Manufacturing method of intraformationall heterogeneous core capable of realizing separated injection and separated production, and experimental method thereof

A technology of production method and experimental method, which is applied in the preparation of test samples, analysis materials, sampling, etc., can solve the problems of inhomogeneous core sweeping conditions and recovery degree cannot be quantitatively evaluated in layers, and achieve reliable experimental data, The effect of simple production process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

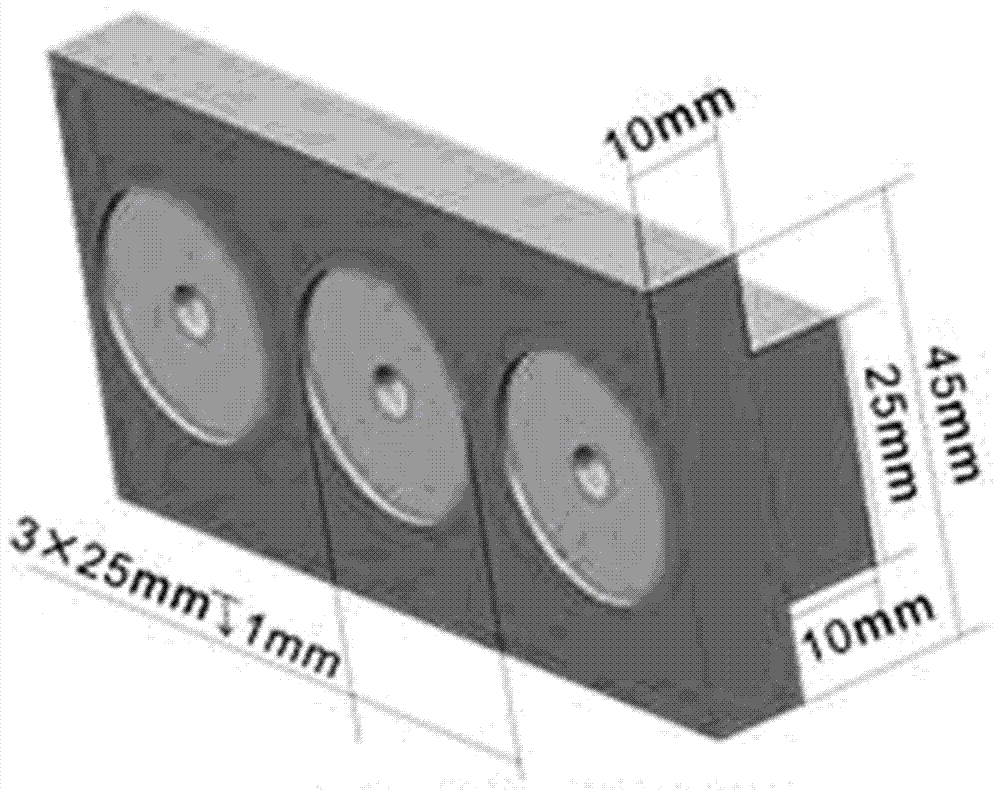

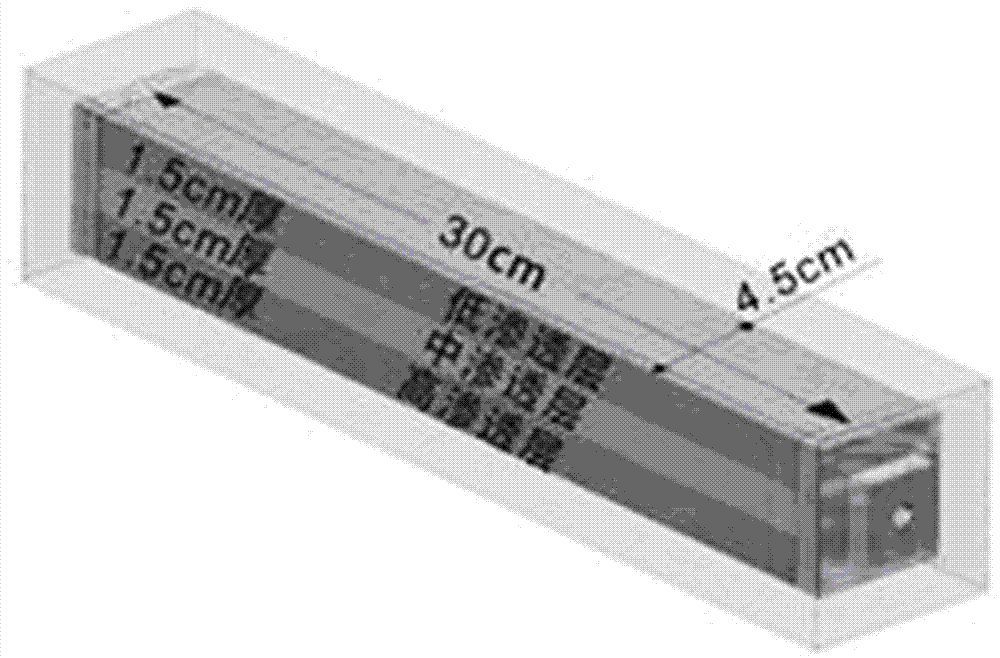

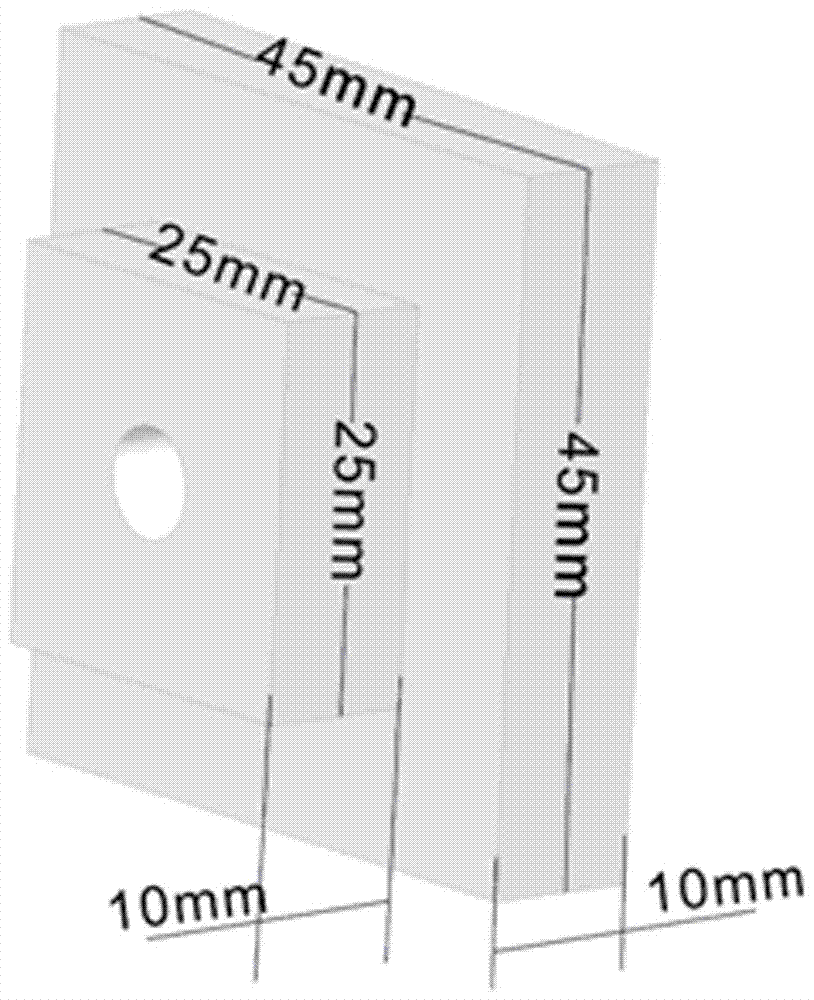

[0035] Referring to each figure, the actual reservoir can be divided into two types: intralayer heterogeneity and interlayer heterogeneity. The former refers to the difference in vertical permeability of the reservoir, and the latter refers to the difference in vertical permeability of the reservoir and There is an impermeable compartment in between. In order to simulate the above two types of reservoirs, the laboratory developed intralayer heterogeneous cores (see image 3 ) and interlayer heterogeneous cores (see Image 6 ), which are used for profile control and water shutoff agent screening and injection process parameter optimization for intralayer heterogeneous reservoirs and interlayer heterogeneous reservoirs, respectively. For the physical simulation of interlayer heterogeneous cores, the injection-production method of "combined injection and separate production, or separate injection and separate production" can be used to understand the diversion rate, water conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com