Production technology of instant porridge powder

A production process and technology of porridge powder, applied in the field of production technology of brewed porridge powder, can solve the problems of lack, taste or taste can not reach porridge, short storage time, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

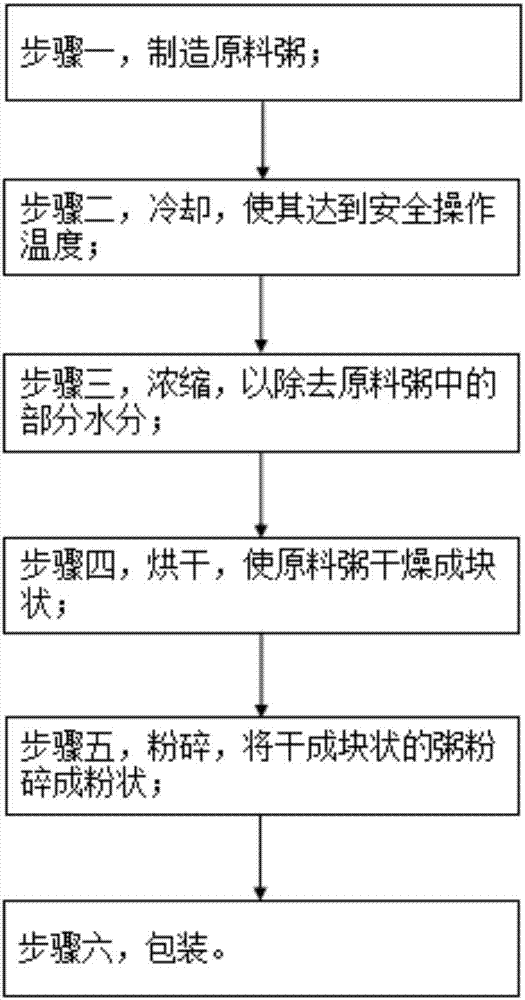

[0027] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0028] refer to figure 1 , the production process of the ready-to-eat porridge powder provided by the invention comprises the following five steps.

[0029] Step 1, making raw porridge.

[0030] In some specific implementations, the raw porridge is produced in the following manner:

[0031] A, raw material pretreatment, including:

[0032] Washing beans and grains can remove particles such as stones mixed in the raw materials, and can also clean the dust attached to the surface of beans and grains;

[0033] After cleaning, it can be dried by standing or blown by blowing equipment, or directly by drying equipment;

[0034] Break the dried beans or / and grains, so that the raw material particles are broken into about 1 / 4 or 1 / 8 of the original particle size, which is convenient for rapid cooking;

[0035] Then s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com