A control system for loading parts on automatic feeding table

A technology of control system and feeding table, which is applied in loading/unloading, transportation and packaging, conveyors, etc., can solve problems affecting the efficiency of feeding, and achieve the effect of simplifying logic judgment, avoiding inaccurate loading, and real-time speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

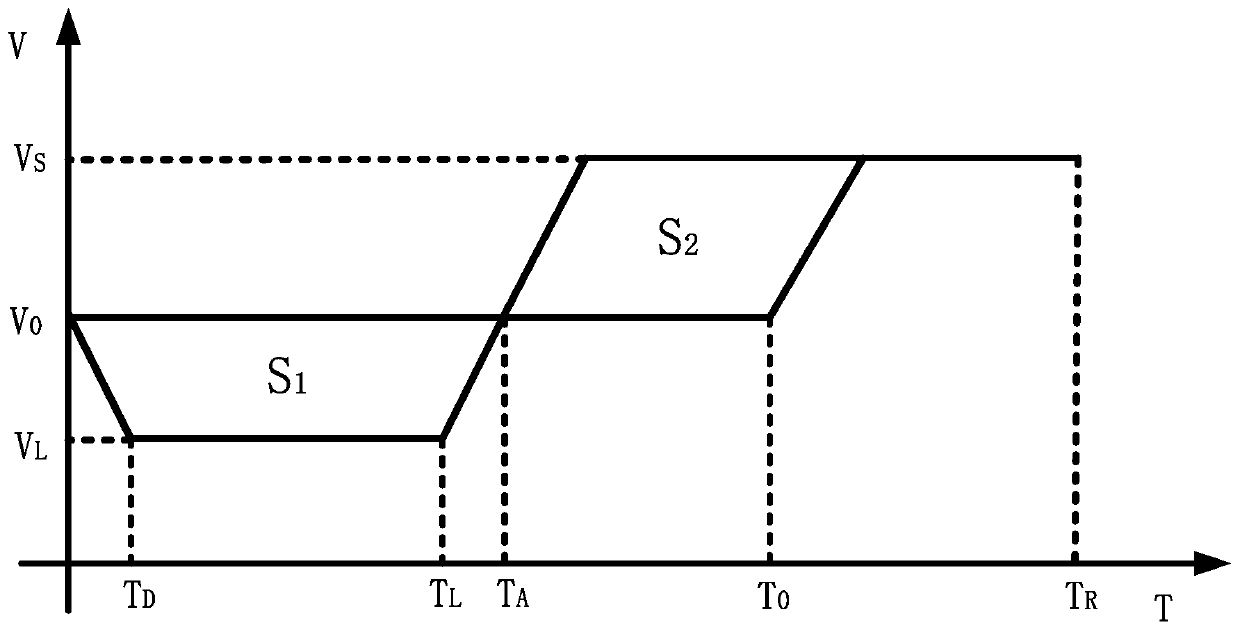

[0062] The adjustment of running parameters mainly involves running speed and running time before acceleration. Since mail ends with V 0 Acceleration starts when the operation is later than the acceleration point, so in order to ensure that the acceleration starts at the acceleration point, the speed at which the mail runs to this point must be less than V 0 . Such as figure 2 As shown, the following relationship can be obtained:

[0063]

[0064] T L ·(V 0 -V L )=(T 0 -T L -T D )·(V S -V 0 ) (4)

[0065]

[0066] V 0 is the normal operating speed of the automatic table, V L is the adjusted operating speed, V S is the synchronous velocity and a is the acceleration. T 0 is V 0 running time, T L is V L run time, including from V 0 Decelerate to V L The running time T D . Equation (1) is the mail by V 0 Decelerate to V L time. Since the total running time is fixed, formula (2) indicates that compared with the running trajectory before adjustment, ...

