Resin special for plastic suction molding of transparent broad molecular weight-distributed random copolymer polypropylene and preparation method of resin

A technology of wide molecular weight distribution and random copolymerization, which is used in the field of special resin and preparation for transparent wide molecular weight distribution random copolymer polypropylene plastic molding, and achieves the effects of easy processing, good fluidity and improved transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

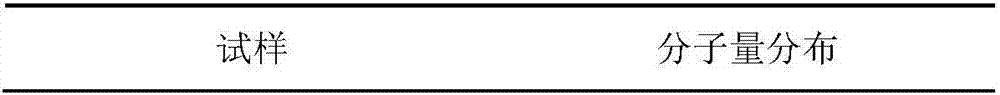

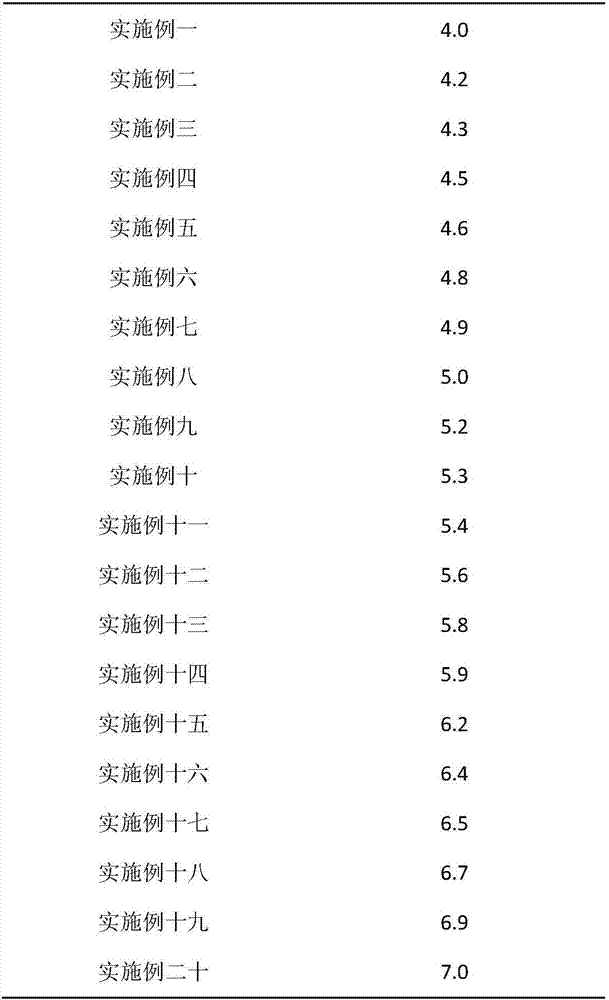

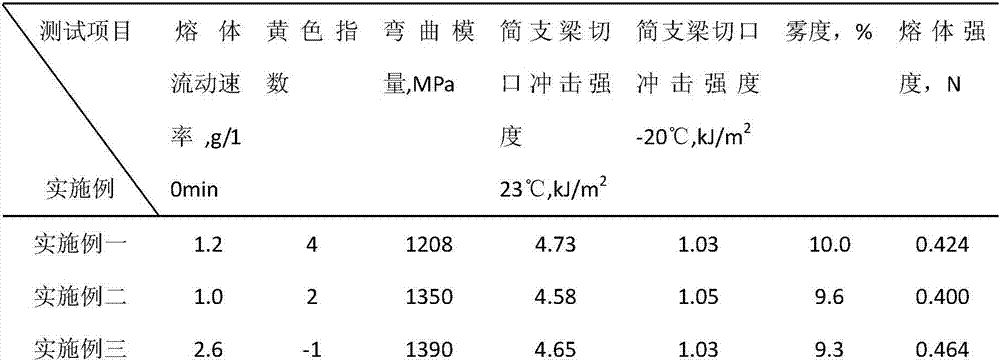

[0027] In the single-loop polypropylene unit of LBI company Spheripol process, a new type of wide molecular weight distribution catalyst NDQ (activity is 21000g polypropylene / g catalyst) is used first, and the NDQ catalyst is provided by Beijing Research Institute of Chemical Industry (the same below); Liquid propylene and ethylene with a purity of 99.9%, with ethylene addition of 0.2%wt, produce a random copolymer polypropylene base resin with a wide molecular weight distribution (Mw / Mn=4.0-7.0), and a melt index of 1.0-3.0g / 10min; Then, in the random copolymerized polypropylene base resin with a wide molecular weight distribution (Mw / Mn=4.0~7.0), by adding an auxiliary auxiliary system such as a transparent agent, the transparency and the low yellowness index are improved, and a low yellowness index is produced. Transparent wide molecular weight distribution random copolymer polypropylene thermoforming resin. The high-efficiency additive system is expressed in parts by weigh...

Embodiment 2

[0029] In LBI company Spheripol process single-loop polypropylene device, first adopt novel wide molecular weight distribution catalyst NDQ (activity is 22000g polypropylene / g catalyst); add the liquid propylene with purity of 99.7% and the ethylene of purity 99.9%, the addition amount of ethylene is 0.3%wt, produce random copolymerized polypropylene base resin with wide molecular weight distribution (Mw / Mn=4.0~7.0), melt index is 1.0~3.0g / 10min; then wide molecular weight distribution (Mw / Mn=4.0~ 7.0) to the base resin of random copolymerized polypropylene, by adding auxiliary additive systems such as clarifiers, the transparency is improved and the low yellowness index is reduced to produce a low yellowness index, high transparency, wide molecular weight distribution, random copolymerized polypropylene thermoforming special resin. The high-efficiency auxiliary system is expressed in parts by weight. The raw material of wide molecular weight distribution random copolymerized ...

Embodiment 3

[0031] In LBI company Spheripol process single-loop polypropylene unit, first adopt novel broad molecular weight distribution catalyst NDQ (activity is 23000g polypropylene / g catalyst); add the liquid propylene with purity of 99.7% and the ethylene of purity 99.9%, the addition amount of ethylene is 0.4%wt, to produce a random copolymerized polypropylene base resin with a wide molecular weight distribution (Mw / Mn=4.0~7.0), the melt index is 1.0~3.0g / 10min; 7.0) to the base resin of random copolymerized polypropylene, by adding auxiliary additive systems such as clarifiers, the transparency is improved and the low yellowness index is reduced to produce a low yellowness index, high transparency, wide molecular weight distribution, random copolymerized polypropylene thermoforming special resin. The high-efficiency auxiliary system is expressed in parts by weight. The raw material of wide molecular weight distribution random copolymerized polypropylene resin is 100 parts, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com