Self-locking tool car

A tool car, self-locking technology, applied in the direction of manufacturing tools, workshop equipment, etc., can solve the problem that the drawer cannot be locked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

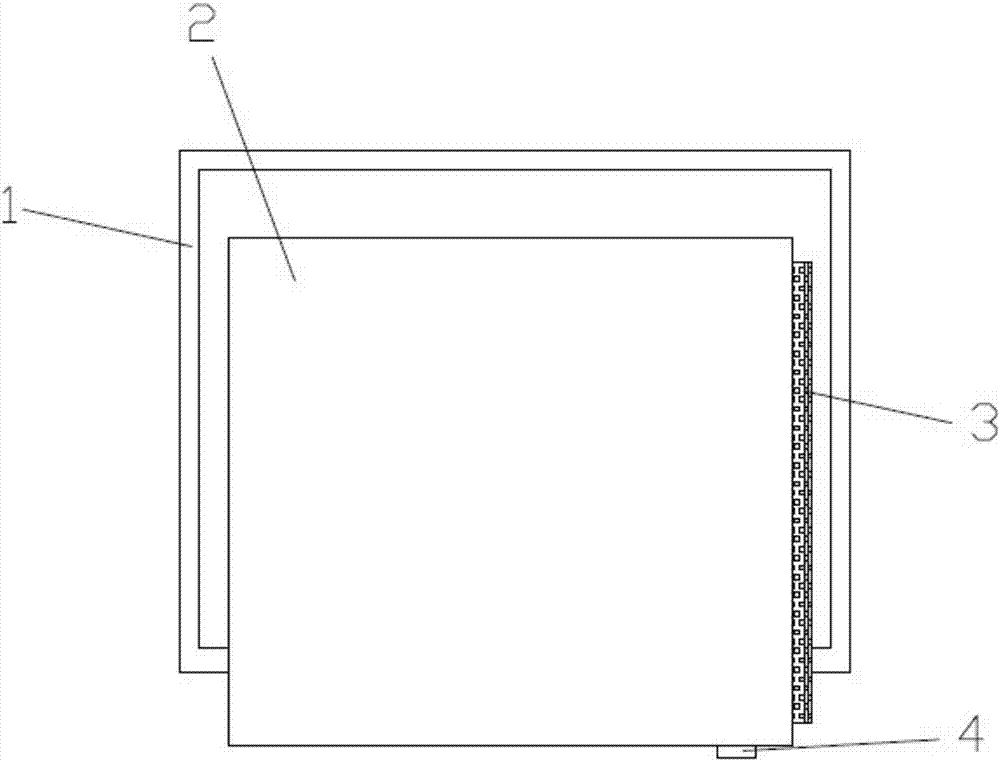

[0009] The embodiment of the self-locking tool cart of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] A self-locking tool trolley, comprising a tool trolley frame and a drawer arranged in the tool trolley frame, the side of the drawer is provided with a strong electromagnet 3 arranged along the length direction of the side and equal in length to it, and the top of the drawer faces the outside of the tool trolley frame A magnet switch 4 is arranged on the surface, the tool cart frame is a steel tool cart frame 1, and the drawer is a high-strength plastic drawer 2. During use, that is, when the high-strength plastic drawer 2 is partially pulled out of the steel tool cart frame 1, press the magnet switch 4 to start the strong electromagnet 3, and the strong magnetic force will firmly connect the strong electromagnet 3 to the steel tool cart frame 1. stick together.

[0011] The above is only a preferred embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com