Hydraulic automatic tensioning device for motor head accessory

A front-end accessory and tensioner technology, applied in the field of hydraulic automatic tensioners, can solve the problems affecting the service life of the tensioner and the large radial size of the automatic tensioner, and achieve good longitudinal guiding rigidity and radial size. Small, long-life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The purpose of the invention of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the embodiments cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following embodiments.

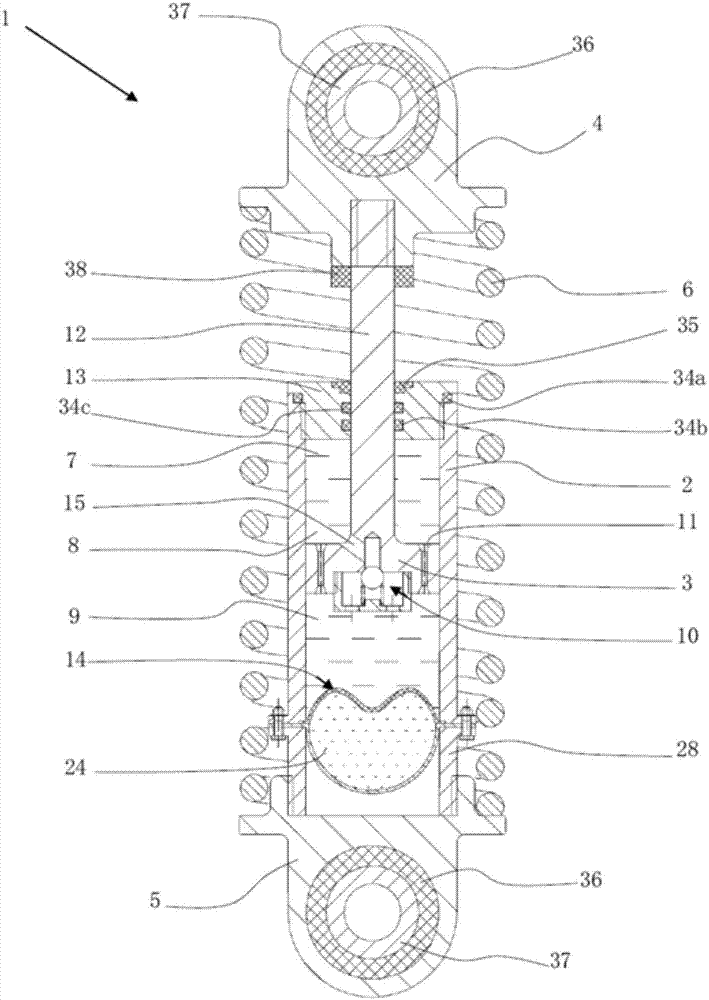

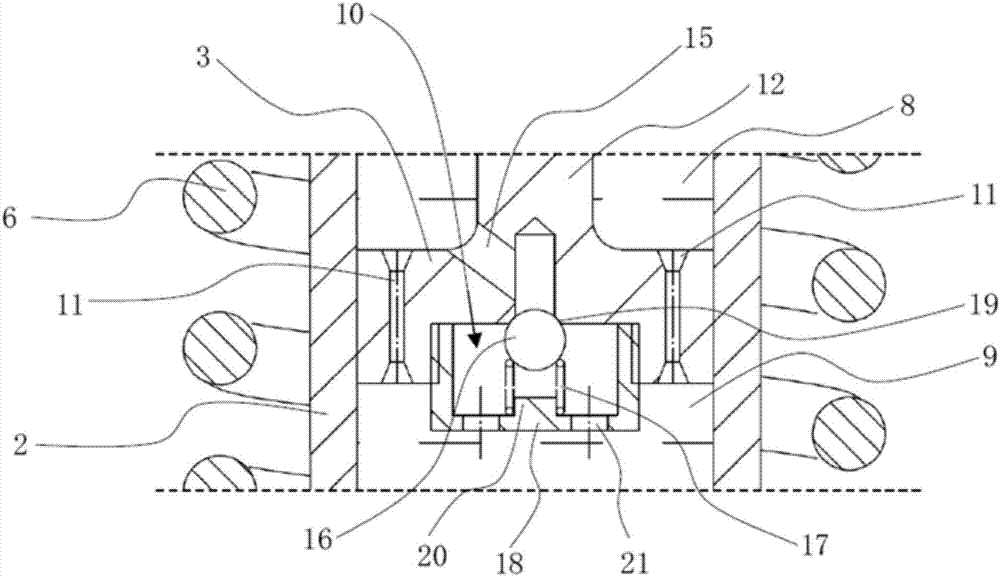

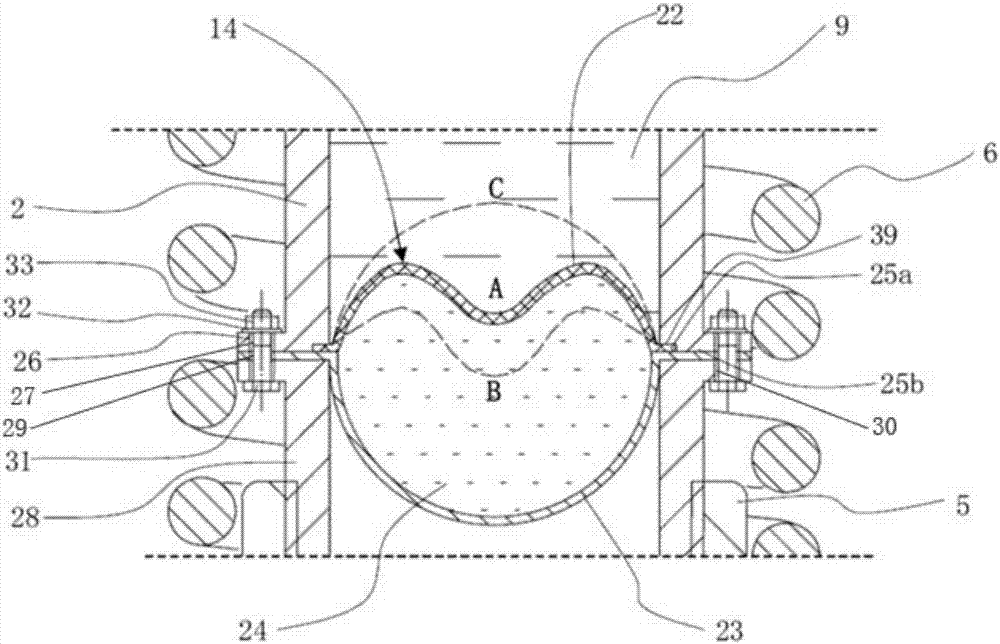

[0030] Such as figure 1 As shown, a hydraulic automatic tensioner attached to the front end of the engine, the automatic tensioner 1 includes a cylinder 2, a piston 3, an upper connector 4, a lower connector 5, a spring coil spring 6, hydraulic oil 7, and a sealing unit 13 and air storage chamber 14. The cylinder body 2 is cylindrical, with openings at both ends of the cylinder body 2, one end of the opening is sealed by the sealing unit 13, and the other end of the opening is sealed by the close fit of the air storage chamber 14 and the transition piece 28, and the transition piece 28 It is connected with the lower connecting piece 5 through scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com