Test platform for drop hammer tester and drop hammer test method

A test platform, drop weight test technology, applied in the testing of machine/structural components, impact testing, measuring devices, etc., can solve the problem of difficulty in accurately measuring the impact force of the test piece, save workload, improve sensitivity, and widely The effect of generality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

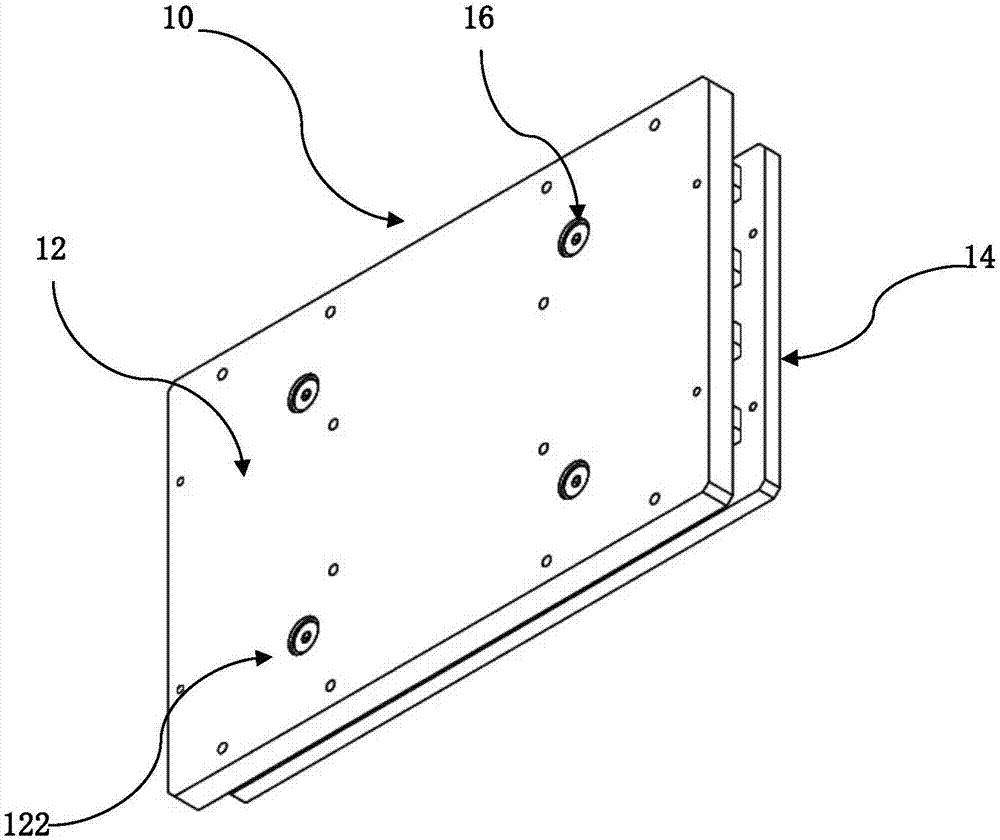

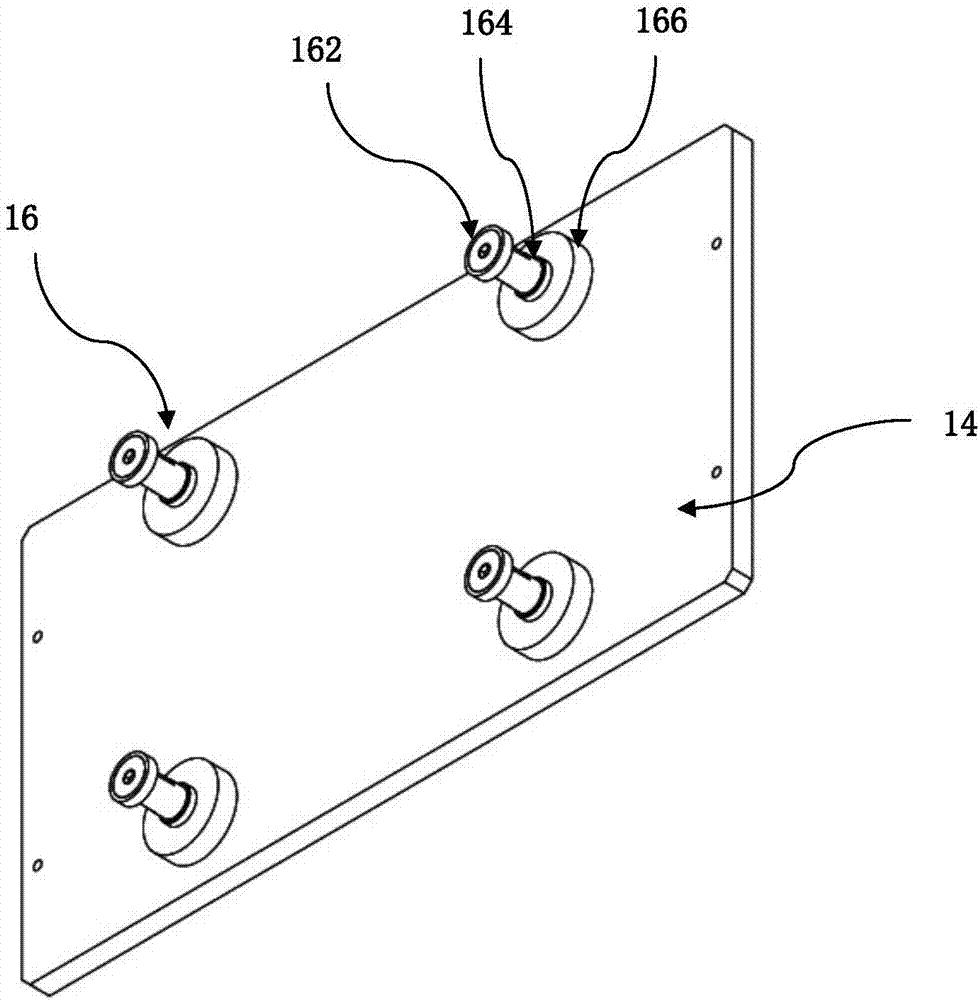

[0026] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

[0027] It should be noted that the same reference numerals in the specification and claims of the present invention and the above drawings refer to the same components, and the terms "first", "second", etc. are used to distinguish similar objects, but not necessarily used for Describe a specific order or sequence. It is to be understood that the terms so used are interchangeable under appropriate circumstances in order to describe the embodiments of the invention herein. Furthermore, the terms "comprising" and "having", as well as any variations thereof, are intended to cover a non-exclusive inclusion, for example, a process, method,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com