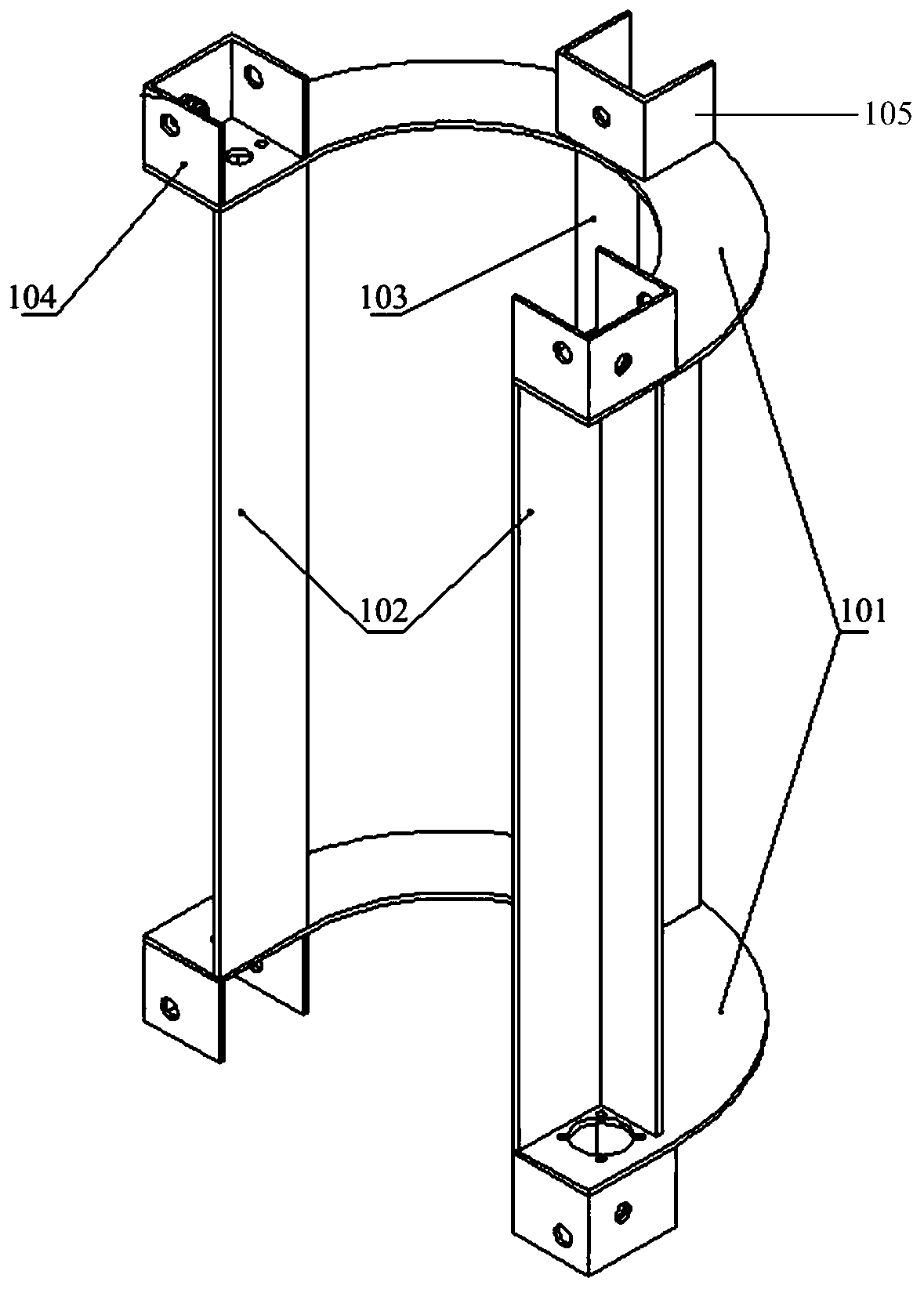

[0074] Such as image 3 As shown, the frame 11 is a column structure, and the upper and lower ends are frame plates 101, and the frame plate 101 is "U" shaped. The two frame plates 101 at the upper and lower ends are fixedly connected by a first support plate 102 and a second support plate 103 . The first support plate 102 is preferably "L" shaped with an inner space; the second support plate 103 is preferably "U" shaped. The first support plate 102 connects the corresponding ends of the two frame plates 101 at the upper and lower ends, and the second support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com