Motor assembly

A technology of motor components and components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

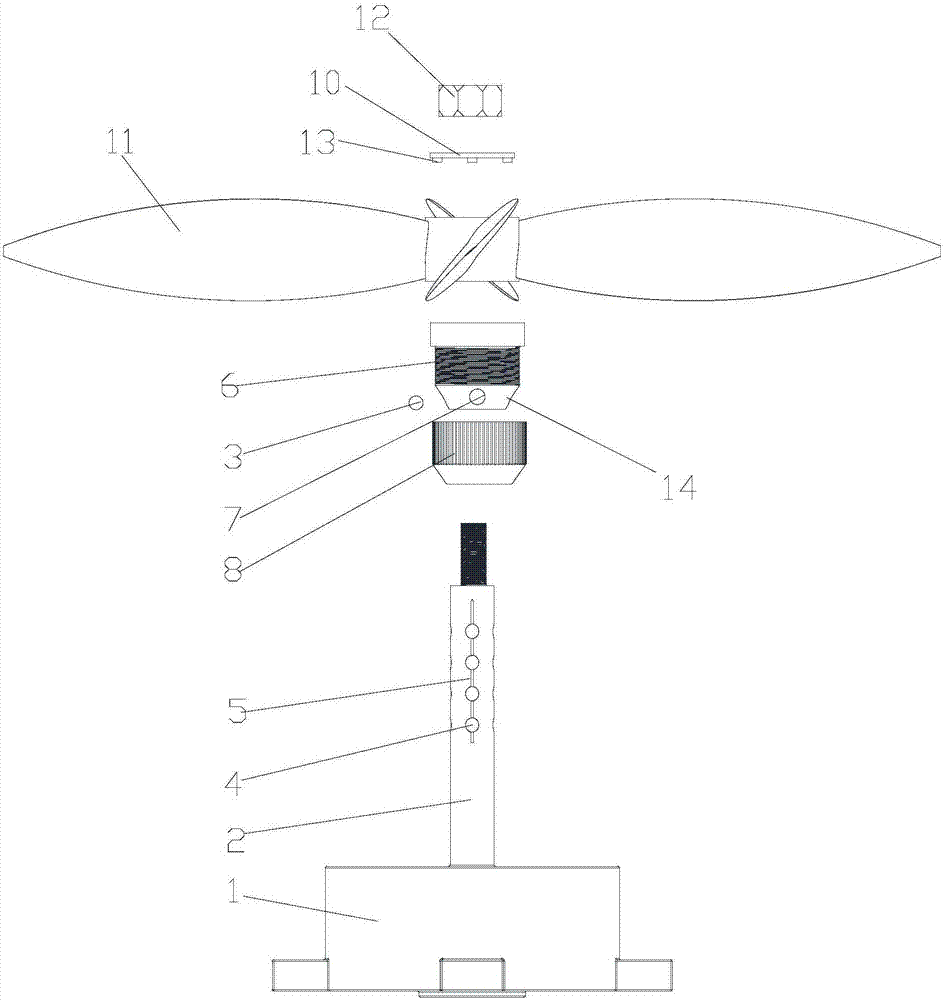

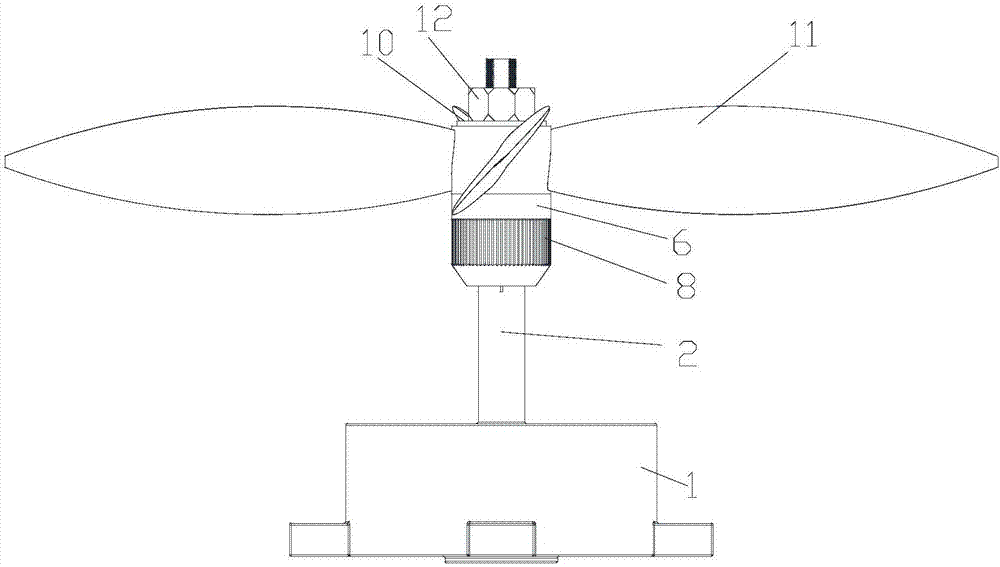

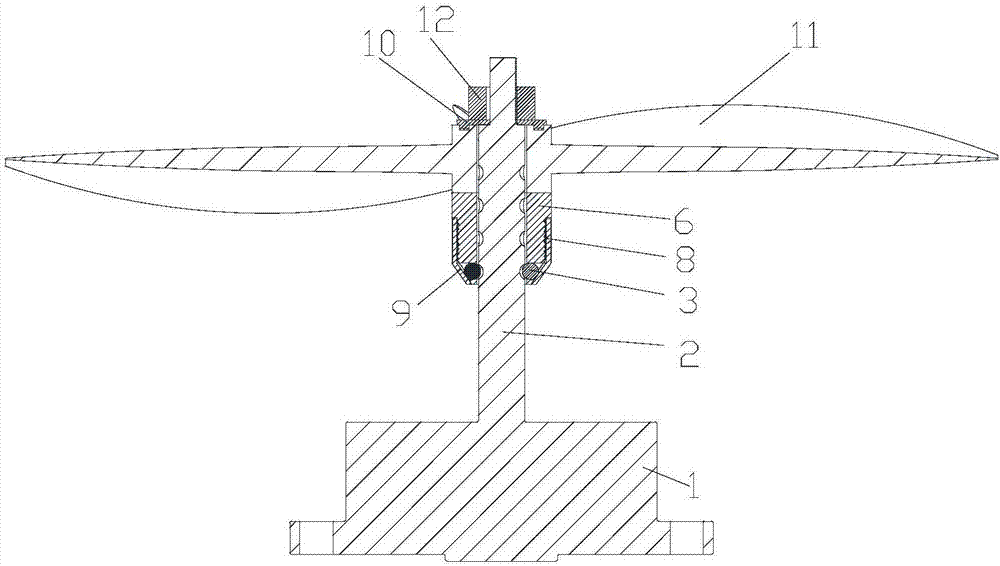

[0034] see in conjunction Figure 1 to Figure 7 As shown, according to the embodiment of the present invention, the motor assembly includes a motor body 1 and an axial positioning assembly; the motor body 1 has a motor shaft 2 , and the axial positioning assembly is used to adjust the axial installation position of components on the motor shaft 2 .

[0035] Since the axial positioning component can adjust the axial installation position of components such as the fan blade 11 on the motor shaft 2, it can be applied to the installation of fan blades 11 of different specifications, and can meet the requirements of different users on the fan blade 11 on the motor shaft 2. The installation position requirements are met, the axial adjustability of the motor shaft 2 and the fan blade 11 is realized, and the versatility of the motor is improved.

[0036] Preferably, the axial positioning assembly is movably arranged along the axial direction of the motor shaft 2, and the axial positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com