A method for improving the oxygen evolution performance of carbon cloth

A technology of oxygen evolution and carbon cloth, which is applied in the field of electrocatalytic oxygen evolution, can solve the problem of high risk factor of experimental reagents, and achieve the effects of improving catalytic ability, reducing cost, and high oxygen evolution activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

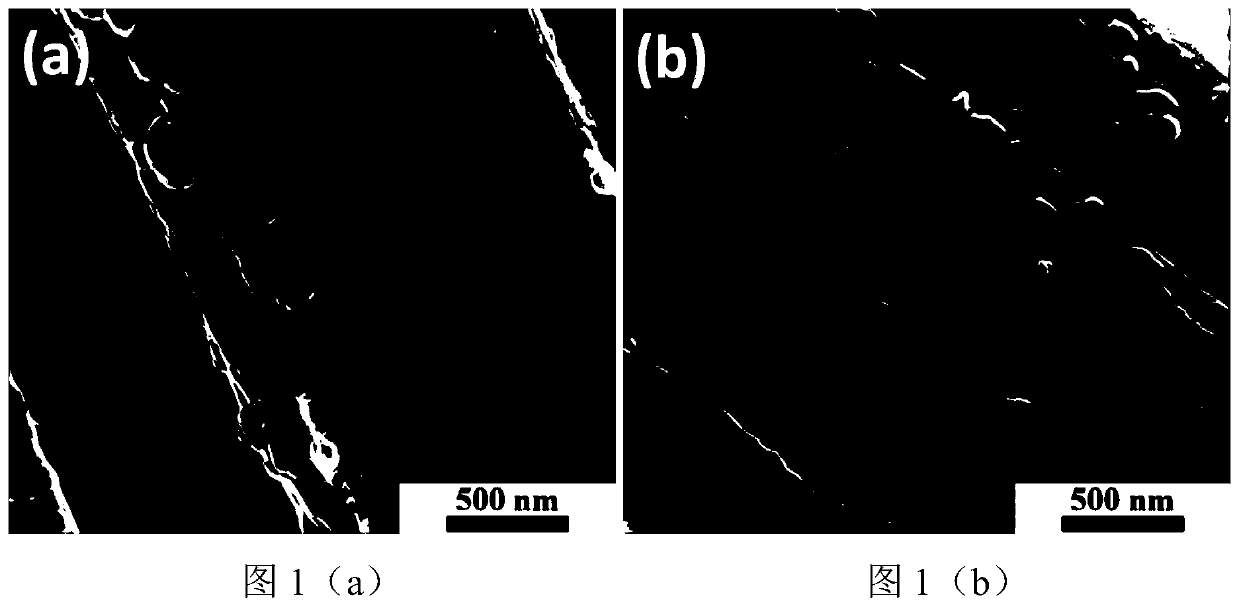

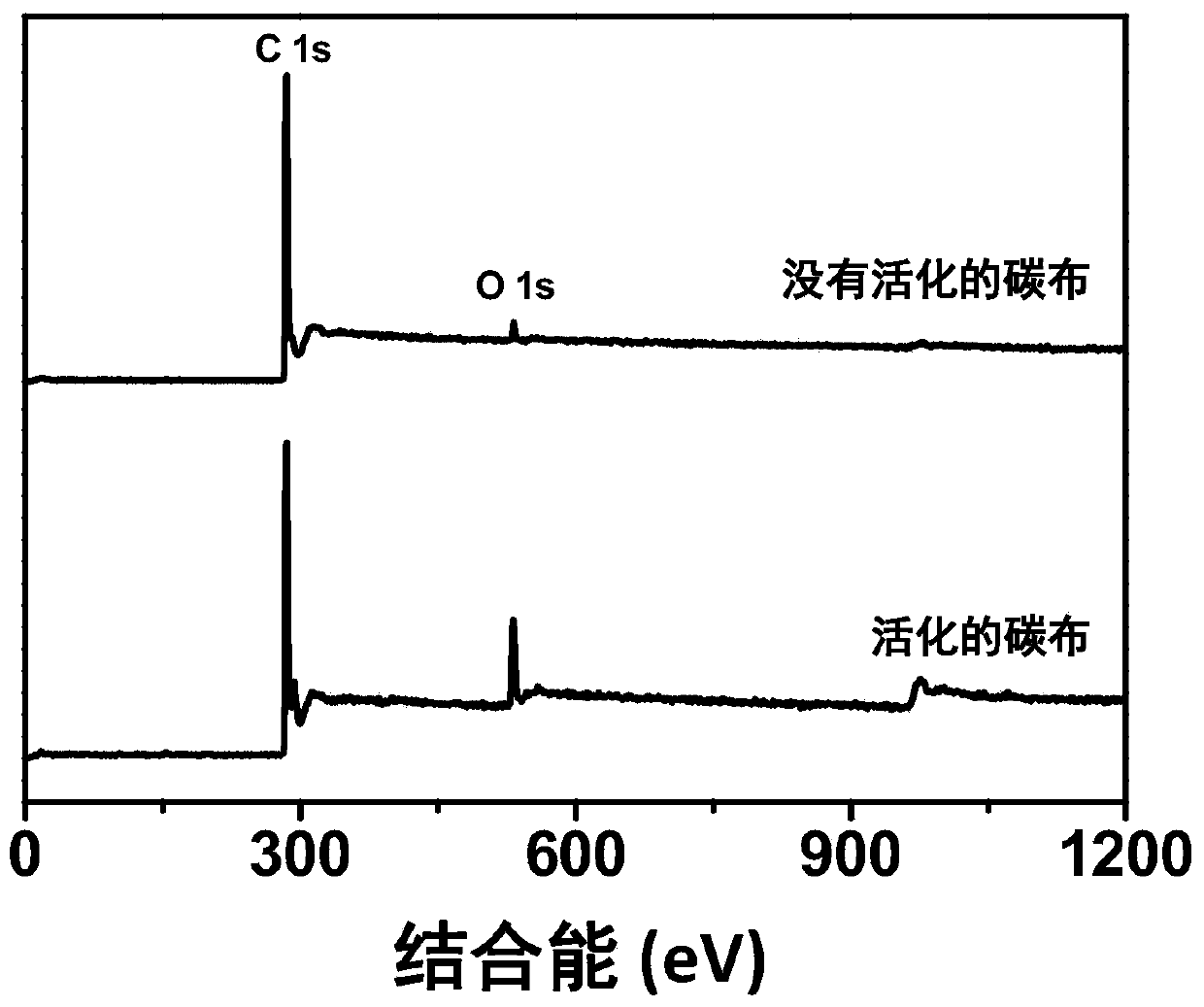

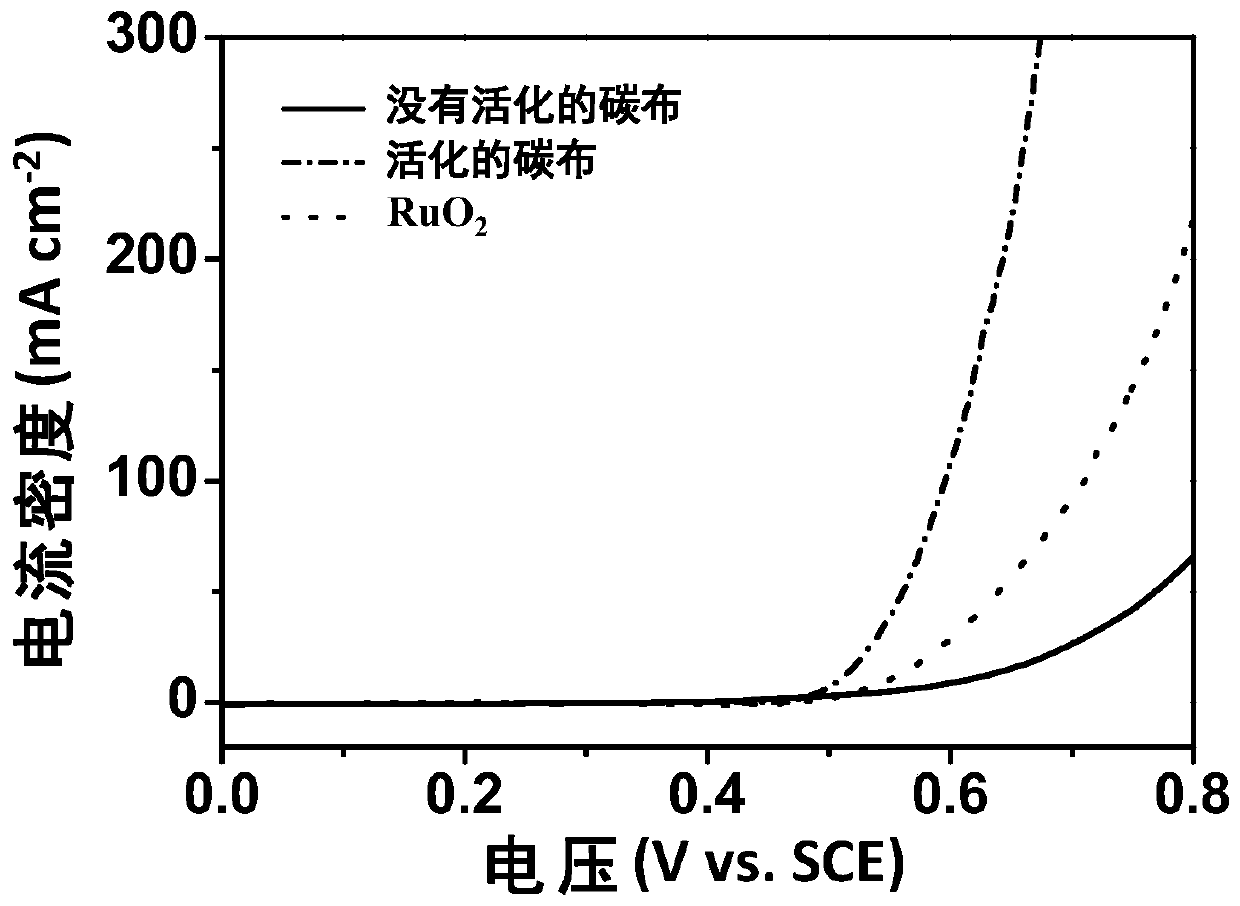

Method used

Image

Examples

Embodiment 1

[0038] A method for improving the oxygen evolution performance of carbon cloth in this embodiment includes the following steps:

[0039] (1) Add 363.8mg of vanadium pentoxide and 756.4mg of oxalic acid into 12ml deionized water respectively (the mass concentration of vanadium pentoxide in deionized water is 30.32mg / mL, the molar ratio of vanadium pentoxide to oxalic acid 1:3), in an oil bath at 75°C, the two are fully reacted to form a dark blue vanadyl oxalate solution;

[0040] (2) Cool the solution prepared in step (1) to room temperature, then add 3 mL of hydrogen peroxide (the volume ratio of hydrogen peroxide to deionized water is 1:4), and convert the dark blue vanadyl oxalate solution into brown vanadyl peroxide solution;

