Flow type train towing vehicle

A tractor, mobile technology, applied in the direction of railway vehicle traction device, railway car body parts, transportation and packaging, etc., can solve the problems of limited traction capacity, inconvenient marshalling of traction equipment, high cost of manufacturing and use, and achieve the reduction of self-weight Restriction, meeting different traction load requirements, the effect of large traction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

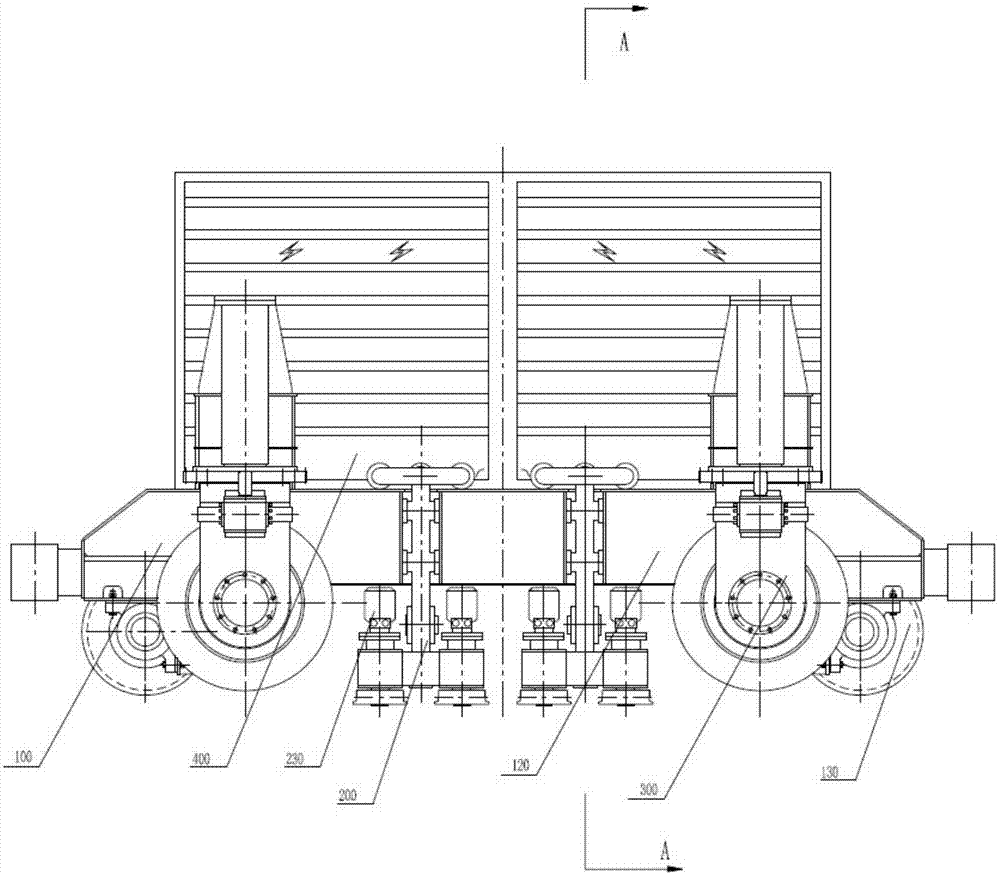

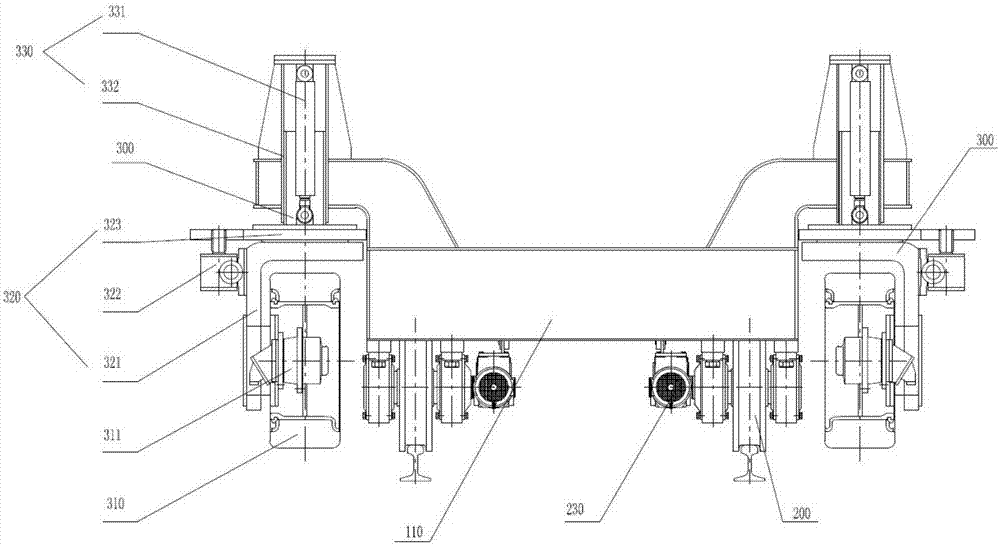

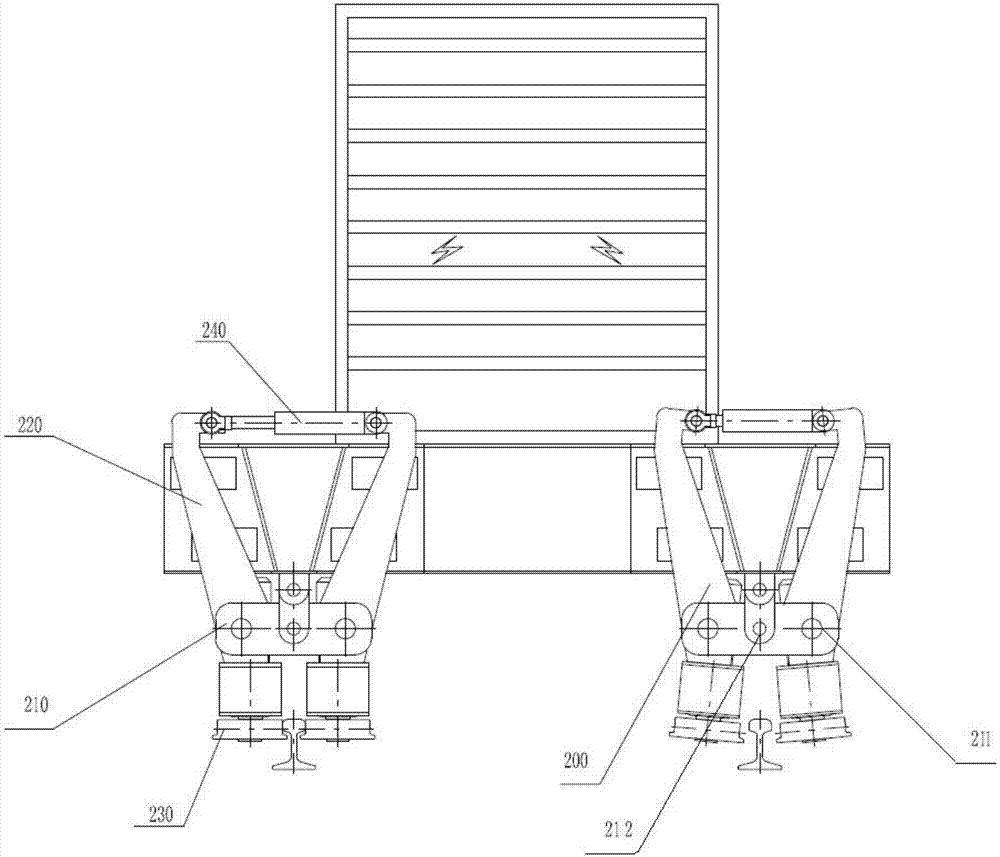

[0028] see figure 1 As shown, the present invention provides a mobile train tractor, including a vehicle frame 100 and a traction device 200, the traction device 200 is installed on the vehicle frame 100, and is used to apply a clamping force to the rail and drive the vehicle frame 100 Relative rail movement, so as to achieve the purpose of traction.

[0029] Wherein, the vehicle frame 100 of the present invention includes a connecting arm 110 and two longitudinal beams 120 , the two longitudinal beams 120 are arranged in parallel and spaced apart, and the two longitudinal beams 120 are connected to each other through the connecting arms 110 to form the vehicle frame 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com