Special thermostatic cartridge and water outlet structure for gas water heater

A technology of gas water heaters and thermostatic valve cores, applied in the field of thermostatic valves, can solve problems such as the temperature cannot be adjusted high, the temperature cannot be lowered, repeated ignition and extinguishing, etc., and achieves the effect of convenient operation, simple structure, and accelerated flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below through specific embodiments.

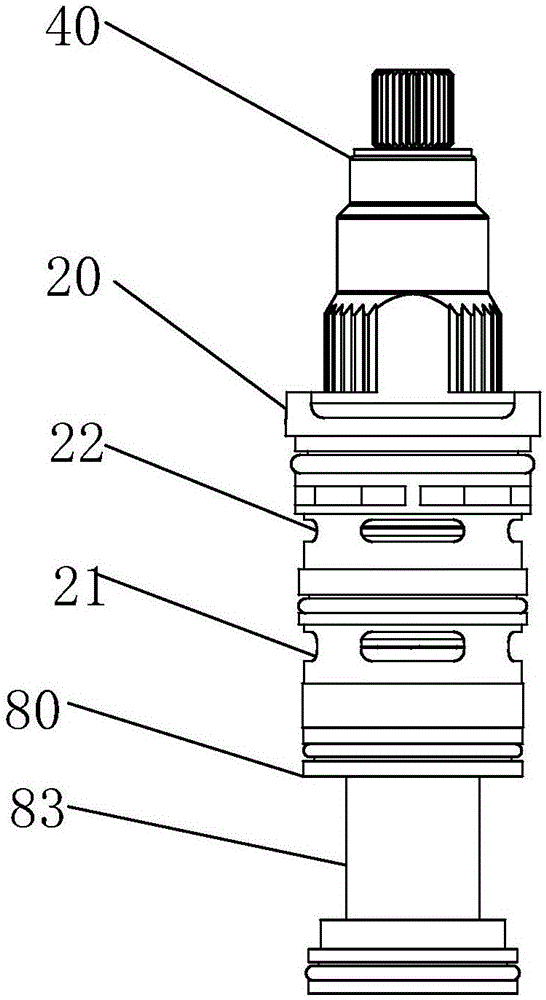

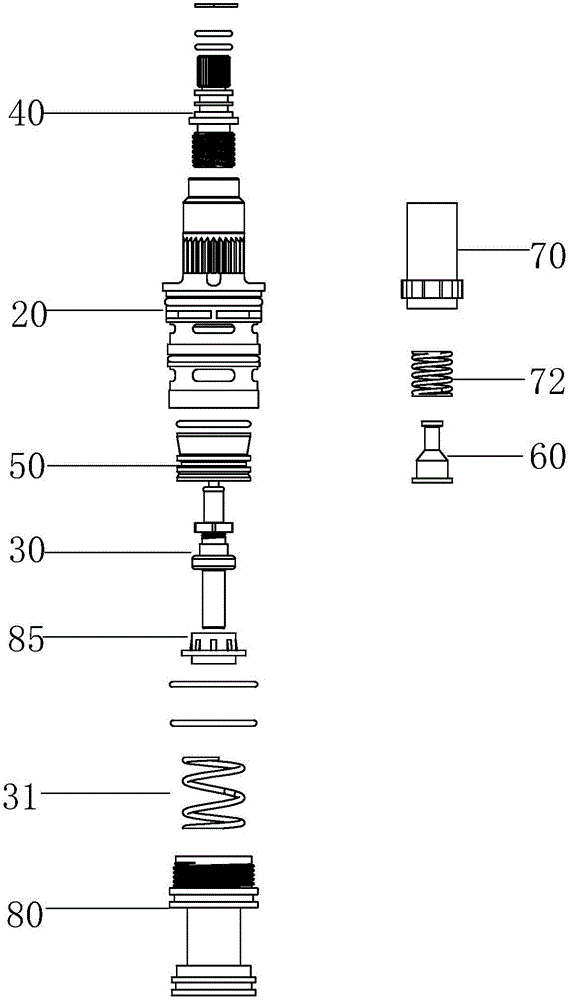

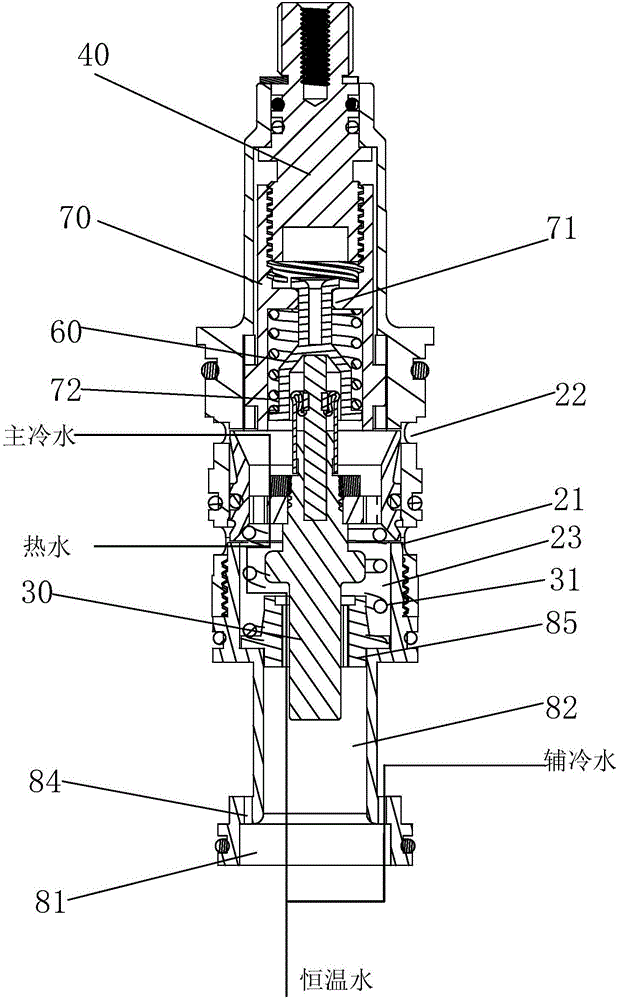

[0031] refer to Figure 1 to Figure 7 , a special thermostatic valve core for gas water heaters, including a valve core body, the valve core body is provided with a housing 20, a temperature sensing element 30, a temperature regulating rod 40, a piston 50, an adjusting sleeve 60, a sliding sleeve 70 and a booster sleeve 80 Wait. The casing 20 is provided with a hot water inlet 21 , a cold water inlet 22 and a water mixing chamber 23 , and the water mixing chamber 23 communicates with the hot water inlet 21 and the cold water inlet 22 . The temperature sensing element 30 is installed in the water mixing chamber 23 of the casing 20, and a piston 50 is fixedly sleeved on it, and the piston 50 is in sealing fit with the inner wall of the casing 20. The temperature inside is elongated or shortened, thereby driving the piston 50 to move to change the flow of water in the hot water inlet ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com