Multilevel structure titanium dioxide nanowire array and preparation method thereof

A technology of nanowire array and titanium dioxide, which is applied in the field of nanomaterials and can solve problems affecting applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

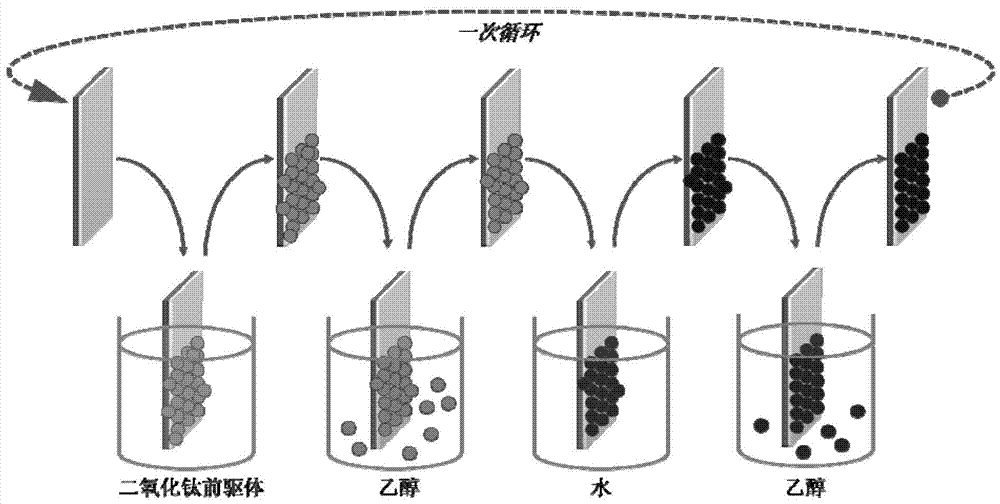

Method used

Image

Examples

preparation example Construction

[0051] Preparation of TiO2 seed layer

[0052] The substrate is soaked in the solution containing the titanium source for a period of time. Titanium source can be titanium salt, titanate. In one example, the titanium source is TiCl 4 . The concentration of the titanium source in the solution containing the titanium source may be 0.01-0.10M. The temperature of the heat preservation may be 50-120°C (for example, 70°C). The heat preservation time can be 10-60 minutes. After dipping, the substrate is taken out and heat-treated, for example, placed in a tube furnace at 450-550° C. for 30-120 minutes to obtain a titanium dioxide seed layer. The titanium dioxide seed layer may have a thickness of about 5-30 nm.

[0053] Hydrothermal Synthesis of TiO Single Crystal Nanowire Arrays

[0054] The substrate formed with the titanium dioxide seed crystal layer is placed in a hydrothermal precursor solution for hydrothermal reaction to attach a titanium dioxide single crystal nanowire...

