Temperature adaptive ferrite switch driver

A technology of switch driver and switch drive circuit, which is applied in waveguide-type devices, pulse train generators, pulse generators, etc., can solve the problems of poor compensation accuracy, actual temperature deviation, affecting the performance indicators of ferrite switches, etc., and achieves improved bandwidth. Temperature performance indicators, the effect of temperature adaptive control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

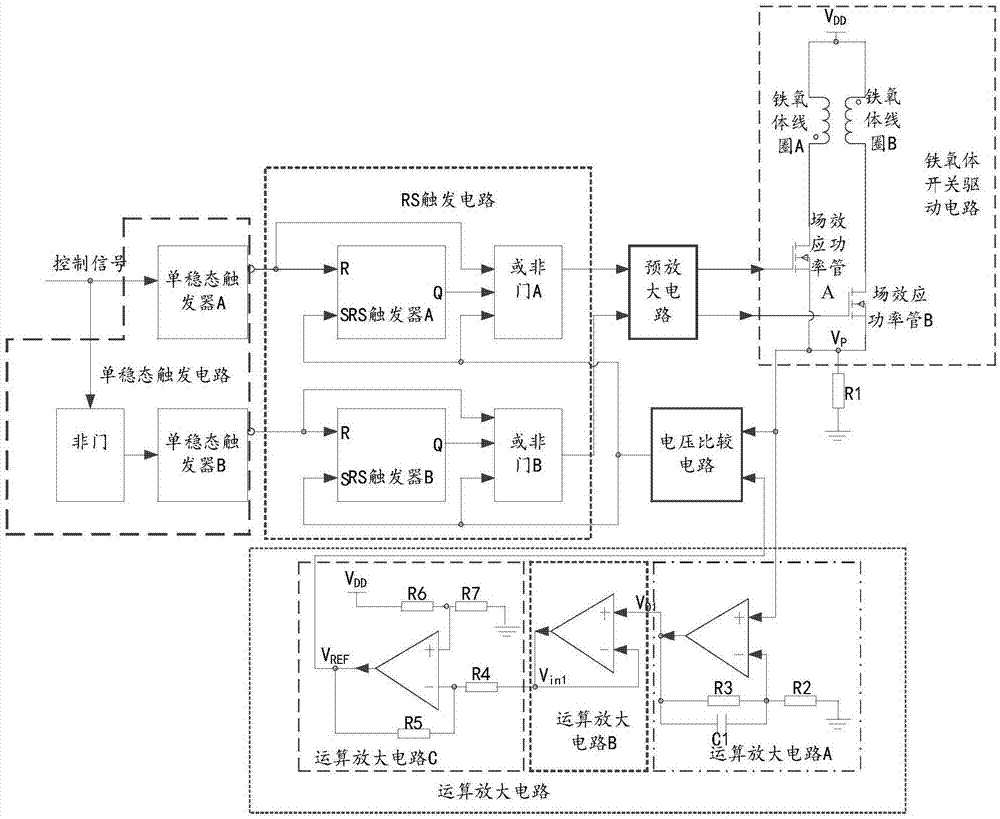

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

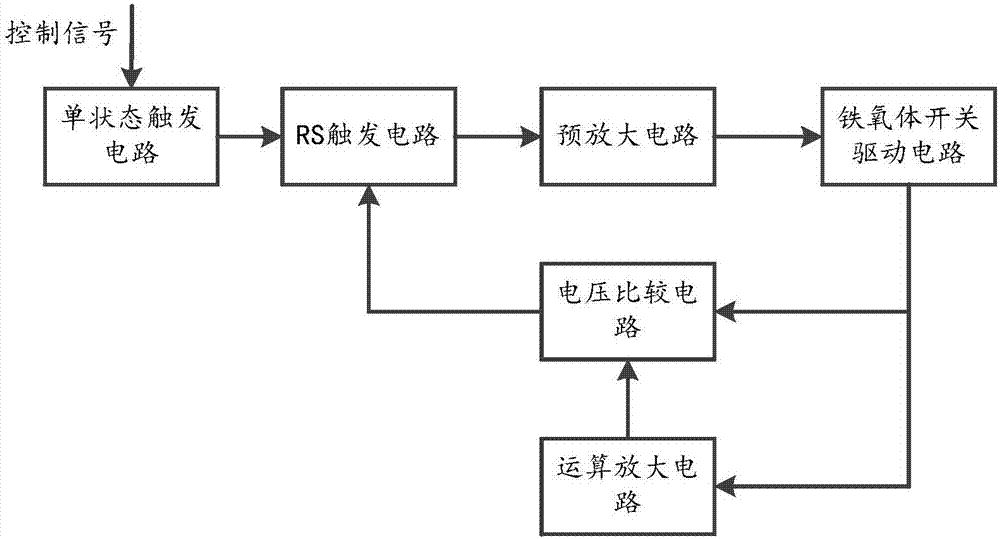

[0039] figure 1 It is a structural schematic diagram of a temperature-adaptive ferrite switch driver of the present invention.

[0040] Such as figure 1 As shown, Embodiment 1 is a temperature-adaptive ferrite switch driver, which includes: a single-state trigger circuit, an RS trigger circuit, a pre-amplification circuit, a voltage comparison circuit, and a ferrite switch driver circuit, operational amplifier circuit;

[0041] The single-state trigger circuit is used to output a negative pulse signal according to the state of the control signal;

[0042] The RS trigger circuit is used to output a high-level signal according to the negative pulse signal;

[0043] The pre-amplification circuit is used to amplify ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com