no. 2 example

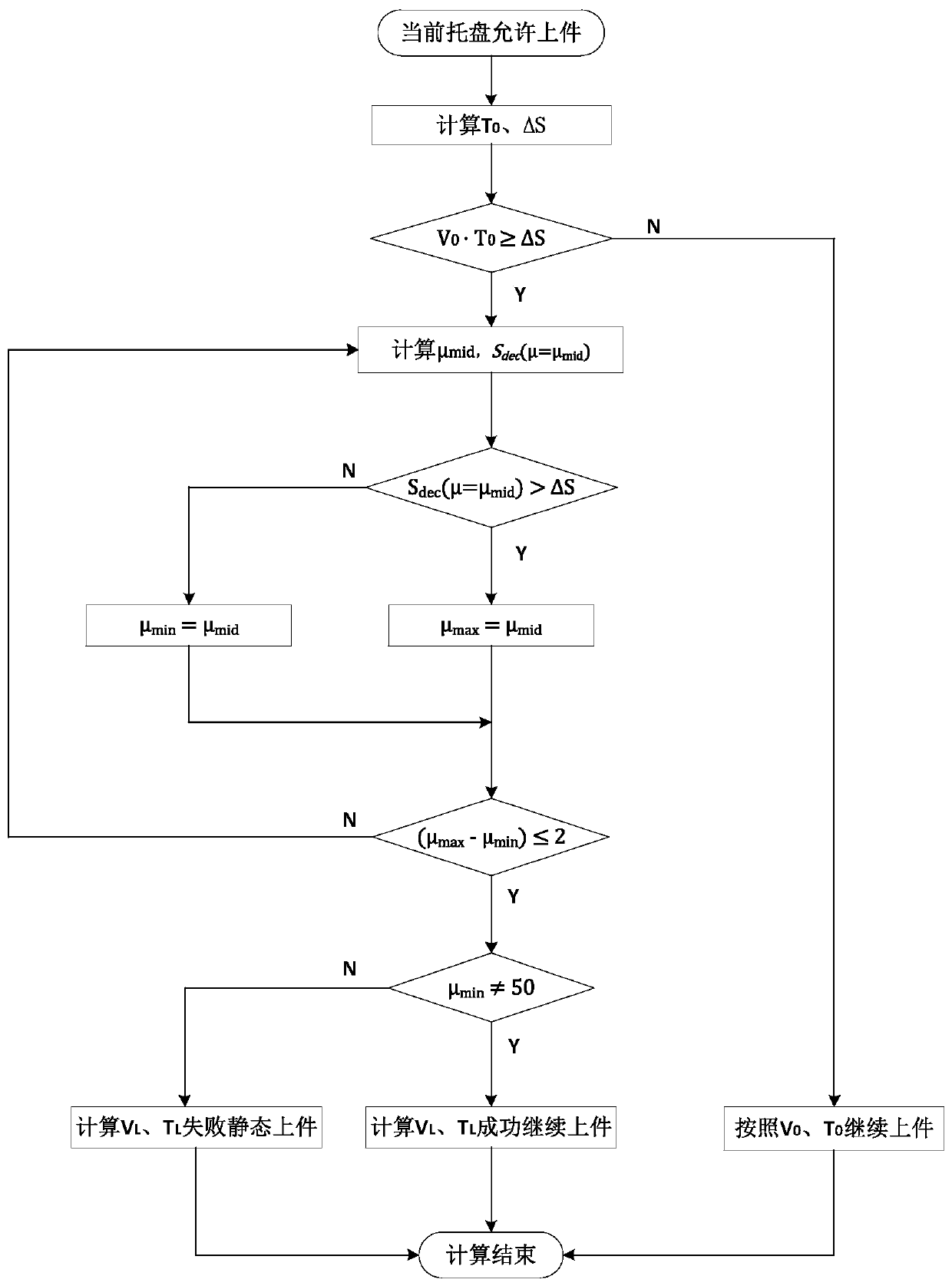

[0083] to V L , T L An approximate fitting solution for .

[0084] For emails that need to adjust parameters, you can first ask for a V L An approximation of:

[0085]

[0086] Use the traditional algorithm to calculate the mail in V′ L Running time T′ at running speed L .

[0087] Since this calculation does not take into account the change from V 0 to V' L The deceleration process when changing, so T L should be greater than T′ L to be long. In actual use, a correction ratio η and Simulate the effects of the deceleration process.

[0088]

[0089]

[0090] n and It is not a linear relationship, and can be adjusted in sections according to the actual situation on site during debugging. in most cases Take 75% to meet the demand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com