All-closed nuclear drum vacuum valve main shaft sealing structure

A fully-enclosed, spindle-sealing technology, which is applied to engine seals, engine components, mechanical equipment, etc., can solve problems that cannot meet the needs of large-diameter drum seals, and achieve the effect of safe and reliable sealing structure and optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

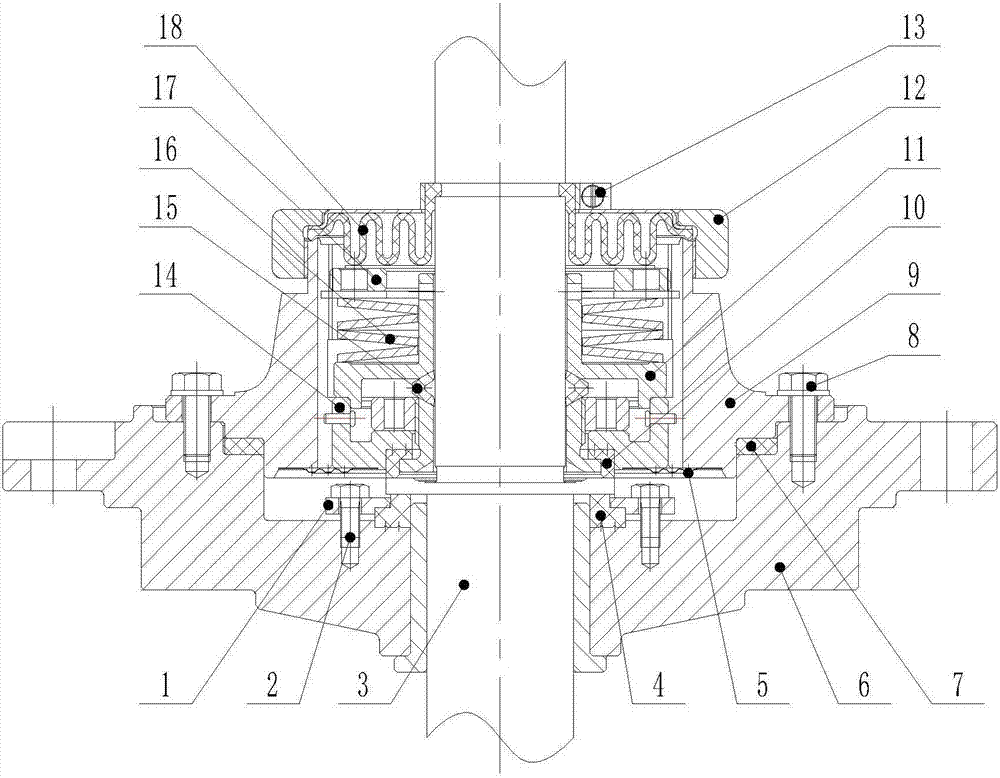

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 As shown, the fully enclosed nuclear drum vacuum valve spindle sealing structure of the present invention includes, bolt A2, lower sealing ring 4, diaphragm 5, sealing ring 7, bolt B8, upper sealing ring 10, and a large nut 12. Clamp 13, lip seal ring 15, matching disc spring group 16, nut 17, rubber bowl 18;

[0014] The lower sealing ring 4 is fixed between the pressure plate 1 and the assembly cover 6 by the bolt A2; the sealing ring 7 is fixed between the shell 9 and the assembly cover 6 by the bolt B8; the main shaft 3 is pressed on the lower sealing ring 4; Pressure welding, connecting the shell 9 and the support 14; the upper sealing ring 10 is installed between the support 14 and the main shaft 3; the lip seal ring 15 is installed between the sleeve 11 and the main shaft 3; On the top of the sleeve 11; the nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com