Smearing actuator

A technology of actuators and coatings, applied in the direction of architecture and building structure, etc., can solve the problems of inability to complete the application of equipment and limited application scope, and achieve the effect of good application quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

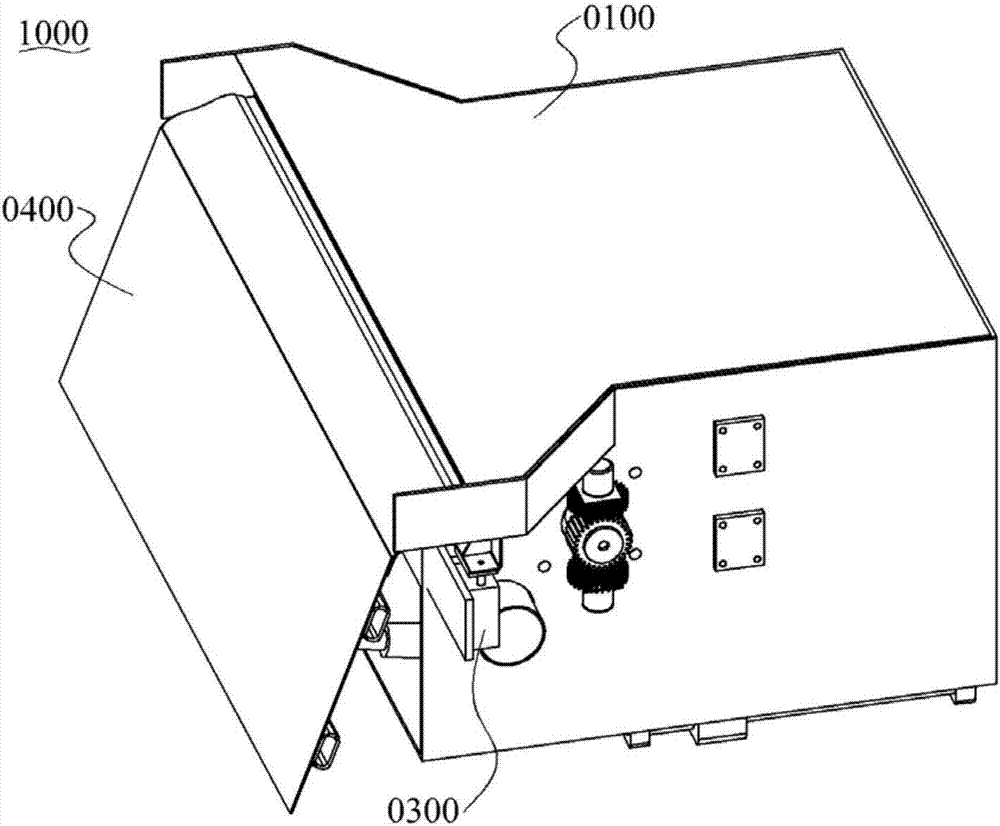

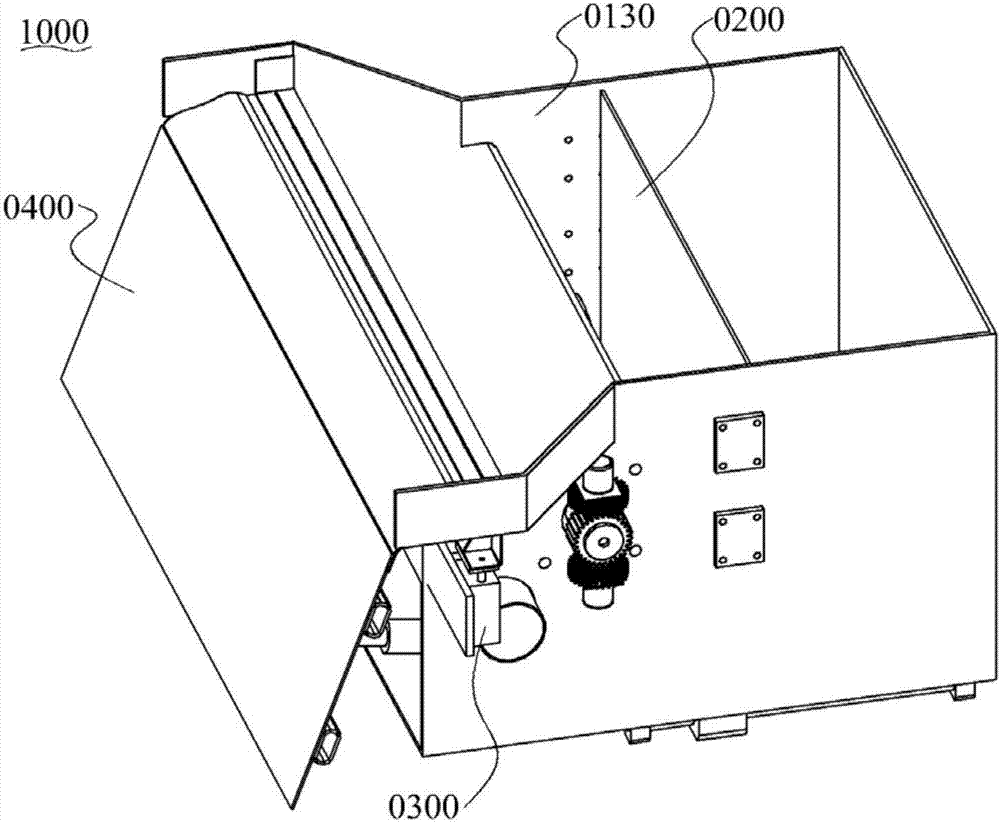

[0043] Please refer to Figure 1~5The smearing actuator 1000 has a material storage unit 0100 for storing paint, and has a material inlet 0110 and a material outlet 0120, the material inlet 0110 is used for inputting paint, and the material outlet 0120 is used for outputting paint.