[0041] (3) Add 60mL of ethanol (the volume ratio of ethanol to the deionized water is 5:1) to the solution prepared in step (2), then transfer to the hydrothermal reaction kettle of 100mL (the total volume of ethanol and deionized water The volume...

Embodiment 2

[0049] A method for improving the oxygen evolution performance of carbon cloth in this embodiment includes the following steps:

[0050] (1) The oxalic acid of the vanadium pentoxide of 300mg and 623.7mg is added into 10ml deionized water respectively (the mass concentration of vanadium pentoxide in deionized water is 30mg / mL, the molar ratio of vanadium pentoxide and oxalic acid is 1 : 3), in the oil bath of 70 ℃, make both fully react and form dark blue vanadyl oxalate solution;

[0051] (2) Cool the solution prepared in step (1) to room temperature, then add 2.5 mL of hydrogen peroxide (the volume ratio of hydrogen peroxide to deionized water is 1:4), and convert the dark blue vanadyl oxalate solution into brown oxygen peroxide Vanadium solution;

[0052] (3) Add 60mL of ethanol (the volume ratio of ethanol to the deionized water is 6:1) to the solution prepared in step (2), then transfer to the hydrothermal reaction kettle of 100mL (the total volume of ethanol and deioniz...

Embodiment 3

[0056] A method for improving the oxygen evolution performance of carbon cloth in this embodiment includes the following steps:

[0057] (1) The oxalic acid of the vanadium pentoxide of 420mg and 873.2mg is added into 12ml deionized water respectively (the mass concentration of vanadium pentoxide in deionized water is 35mg / mL, the molar ratio of vanadium pentoxide and oxalic acid is 1 : 3), in the oil bath of 90 ℃, make both fully react and form dark blue vanadyl oxalate solution;

[0058] (2) Cool the solution prepared in step (1) to room temperature, then add 3 mL of hydrogen peroxide (the volume ratio of hydrogen peroxide to deionized water is 1:4), and convert the dark blue vanadyl oxalate solution into brown vanadyl peroxide solution;

[0059] (3) Add 60mL of ethanol (the volume ratio of ethanol to the deionized water is 5:1) to the solution prepared in step (2), then transfer to the hydrothermal reaction kettle of 100mL (the total volume of ethanol and deionized water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com