Opposite-rotation-cutter-wheel fruit picking device capable of achieving drop-point-controllable collection

A technology of cutter wheel and rotary knife, which is applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve problems such as danger and high labor intensity, and achieve the effects of high fault tolerance, low labor intensity and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The purpose of the present invention will be further described in detail through specific examples below, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

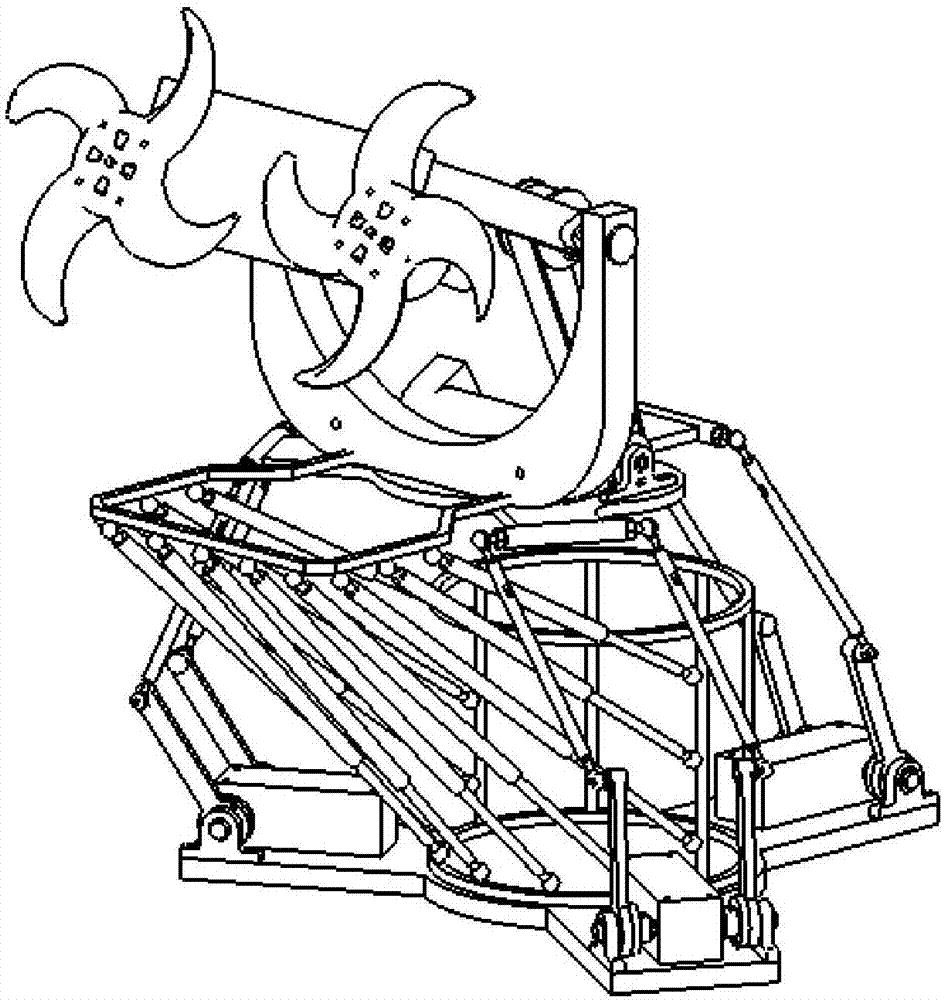

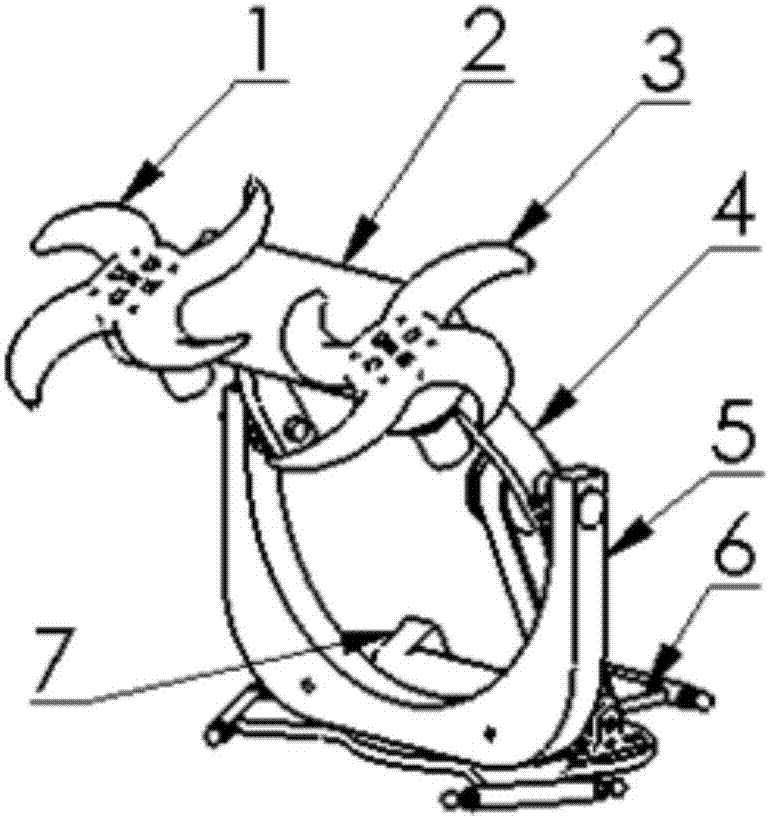

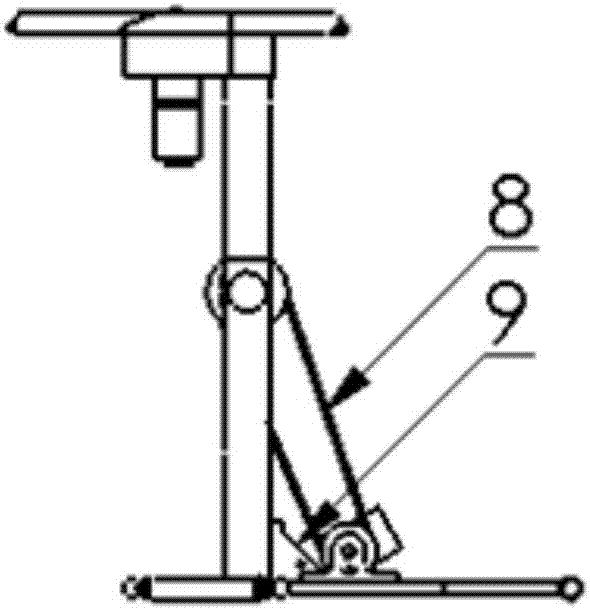

[0038] Such as Figure 1 to Figure 15 As shown, it includes a pitch head, a counter-rotating cutter wheel assembly arranged on the pitch head, a parallel platform assembly arranged at the bottom of the pitch head,

[0039] The counter-rotating cutter wheel assembly includes a left cutter wheel 3, a right cutter wheel 1, a cutter wheel base 2, a turntable 10, and a cutter wheel motor 11, and the left cutter wheel 3 and the right cutter wheel 1 are opposite to each other through the turntable 10 The rotation is arranged on one side of the cutter wheel base 2, and the left cutter wheel 3 and the right cutter wheel 1 are respectively driven and connected with the cutter wheel motor 11 fixed on the other side of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com