Mechanical ultrasonic type huperzine A extracting device with cleaning machine and carbonization forming machine

A technology of huperzine A and washing machine is applied in the directions of cleaning methods and utensils, solid solvent extraction, chemical instruments and methods, etc., and can solve the problems of low leaching efficiency, difficult separation and extraction of effective components and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

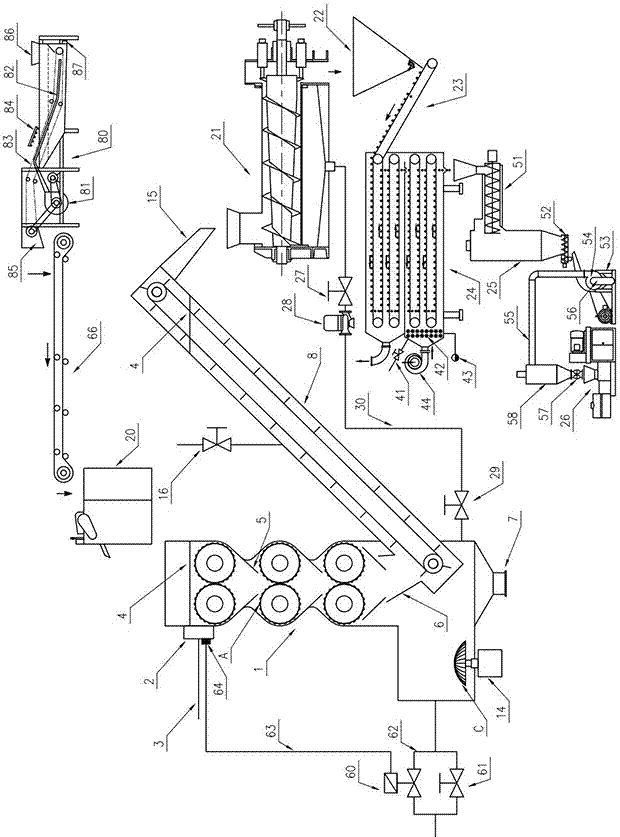

[0031] Now in conjunction with accompanying drawing, the present invention is described in further detail.

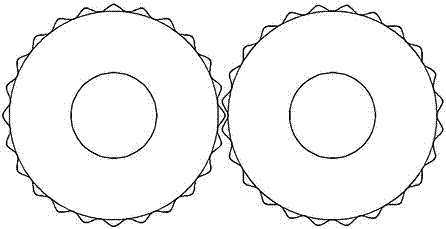

[0032] Such as Figure 1-Figure 7 The mechanical ultrasonic huperzine A leaching device with cleaning machine and charcoal forming machine shown includes a body 1, and is characterized in that: the cleaning machine discharge port 85 of the bubble cleaning machine 80 passes through the Melaleuca tower conveyor 66 and the cutting machine. The feed port of the shredder 20 is connected, and a machine body 1 is provided below the discharge port of the shredder 20, and a three-stage counter-rotating spline curve roller A is arranged inside the machine body 1, and the surface of the counter-rotating spline curve roller A is a continuous spline surface , the bottom of each counter-rotating spline curve roller A is equipped with a Melaleuca tower guide groove 5, and the last stage guide groove 5 is connected to the hopper 6 of the Melaleuca tower hoist 8, and the discharge troug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com