Bundling machine

A baler and thread technology, which is applied in the direction of bundling materials, etc., can solve the problems of wire rod breakage, reduction of baling efficiency, and loose bundling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

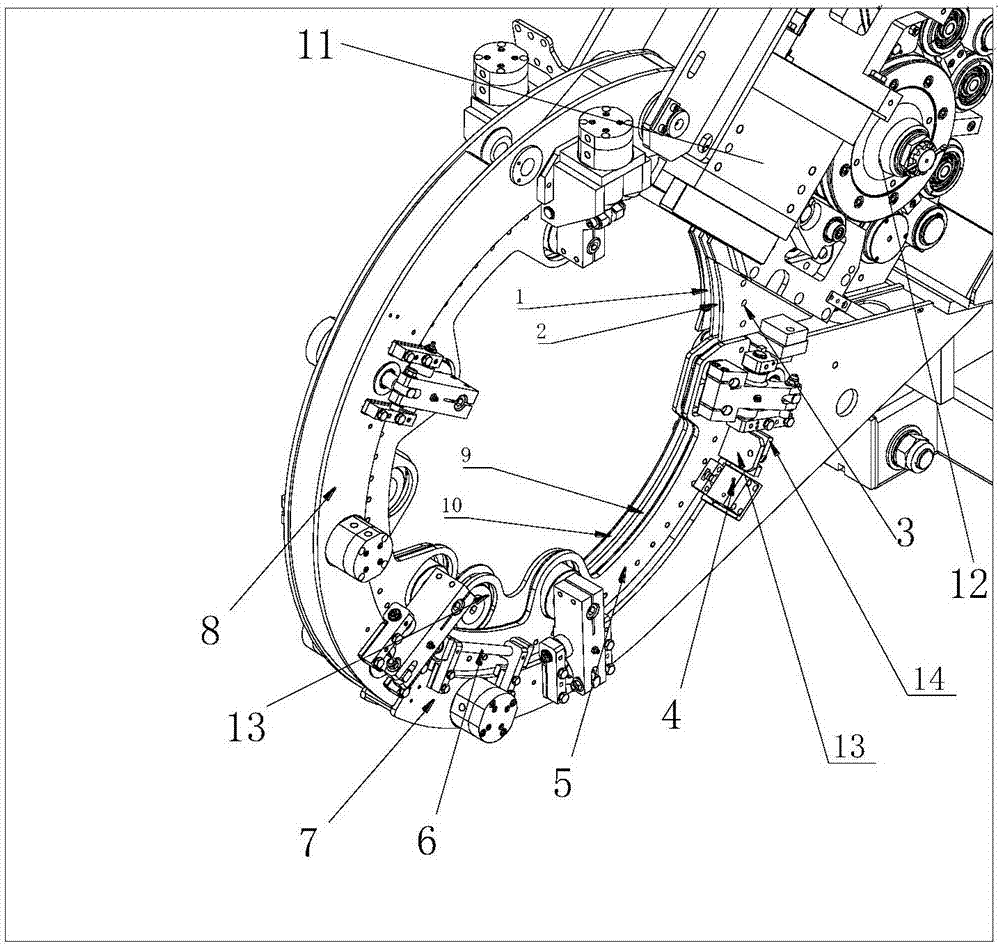

[0011] like figure 1 As shown, the tying machine of the present invention includes a wire feeding and drawing mechanism 12, a twisting and shearing mechanism 11, and a wire storage disk mechanism, wherein the wire feeding and drawing mechanism transports the bundled wire to the wire storage disk mechanism, and when the bundled wire is in place, reverse Tightening mainly includes a transmission motor, a driving wheel, a driven wheel group and an elastic adjustment mechanism; the output shaft of the transmission motor is connected with the driving wheel to drive the driving roller to rotate; the driven wheel group is attached to the driving wheel, and the The elastic adjustment mechanism is connected with the driven wheel group, and the twisting and shearing mechanism is used for knotting and cutting the bundled silk. The twisting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com