Diffractive optical element and preparation method

A technology of diffractive optical elements and light sources, applied in optical elements, optics, instruments, etc., can solve problems such as reducing the uniformity of speckle patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

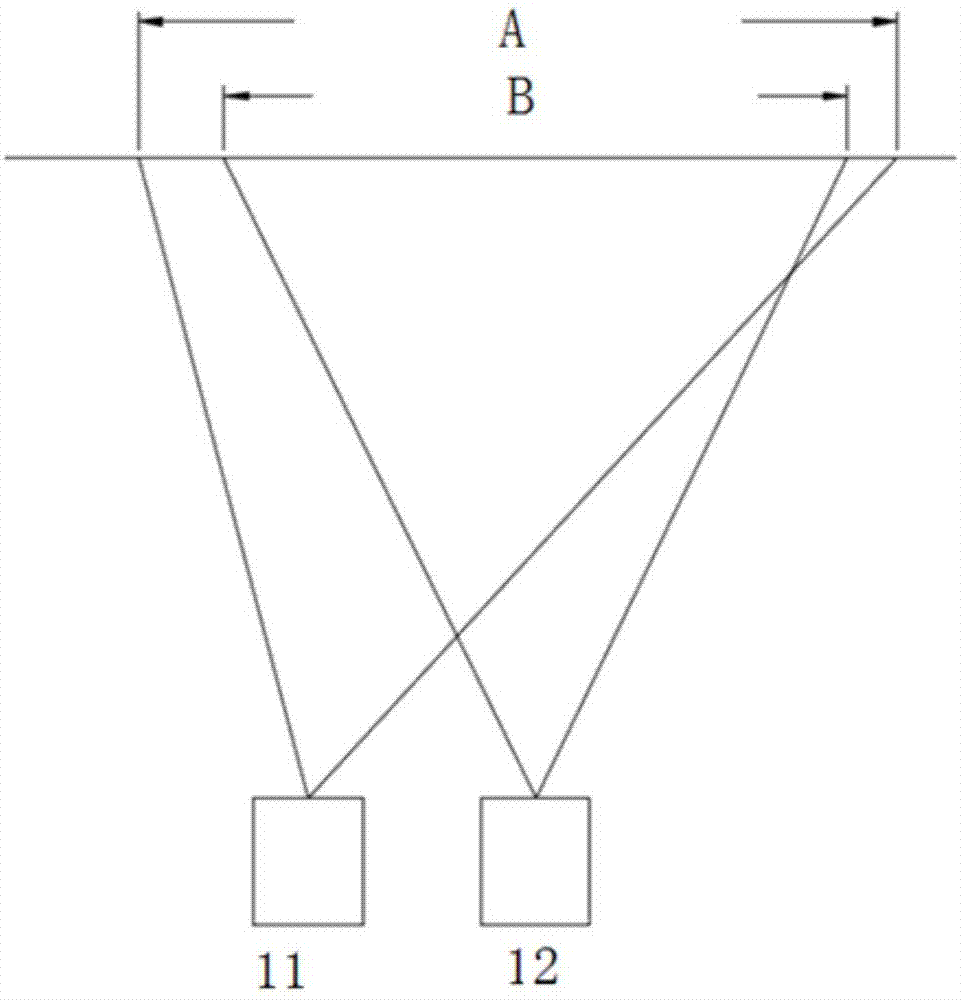

[0047] figure 1 It is a schematic diagram of a depth camera based on structured light technology. The depth camera includes a structured light projection module 11 and an acquisition module 12. The structured light projection module is used to project structured light patterns into the spatial projection area A, and the acquisition module is used to acquire structured light images on objects in its acquisition area B , generally the projection area A is not lower than the collection area B, so as to ensure that the objects in the collection area corresponding to the collection module can be covered by the structured light pattern. In addition, the depth camera also includes a processor for receiving the structured light image collected by the collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com