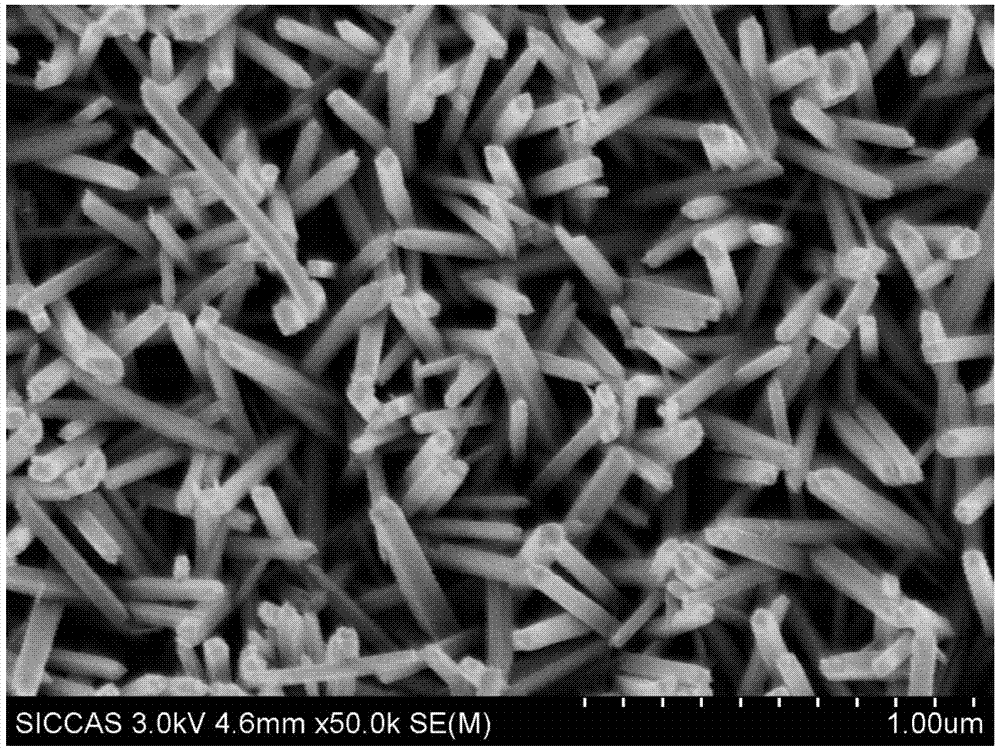

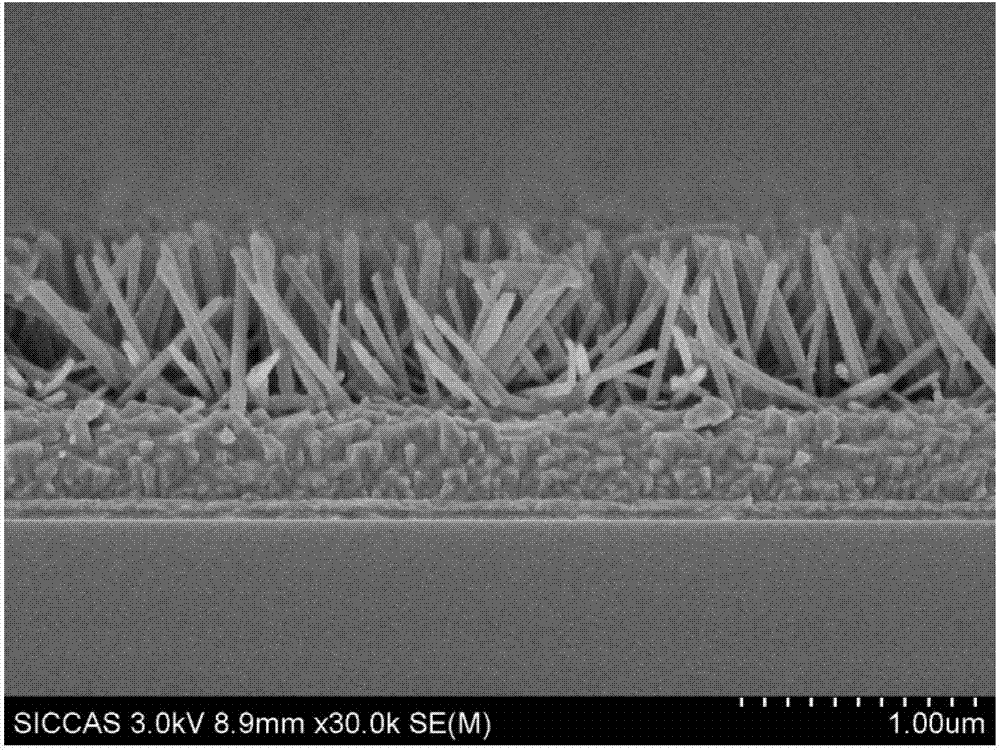

Embodiment 1

[0069] (1) The FTO transparent conductive glass was ultrasonically cleaned in acetone, ethanol and deionized water for 15 minutes, and then dried in an oven at 60°C for 2 hours.

[0070] (2) Dip the cleaned FTO transparent conductive glass in 0.06M TiCl 4 , heated in a water bath to 70°C for 30 minutes, took it out and placed it in a tube furnace for heat treatment at 450°C for 30 minutes to obtain a titanium dioxide seed layer.

[0071] (3) 15 mL of deionized water, 15 mL of concentrated hydrochloric acid (38% by mass) and 0.375 mL of tetrabutyl titanate were measured respectively, and magnetically stirred for 15 minutes.

[0072] (4) Take the FTO transparent conductive glass containing the titanium dioxide seed layer and place it obliquely in a 50mL polytetrafluoroethylene digestion tank so that the transparent conductive layer is placed downward. Then the precursor solution in step (3) is transferred into a polytetrafluoroethylene digestion tank. Move the polytetrafluoroeth...

Embodiment 2

[0076] (1) The FTO transparent conductive glass was ultrasonically cleaned in acetone, ethanol and deionized water for 15 minutes, and then dried in an oven at 60°C for 2 hours.

[0077] (2) Dip the cleaned FTO transparent conductive glass in 0.06M TiCl 4 , heated in a water bath to 70°C for 30 minutes, took it out and placed it in a tube furnace for heat treatment at 450°C for 30 minutes to obtain a titanium dioxide seed layer.

[0078] (3) 15 mL of deionized water, 15 mL of concentrated hydrochloric acid (38% by mass) and 0.375 mL of tetrabutyl titanate were measured respectively, and magnetically stirred for 15 minutes.

[0079] (4) Take the FTO transparent conductive glass containing the titanium dioxide seed layer and place it obliquely in a 50mL polytetrafluoroethylene digestion tank so that the transparent conductive layer is placed downward. Then the precursor solution in step (3) is transferred into a polytetrafluoroethylene digestion tank. Move the polytetrafluoroe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com