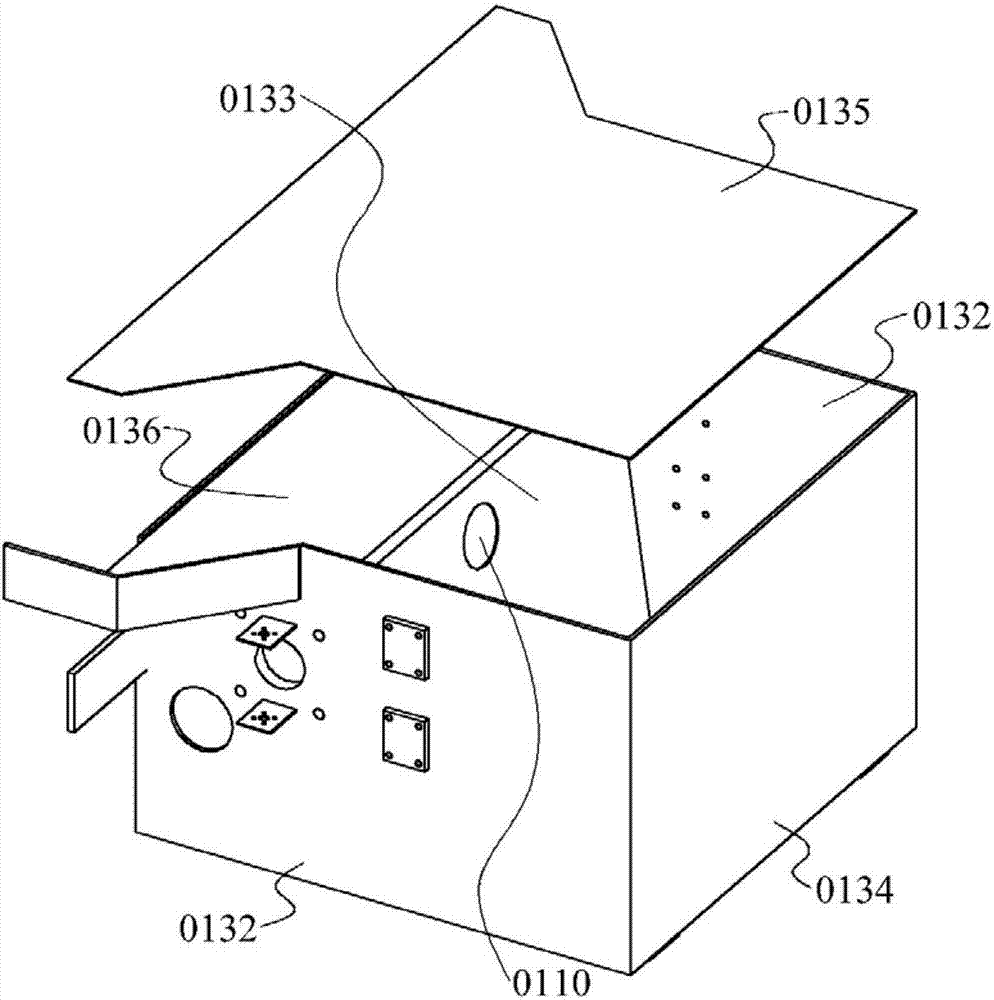

[0044] Specifically, the storage unit 0100 may adopt structural forms such as a hopper and a box. According to actual needs, the storage unit 0100 can have a closed box structure or an open hopper structure. In this embodiment, the storage unit 0100 has a housing 0130 with a closed box structure, and the housing 0130 has a bottom plate 0131 , side plates 0132 , front sealing plate 0133 , rear sealing plate 0134 and top plate 0135 . Wherein, the front sealing plate 0133 is located in the middle of the bottom plate 0131, surrounded by the bottom plate 0131, side plates 0132, front sealing plate 0133 and rear sealing plate 0134 to form a hopper for containing paint, and is closed from the top by the...

Embodiment 2

[0074] This embodiment and embodiment 1 belong to different implementation modes of the same scheme, and have the same structural layout. Only the differences between the two will be described in detail below, and the similarities will not be repeated.

[0075] see Figure 6~7 , the storage unit 0100 has a housing 0130, the housing 0130 has a side plate 0132, a rear sealing plate 0134 and a top plate 0135, the top plate 0135 is provided with a feed port 0110 for inputting paint, the top plate 0135, the side plate 0132 and the feeding mechanism 0200 surrounds and forms the discharge port 0120 for outputting paint.

[0076] The conveying mechanism 0200 includes a conveyor belt 0230. Specifically, the conveyor belt 0230 includes a driving roller, a driven roller, and a conveyor belt 0230 tensioned to connect the driving roller and the driven roller. The conveyor belt 0230 rotates continuously to convey the coating. Wherein, the upper surface of the conveyor belt 0230 is a mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com