Automobile die with temperature controlling function

A technology for automotive molds and temperature control, applied in the direction of non-rotational vibration suppression, etc., can solve the problems of difficult collection and reuse of melt, gas-liquid mixture equipment pollution, and affecting the quality of molds, so as to achieve high quality, prevent condensation, and reduce heat The effect of the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

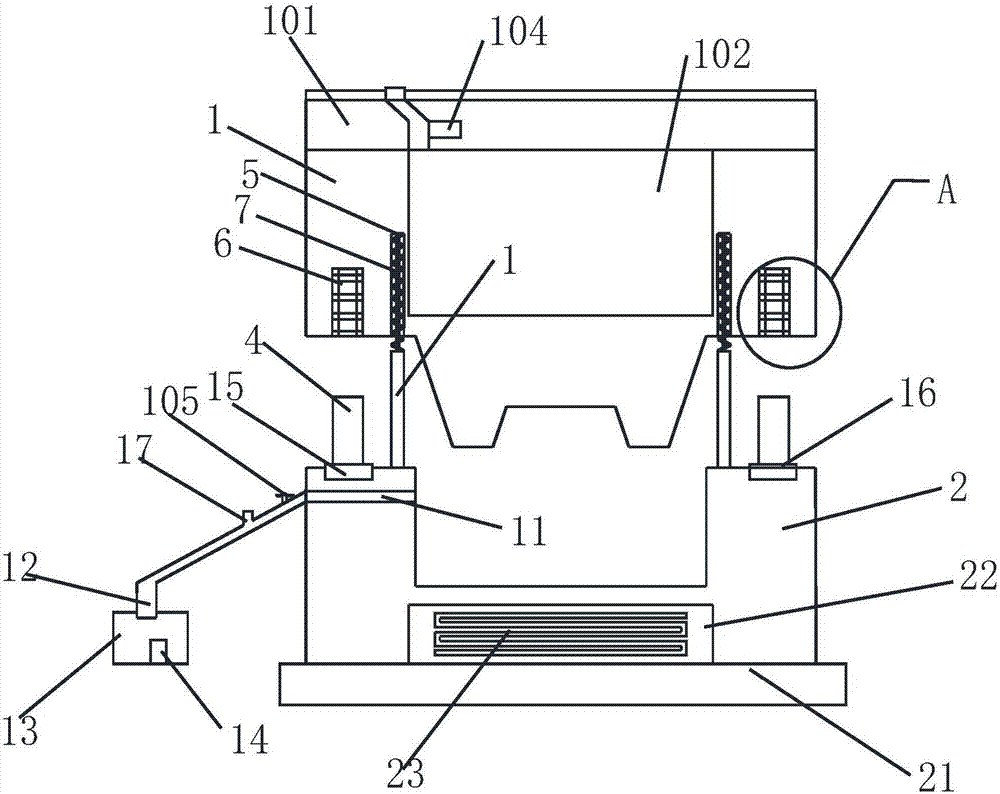

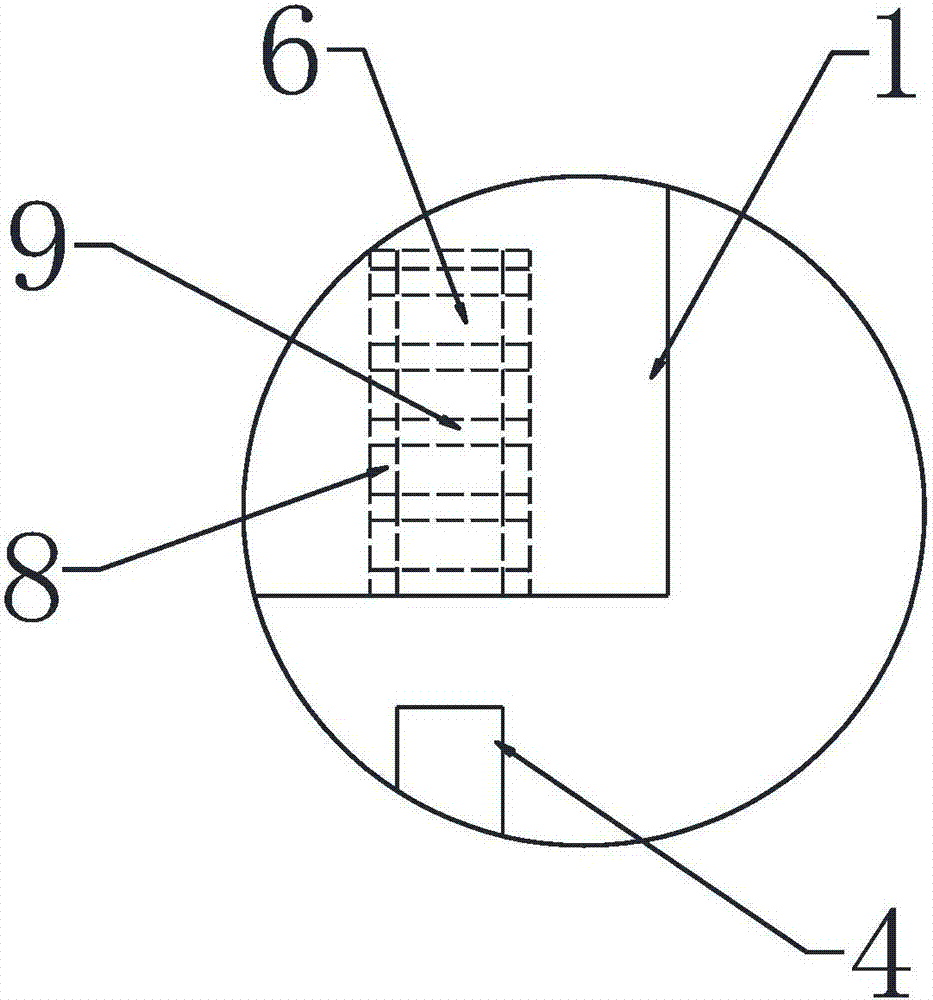

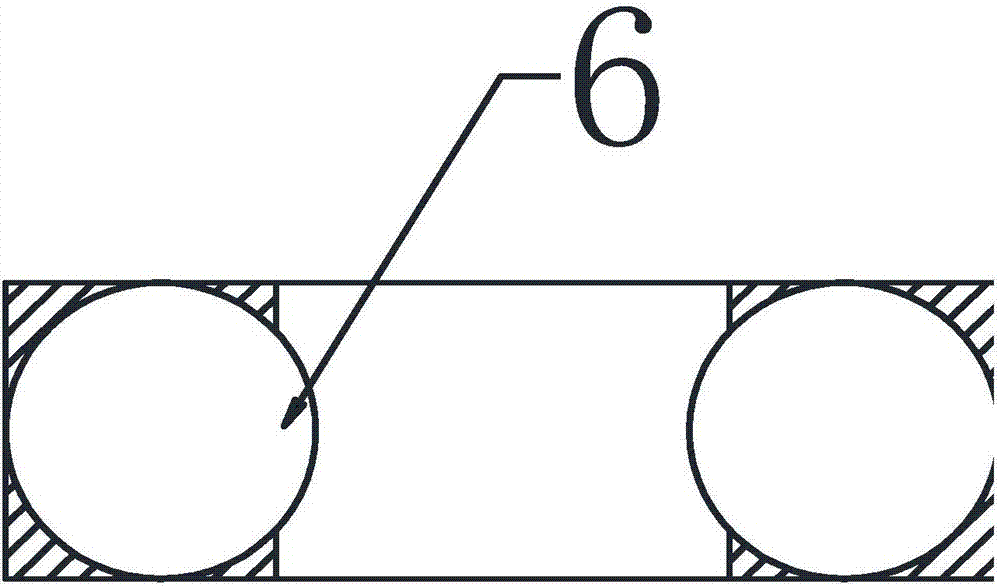

[0026] refer to figure 1 — image 3 , the present invention provides an automobile mold with a temperature control function, comprising an upper template 1 and a lower template 2, the upper template 1 includes an upper mounting seat 101, an upper mold core 102, and the lower template 2 includes a lower mounting seat 21, The lower mold core 22, the upper surface of the upper mounting seat 11 is equipped with an upper top plate, the upper top plate is provided with a sprue, the gate is connected to the feeding channel, and the feeding channel passes through the upper mounting seat 101 is connected with the upper mold core 102; the upper mold core 102 is fixedly installed in the upper mounting seat 101 by bolts; the upper mold core 102 and the lower mold core 22 cooperate with each other to form a molding cavity; the lower mold core 102 Installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com